Water curtain dust removing mechanism

A technology of water curtain dust removal and water accumulation area, which is applied in the direction of dispersed particle separation, chemical instruments and methods, and the use of liquid separation agents, etc., which can solve the negative pressure of the coating pan that affects the gas processing capacity, wastes time and labor, and affects work efficiency. and other issues, to achieve significant technological progress, high work efficiency, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

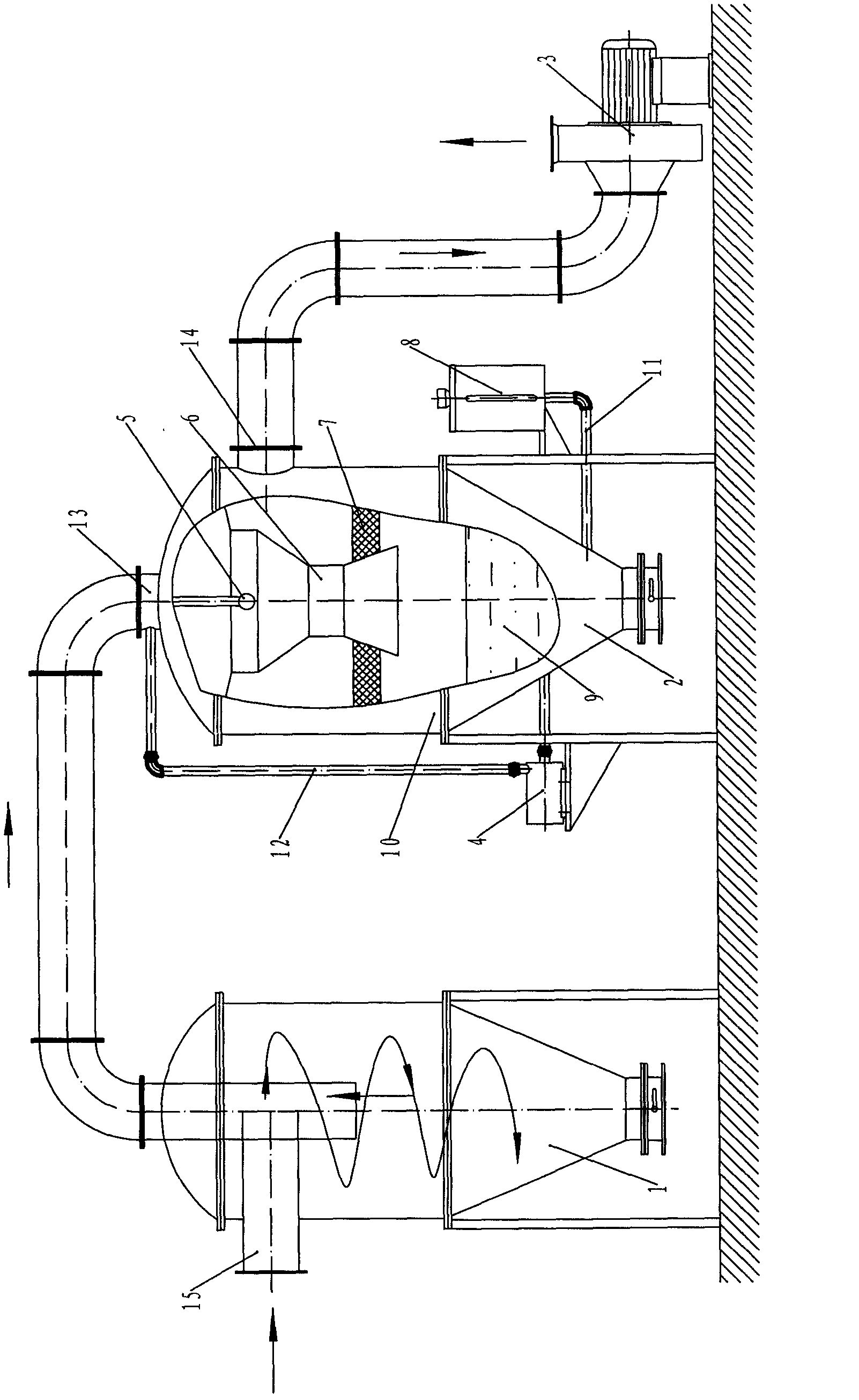

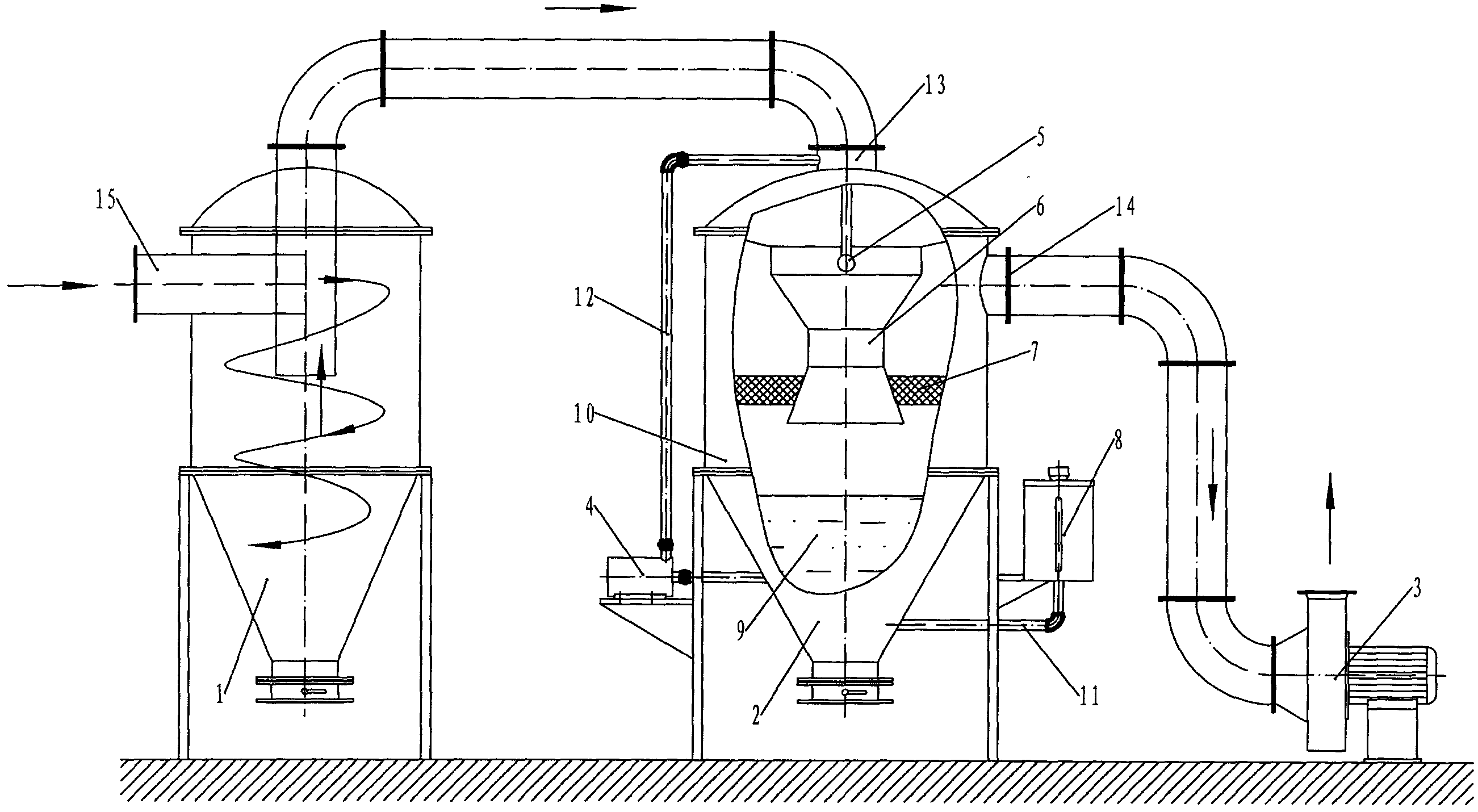

[0009] refer to figure 1 As can be seen, the present invention is applied to a water curtain dedusting mechanism of a coating machine, comprising a housing 10, an atomizing shower head 5 is housed at an upper inlet 13 in the housing 10, and in the housing 10, and An air pipe 6 is installed near the bottom of the atomizing shower head; a water-gas separation device 7 is installed in the housing 10 and at the outlet of the air pipe 6, and the bottom of the housing 10 is a water accumulation area 9.

[0010] The upper inlet 13 of the housing 10 is connected to the tangential separation device 1 , and the tangential separation device 1 has a tangential inlet 15 thereon. The water replenishing device 8 is connected outside the housing 10 and at the water accumulation area 9 at the bottom of the housing (through the first pipe 11 ). The circulating spraying device 4 is connected outside the housing 10 and between the water accumulation area 9 at the bottom of the housing and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com