Processing method of stamping wheel core

A processing method and wheel core technology, applied in the field of wheel core processing, can solve the problems of heavy wheel core weight, high processing difficulty, poor wheel core strength, etc., and achieve the effect of reducing production cycle, low production cost and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

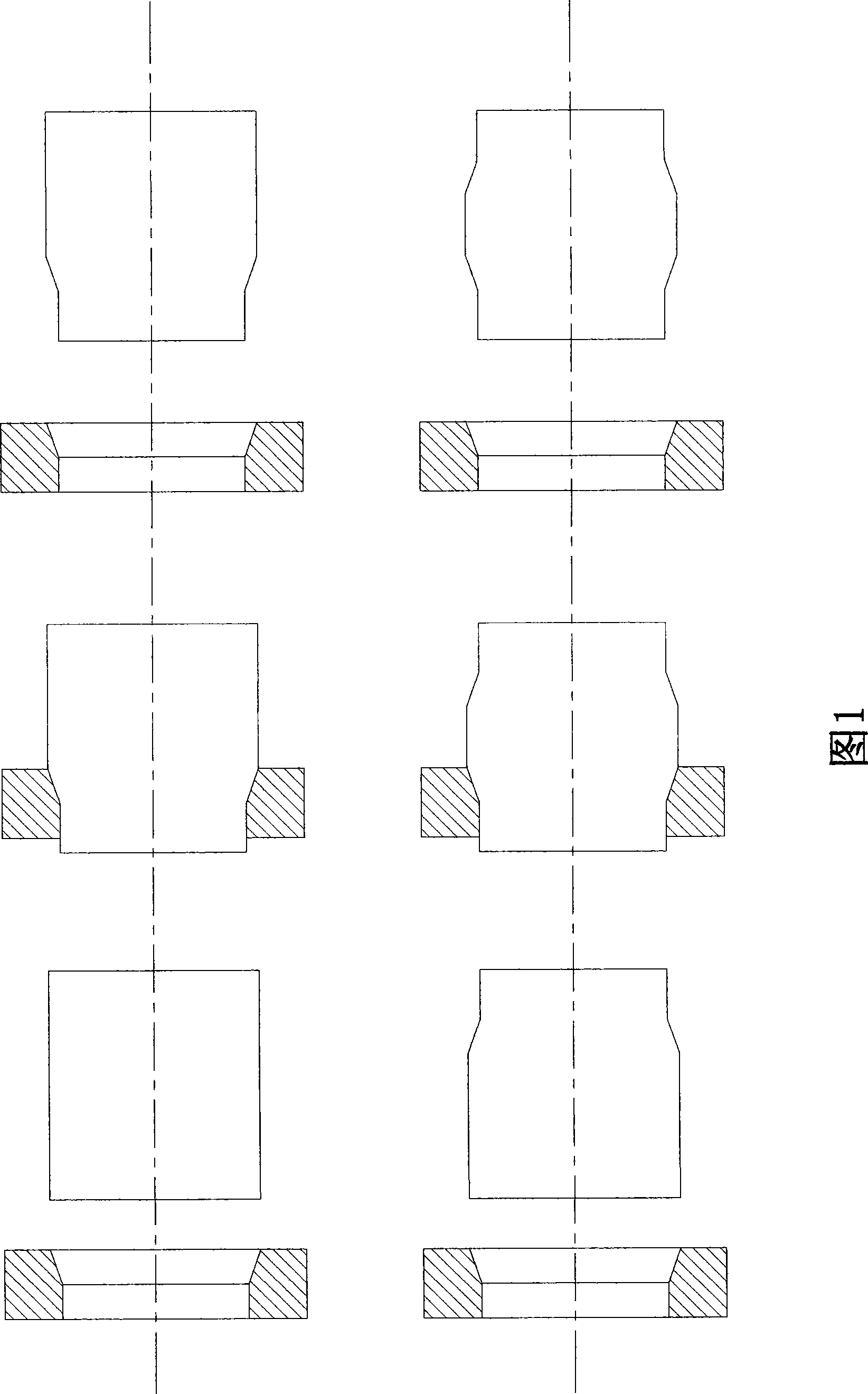

[0013] A method for processing a stamped wheel core according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0014] As shown in accompanying drawing 1, a kind of processing method of stamping wheel core comprises the following steps:

[0015] A. Put the metal pipe 1 into the mold 2, and shrink one end of it by stamping;

[0016] B. Process the other end of the metal pipe 1 according to the method in step A to form it symmetrically with the other end.

[0017] The mold 2 is a hollow tubular design with an inner diameter ranging from large to small.

[0018] The mold is a cold pressure mold or a hot pressure mold.

[0019] The embodiments described above are only one of the more preferred specific implementations of the present invention, and the usual changes and replacements performed by those skilled in the art within the scope of the technical solutions of the present invention should be in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com