Full reflection projection optical system

A technology of projection optical system and total reflection, applied in the field of projection optical system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

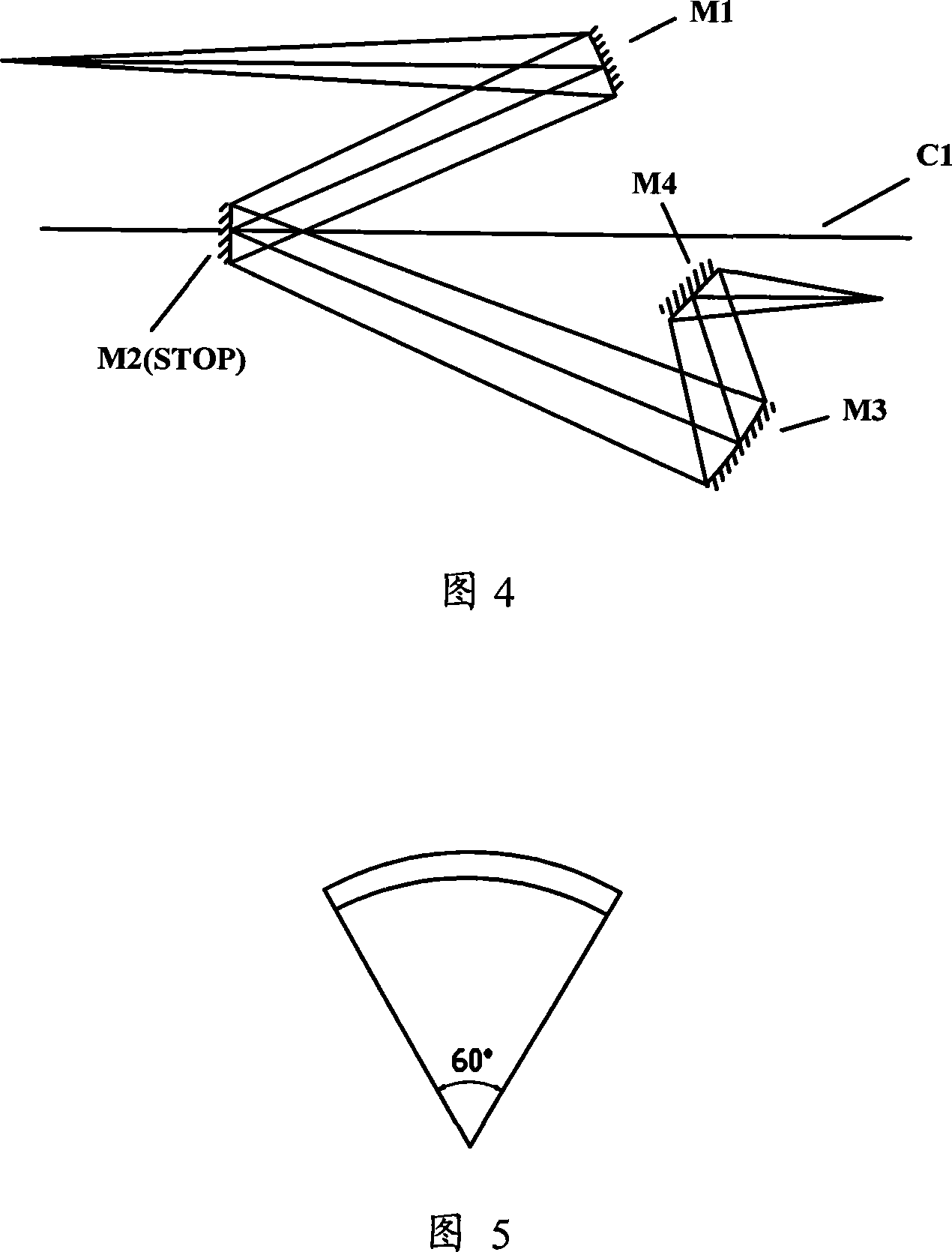

[0023] The invention provides a full reflection projection optical system, such as Figure 4 It is shown that the projection optical system is a four -picked mirror -based projector structure. The main light line and the main light of the square are parallel to the optical axis.The system consists of a mirror group, which includes the first to fourth reflective mirror M1-M4 passed by the light after the object surface.Pore diameter STOP is located on the second reflector M2, about the optical axis C1 rotating symmetry.The third reflective m3 and the fourth reflector M4 are located below the optical axis C1. After the light passes through the third reflector M3, it reaches the fourth reflector M4.The location is located below the optical axis C1.This type of full reflection projection optical system is an inverted image system with an imaging capacity between 1 / 3 and 1 / 4.

[0024] Among them, the first and fourth reflectors M1 and M4 have negative refraction capabilities, and the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com