Vacuum generating unit

一种产生单元、真空的技术,应用在泵元件、吸杯、连接构件等方向,能够解决气压供给阀不可能转换到阀关闭状态、不能进行工件、保持等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

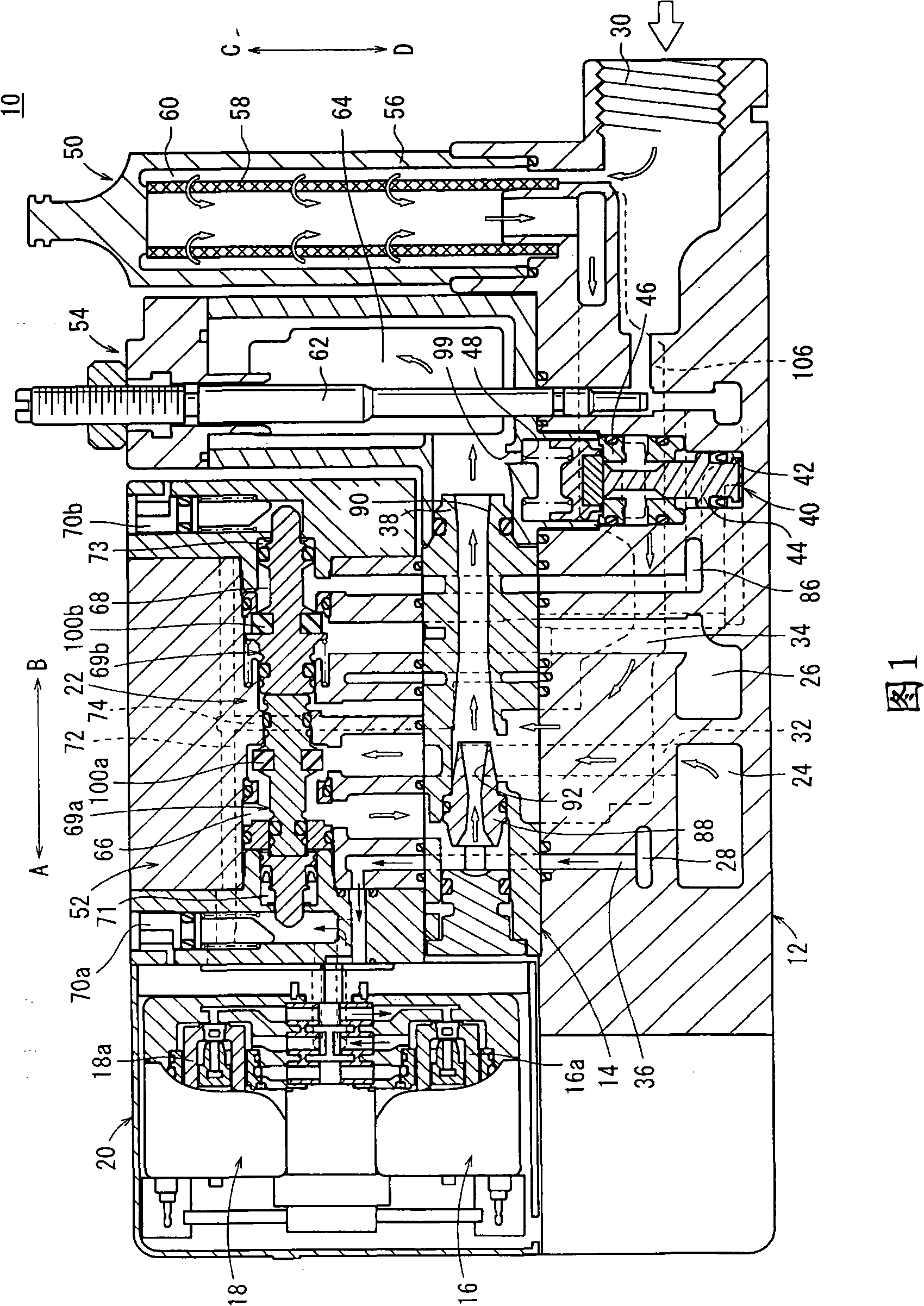

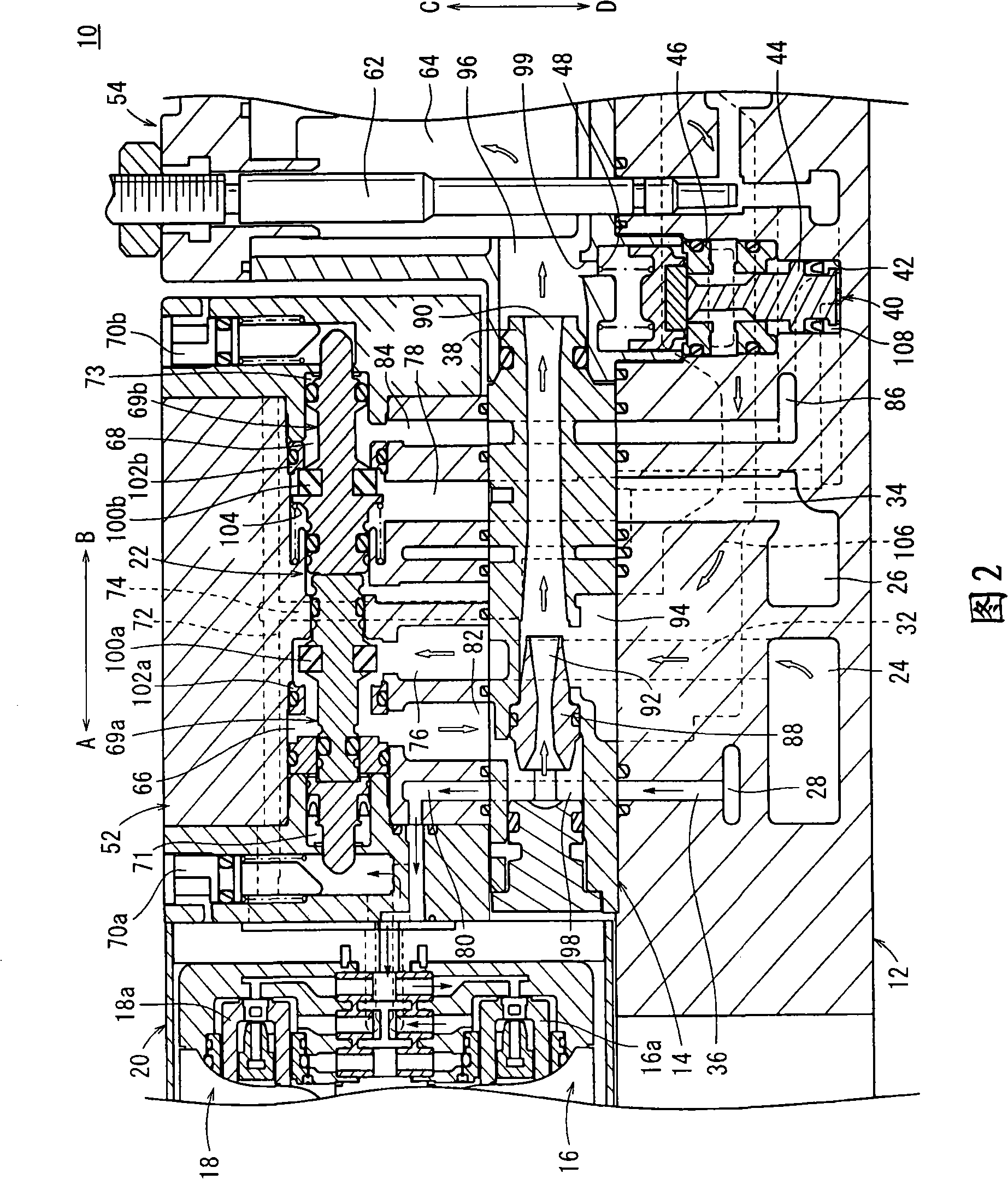

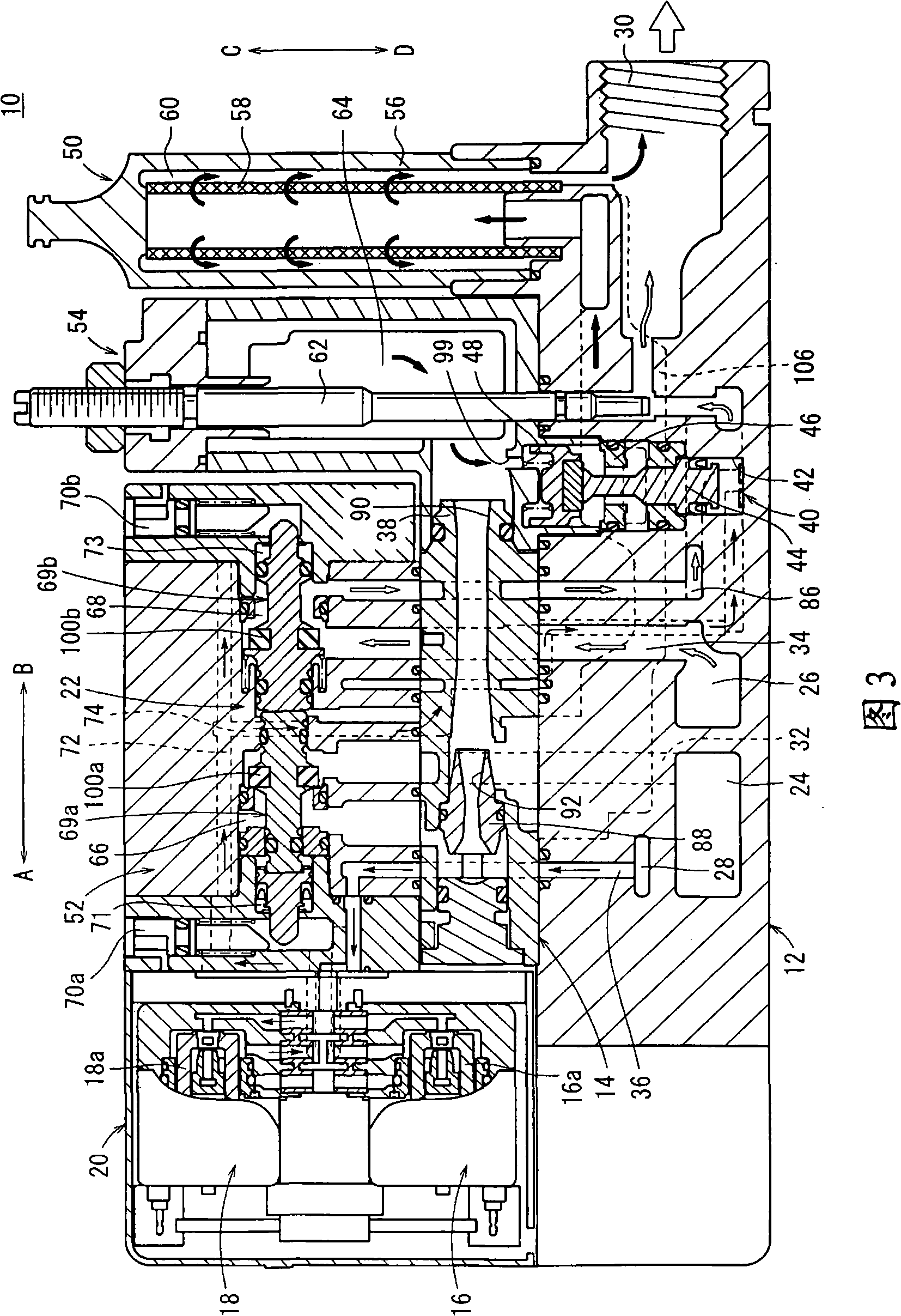

[0019] In FIG. 1, reference numeral 10 denotes a vacuum generating unit of an embodiment of the present invention.

[0020] As shown in FIGS. 1 to 4 , the vacuum generating unit 10 includes a main body 12 formed with a predetermined length; an ejector 14 connected to the top of the main body 12 and serving as a vacuum generating mechanism; disposed at a side of the ejector 14 and having a pilot supply valve 16 and the solenoid valve part 20 of the pilot vacuum disconnect valve 18; arranged on the upper part of the injector 14, moved under the supply of pilot air, for disconnecting the vacuum generating condition that generates negative pressure from the vacuum that releases the negative pressure to the air pressure Switching valve section 22 for switching between conditions.

[0021] The main body 12 has a predetermined length in the longitudinal direction (directions of arrows A and B), wherein on one side of the main body 12, there are provided a supply port 24 for supplying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com