Closed-cycle control system for digital dynamic force moment of DC motor

A DC motor and dynamic torque technology, applied in the field of control systems, can solve problems such as complex circuit structure, high cost, and limited frequency range of system capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

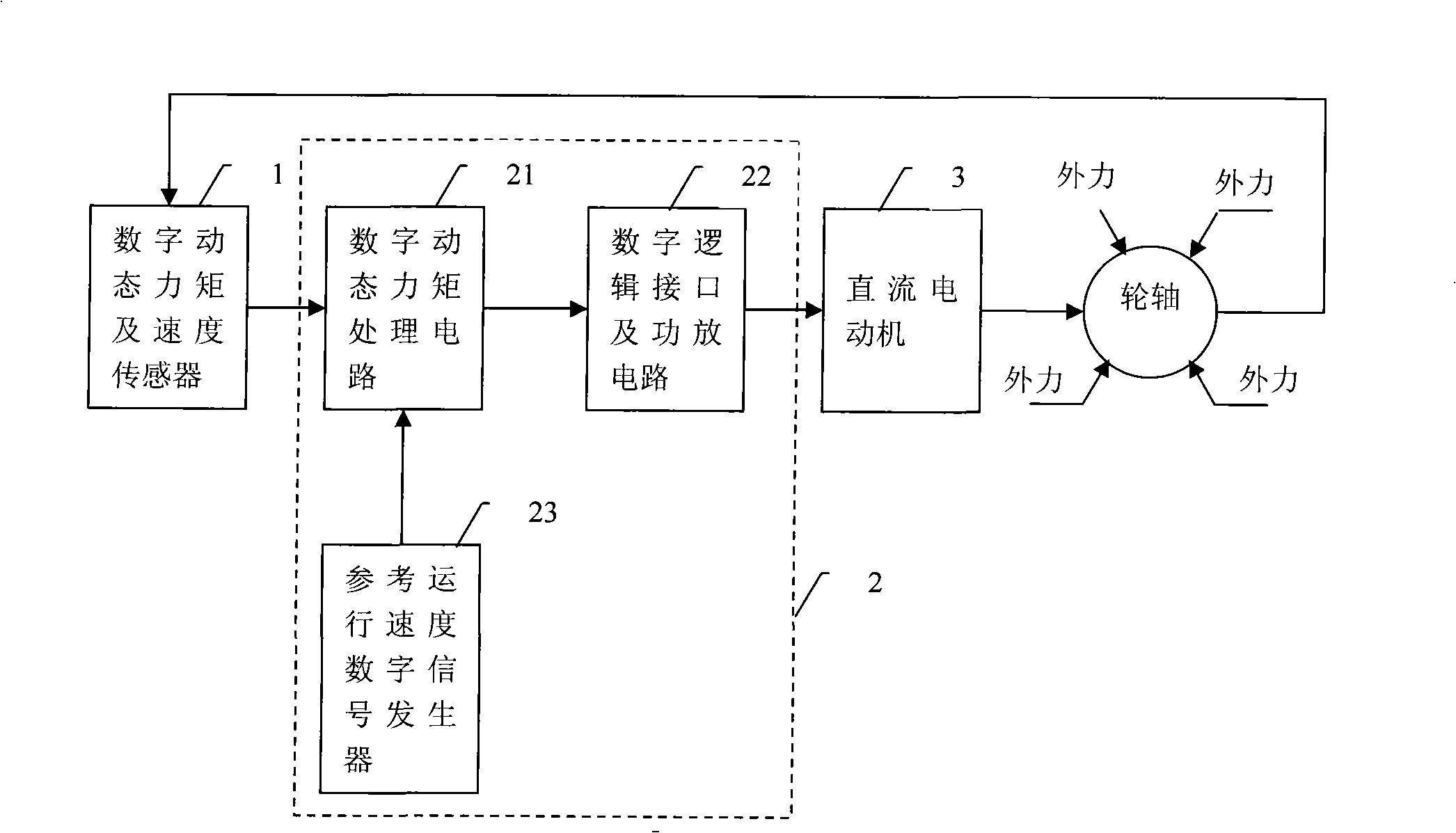

[0025] refer to figure 1 , figure 1 It is a block diagram of a DC motor digital closed-loop control system of the present invention, the DC motor digital closed-loop control system includes a digital sensor 1, a reference speed digital signal generator 23, a digital dynamic torque signal processing circuit 21, a digital logic interface and a power amplifier circuit 22 and a DC motor 3.

[0026] A digital sensor 1, which is coaxial with the motor 3, is used to transmit a dynamic digital pulse signal comprising real-time torque and speed information to the digital dynamic torque signal processing circuit 21;

[0027] The reference speed digital signal generator 23 is used to set the standard speed digital pulse signal of the DC motor, and output the pulse signal as a reference speed pulse signal to the digital dynamic torque signal processing circuit 21;

[0028] The digital dynamic torque signal processing circuit 21 is used to compare the positions of the reference speed pul...

