Automatic balance device of rice transplanter

An automatic balancing and rice transplanting machine technology, which is applied in mechanical control devices, planting methods, transplanting machinery, etc., can solve the problems of not being able to control the whole machine, affecting production efficiency, and floating seedlings, and achieve the effect of avoiding inconsistent depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

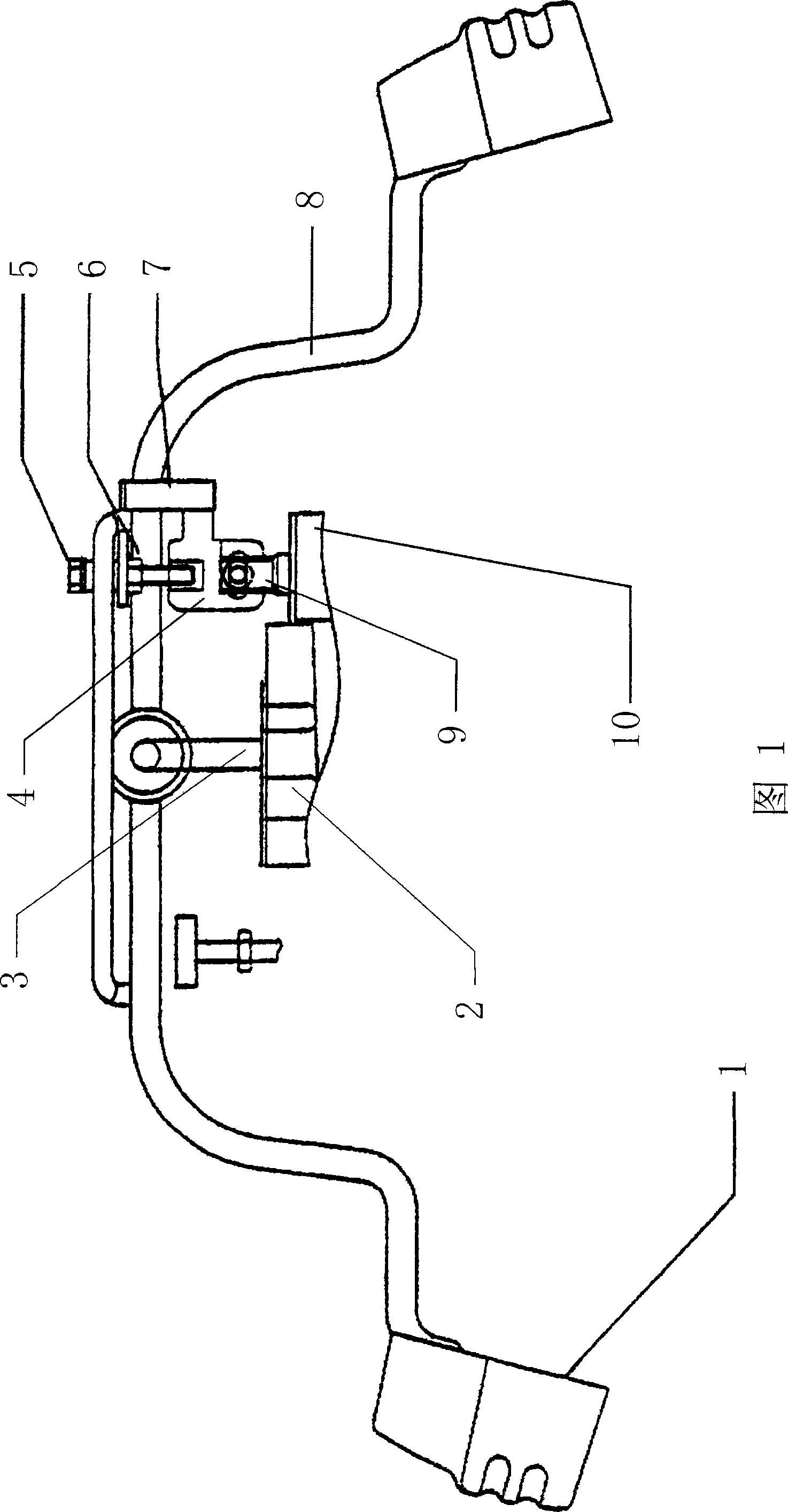

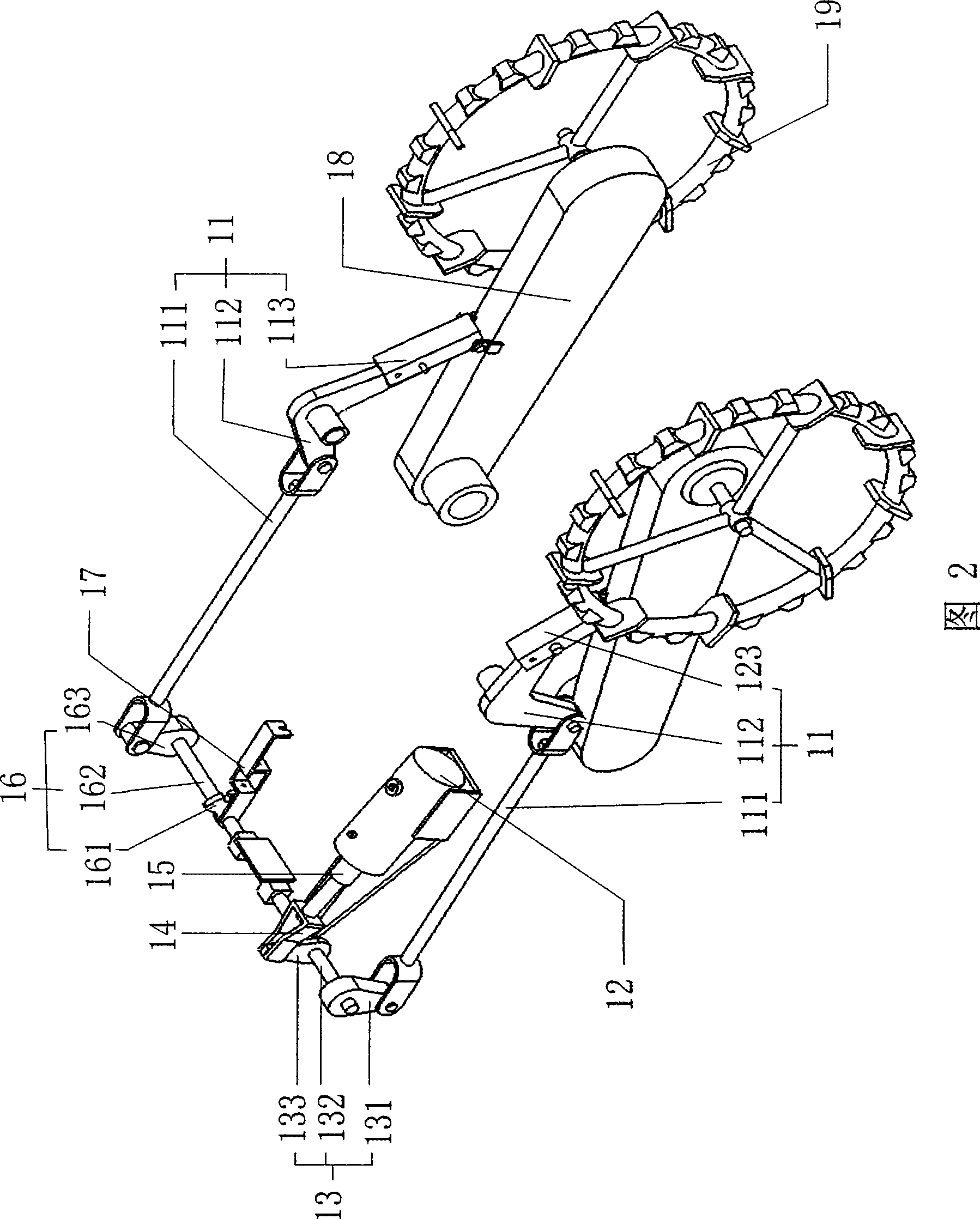

