Box-girder moving trolley

A trolley and box girder technology, which is applied in the field of box girder mobile trolleys, can solve the problem of inconsistent running speeds of rigid and soft cars on both sides of the guide rails, and achieve the effect of simple implementation and consistent movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

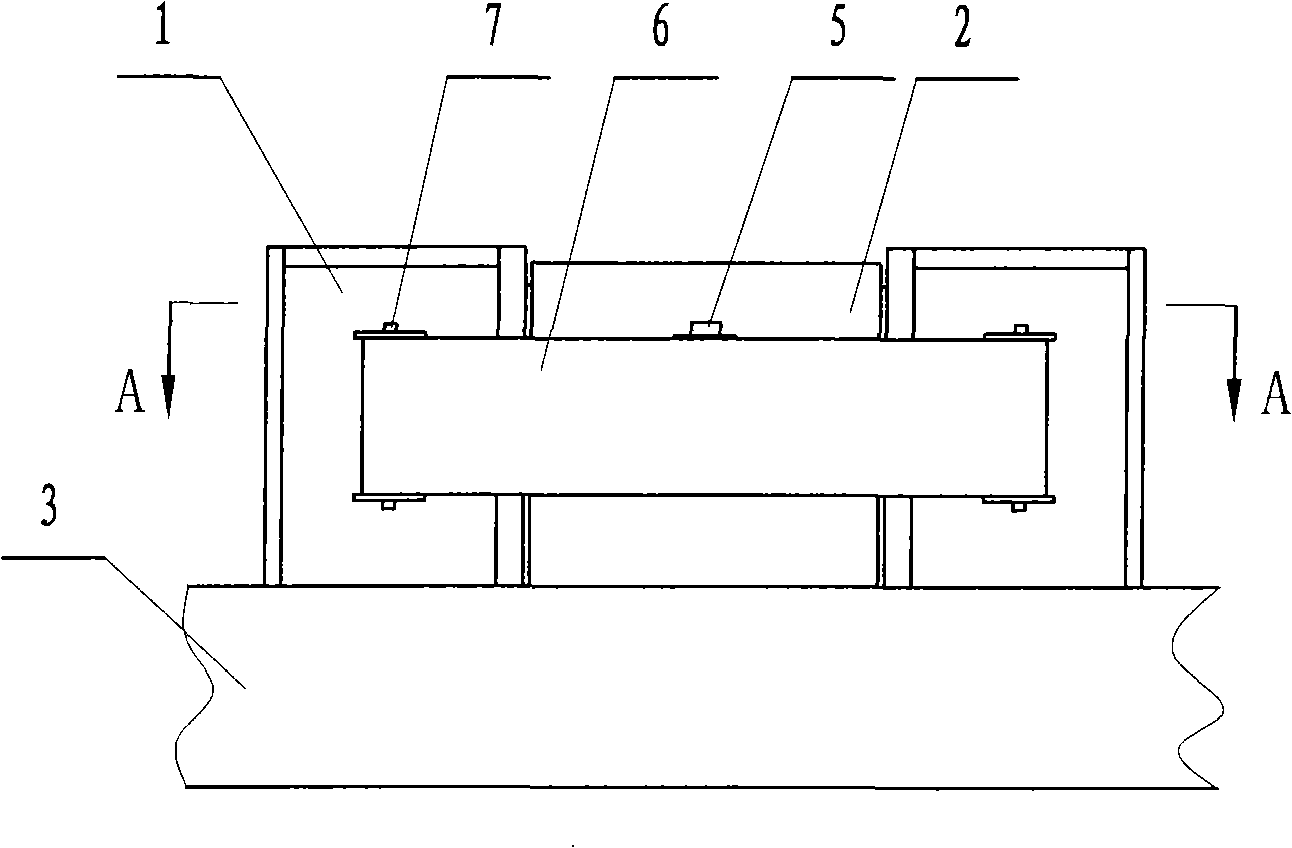

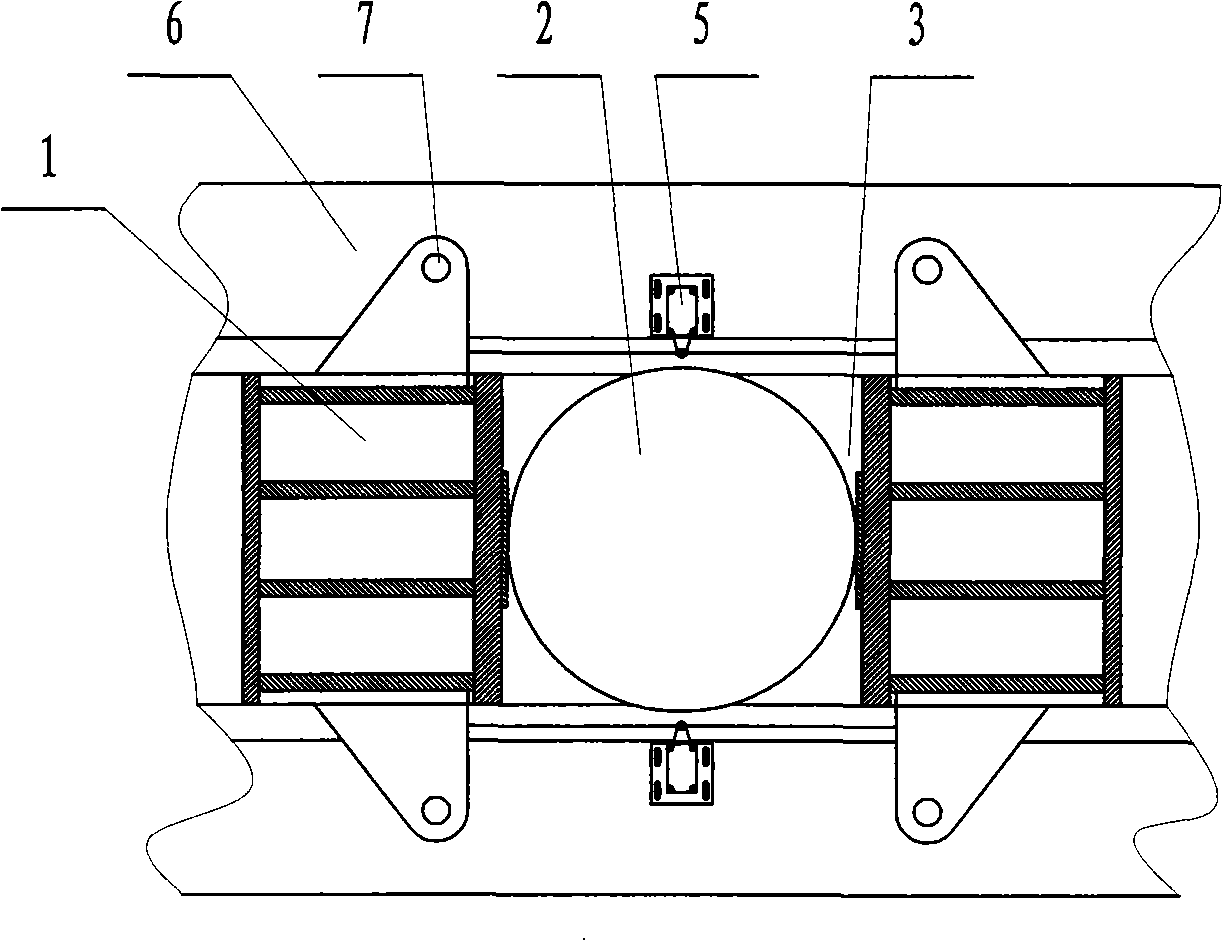

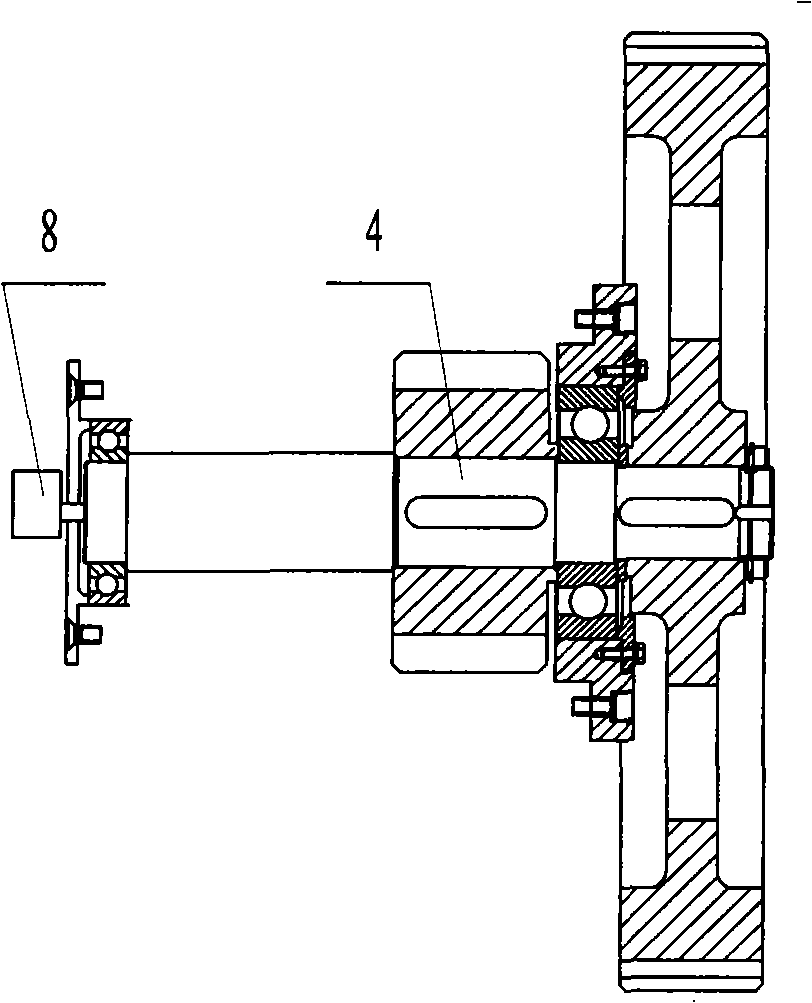

[0018] Such as Figure 1 to Figure 4 It is an embodiment of the box girder mobile trolley of the present invention. The box girder mobile trolley includes a large support 1, an oil top 2, a support beam 3, and a driving shaft assembly 4. The oil top 2 is placed on the support beam 3, and the A large support 1 is respectively arranged at the front and back of the oil top 2, and the large support 1 is arranged on the support beam 3, and an encoder 8 is installed on one side of the drive shaft assembly 4; Two sets of travel switches 5 connected to the control system; the travel switches 5 are arranged in the middle of the upper end surface of the support beam 3; and stop beams 6 are also included, and the stop beams 6 are respectively set on the left and right sides of the oil top 2, with two ends Connected to the large support 1; the travel switch 5 is arranged in the middle of the stop beam 6; both ends of the stop beam are connected to the large support 1 through connecting pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com