Embodiment 2

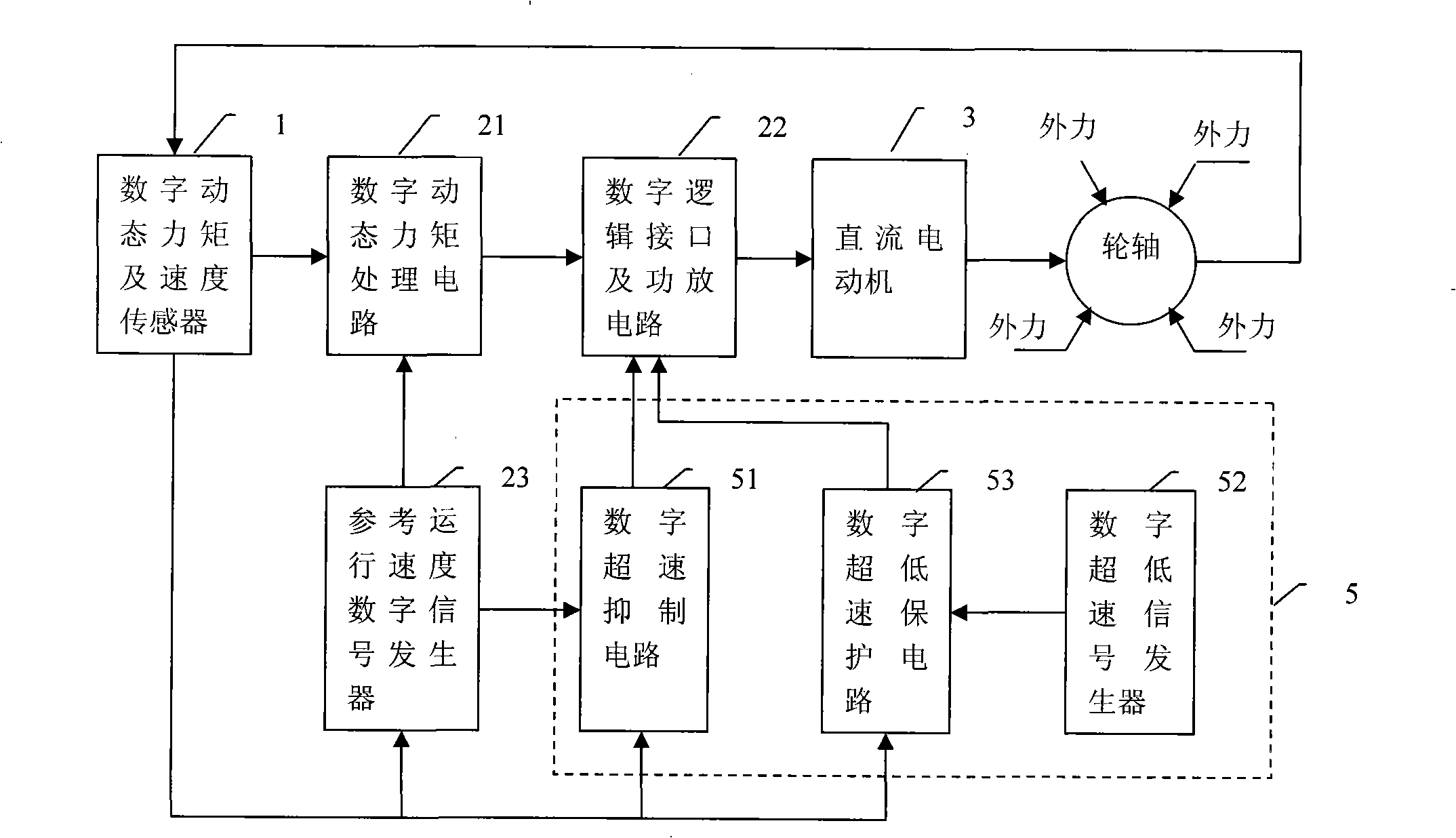

[0033] refer to figure 2 , figure 2 DC motor digital closed-loop control system structural block diagram, add protection circuit 5 on the structure of preceding example, protection circuit 5 comprises overspeed digital suppression circuit 51, ultra-low speed digital signal generator 52 and ultralow speed digital protection circuit 53; Overspeed suppression circuit 51, receiving The real-time speed pulse signal sent by the digital sensor 1 and the reference speed pulse signal sent by the reference speed signal generator 23 compare the real-time speed pulse signal with the preset speed pulse signal, and when the real-time speed is higher than the preset speed, the The monostable circuit continuously sends a short pulse width closing signal to the digital logic interface circuit 22, thereby suppressing the overspeed phenomenon and making the motor return to the normal running speed; the ultra-low speed digital signal generator 52 presets the ultra-low speed digital Pulse signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com