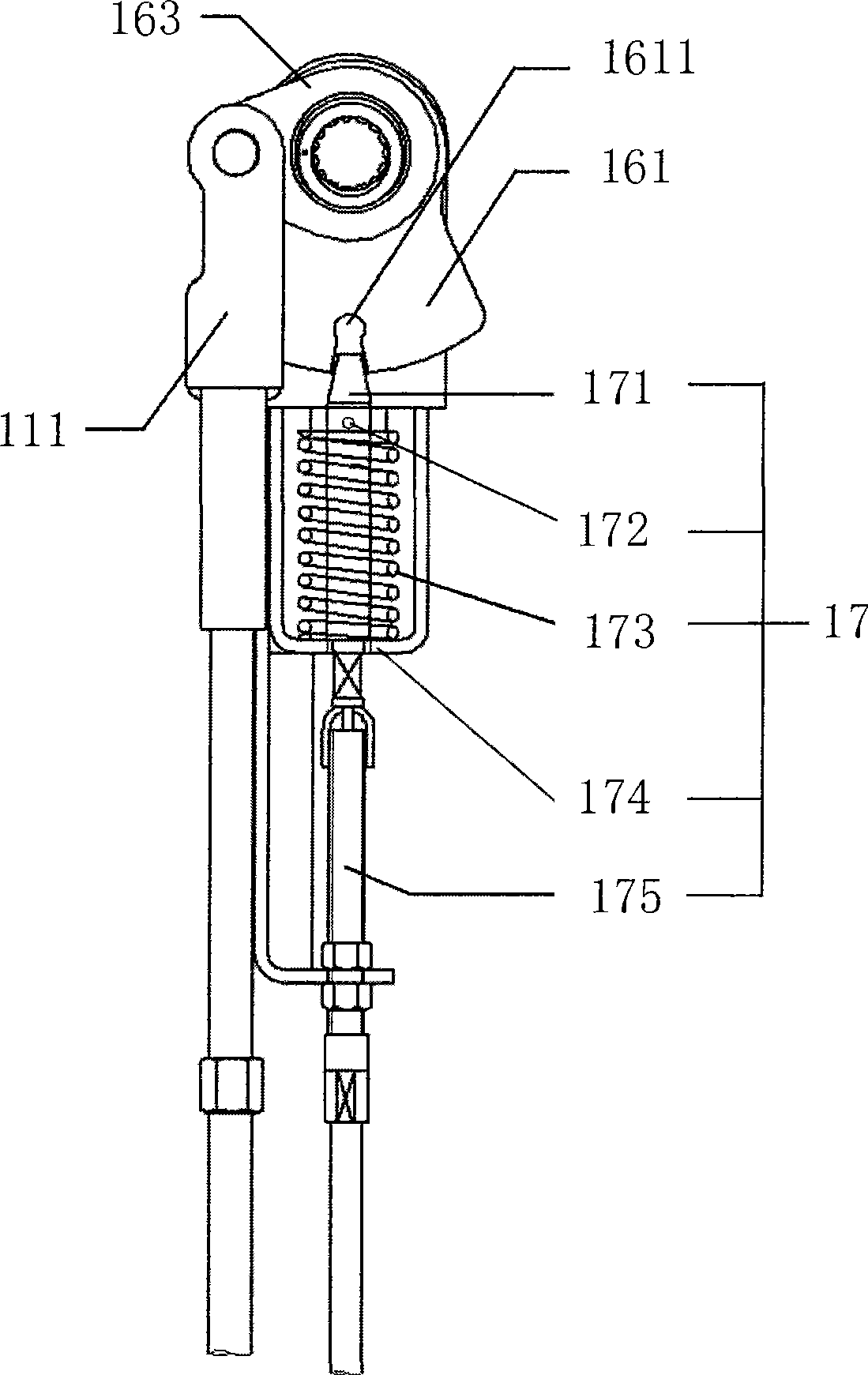

[0014] An automatic balancing device for a rice transplanter according to the present invention not only has the function of lifting and profiling, but also has the function of horizontal balance on the left and right. structure, as shown in Figure 1, Figure 2 and image 3 As shown, the rice transplanter automatic balancing device of the present invention includes a hydraulic unit 10 provided with a balancing valve core 9, a sensor support 2, a sensor assembly installed on the sensor support 2 and a balancer assembly controlled by the hydraulic unit 10, The balancer assembly is fixed on the frame through the seat body, and the sensor support 2 and the hydraulic unit 10 can be installed on the rice transplanter frame. The sensor assembly includes a pole 3 and a lever 8 connected to the pole 3. The two ends of the lever 8 are provided with a sensor weight 1. The arm body of the lever 8 is provided with a linkage mechanism connected with the balance valve core 9 of the hydraulic u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com