Pry plate for lighter

A lighter and skid technology, which is applied in the directions of combustion ignition, igniter with fuel, combustion method, etc., can solve the problems of inability to perform mechanical installation, affecting production efficiency, and only manual installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

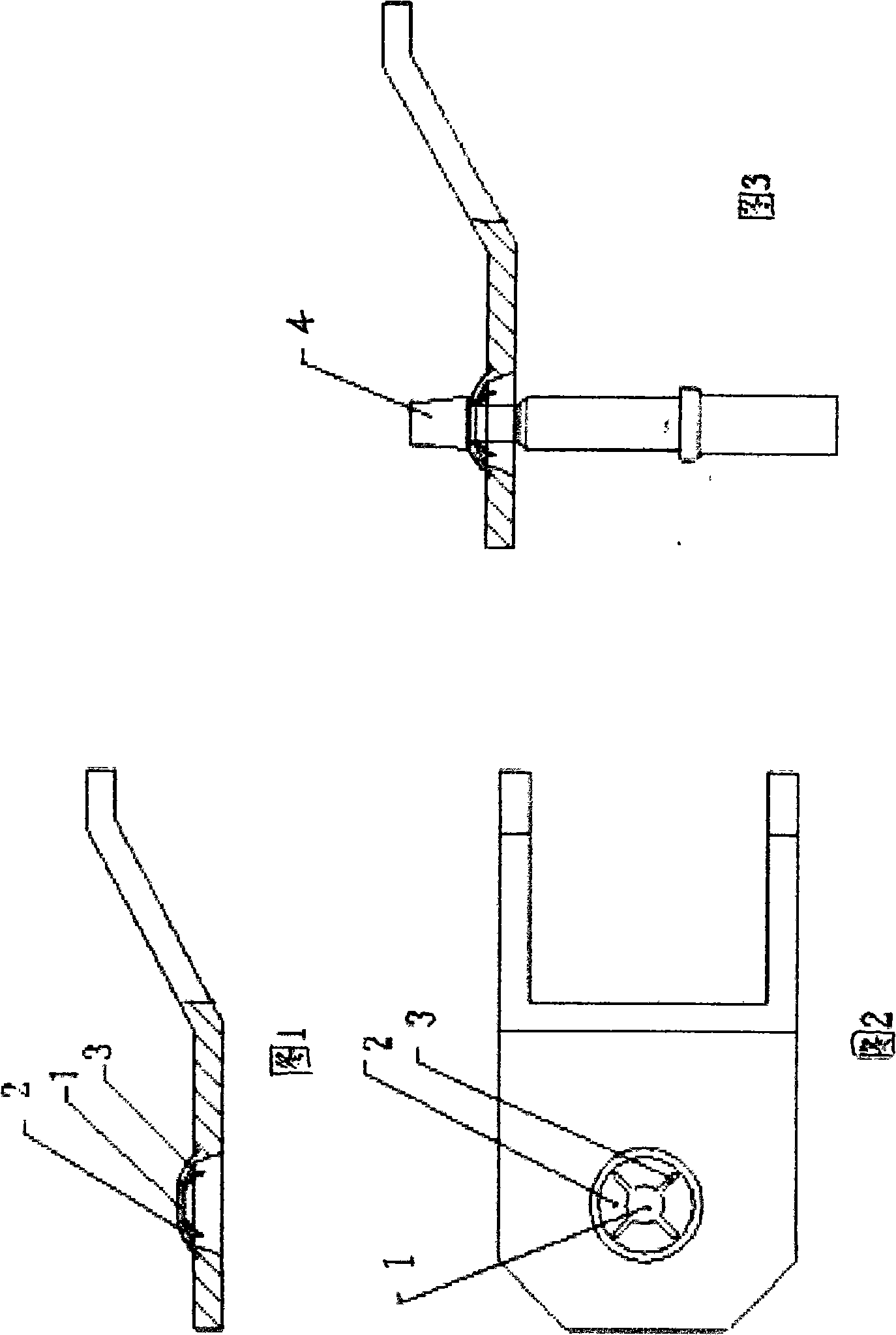

[0008] With reference to accompanying drawing 1,2, make lighter skid plate with metal plate, establish small hole 1 in the skid plate front part, the part 2 around the small hole is made thinner than other parts (concrete thickness should be determined according to material, such as the thickness of other parts 1 mm, the thickness of the part around the small hole is 0.2 mm, the principle is that it has a certain degree of elasticity, it is easy to install on the air needle, and it can ensure sufficient support when lifting the air needle), and it is raised upwards, and with The small hole has at least one opening 3 outwards from the center of the circle.

[0009] The advantages of the present invention are: when installing, align the small hole on the gas needle head of the lighter, and press down, because the part around the small hole is relatively thin, elastic, has an opening, and protrudes upward, so it is easy to insert the gas needle. The small hole at the back is tigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com