Energy-saving, scaling-free and anti-corrosion MVR low-temperature evaporation system for high-salinity wastewater treatment and use method thereof

A high-salt wastewater and low-temperature evaporation technology, applied in the field of MVR low-temperature evaporation system, can solve the problems of insufficient corrosion resistance of equipment, increase the service life of energy consumption, and easy scaling and clogging, so as to reduce energy consumption and reduce energy consumption , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

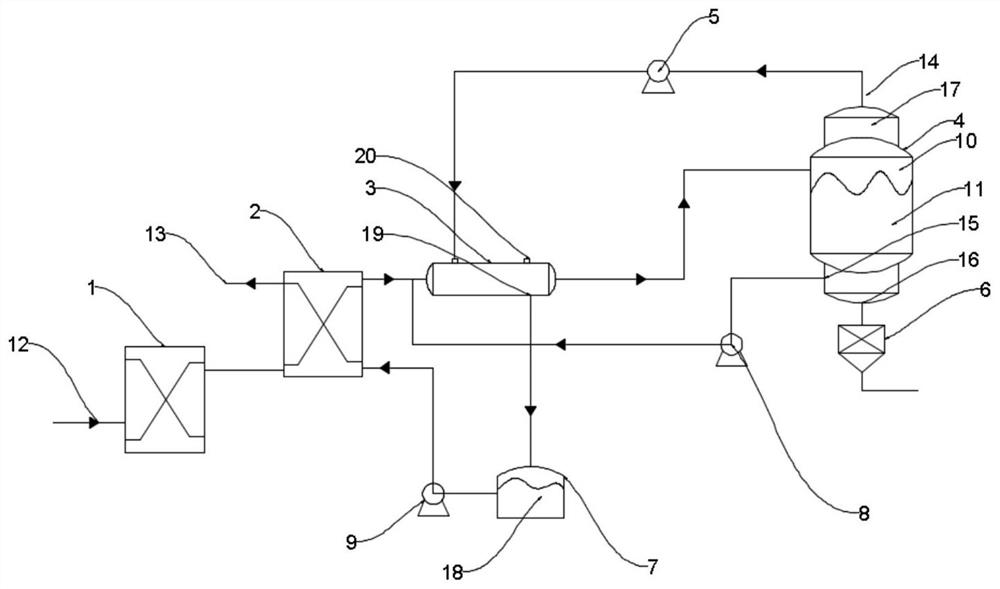

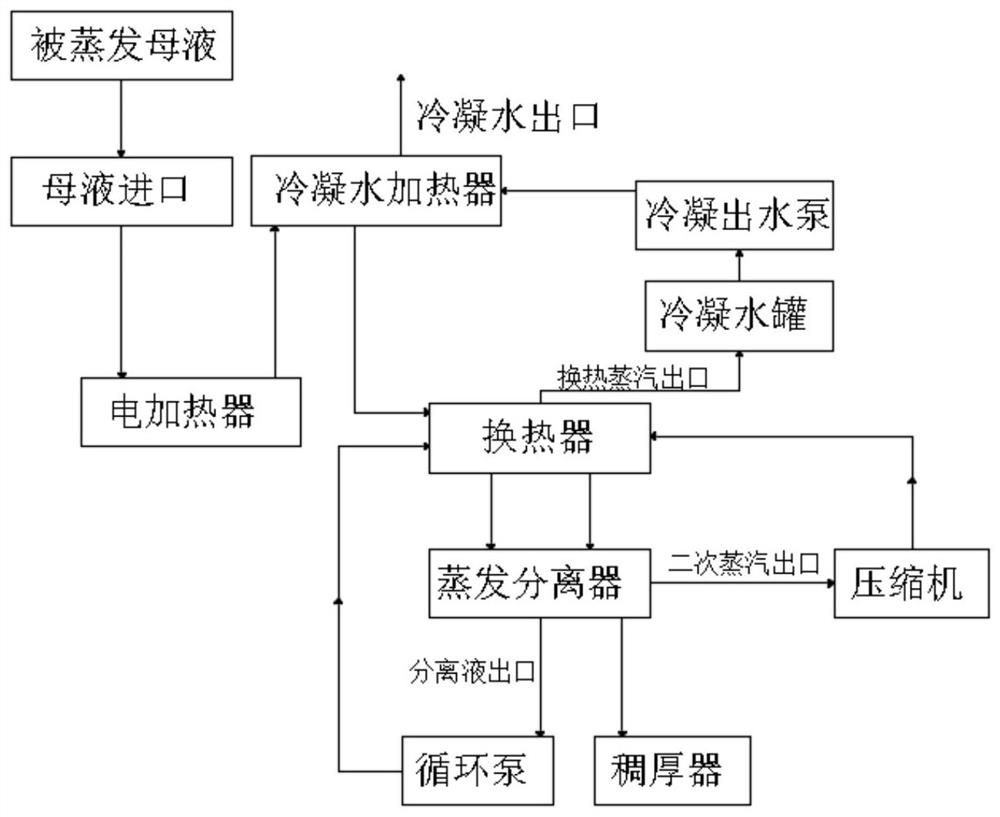

[0025] see Figure 1-2 , an embodiment provided by the present invention: an MVR low-temperature evaporation system for energy-saving, non-scaling, anti-corrosion and high-salt wastewater treatment and its use method, including an electric heater 1, a condensate heater 2 is arranged at the front end of the electric heater 1, A heat exchanger 3 is installed at the outlet of the front end of the condensate heater 2, and the heat exchanger 3 is composed of one or more heat exchangers 3 connected in parallel, and an evaporative separator 4 is installed at the outlet of one side of the heat exchanger 3, and the evaporative separation The device 4 is composed of one or mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com