Centrifugal ball type braking device for vertical shaft type windmill

A braking device, vertical shaft technology, applied in wind turbines, control of wind turbines, wind turbines at right angles to the wind direction, etc. The effect of easy operation, cost saving and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

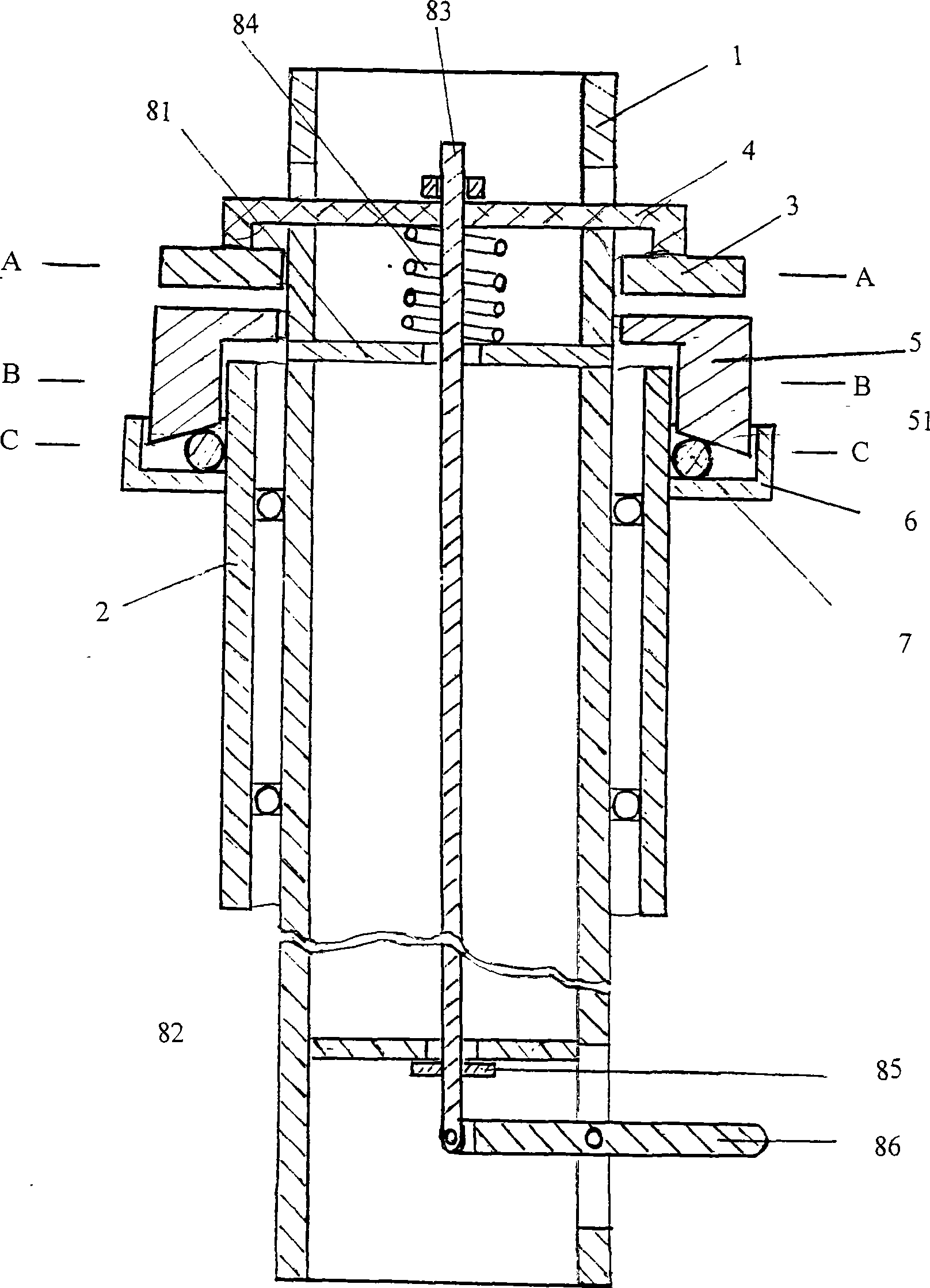

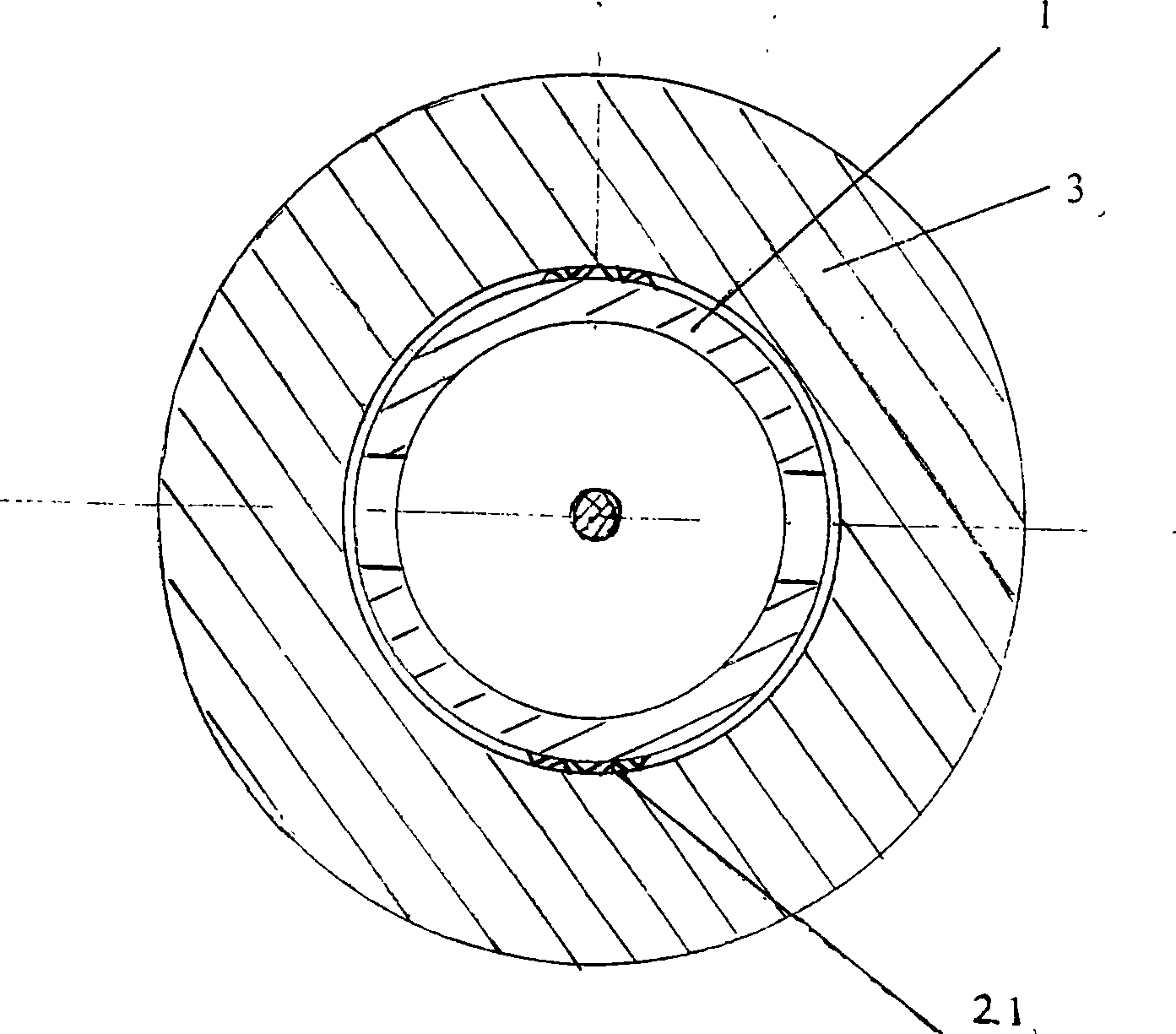

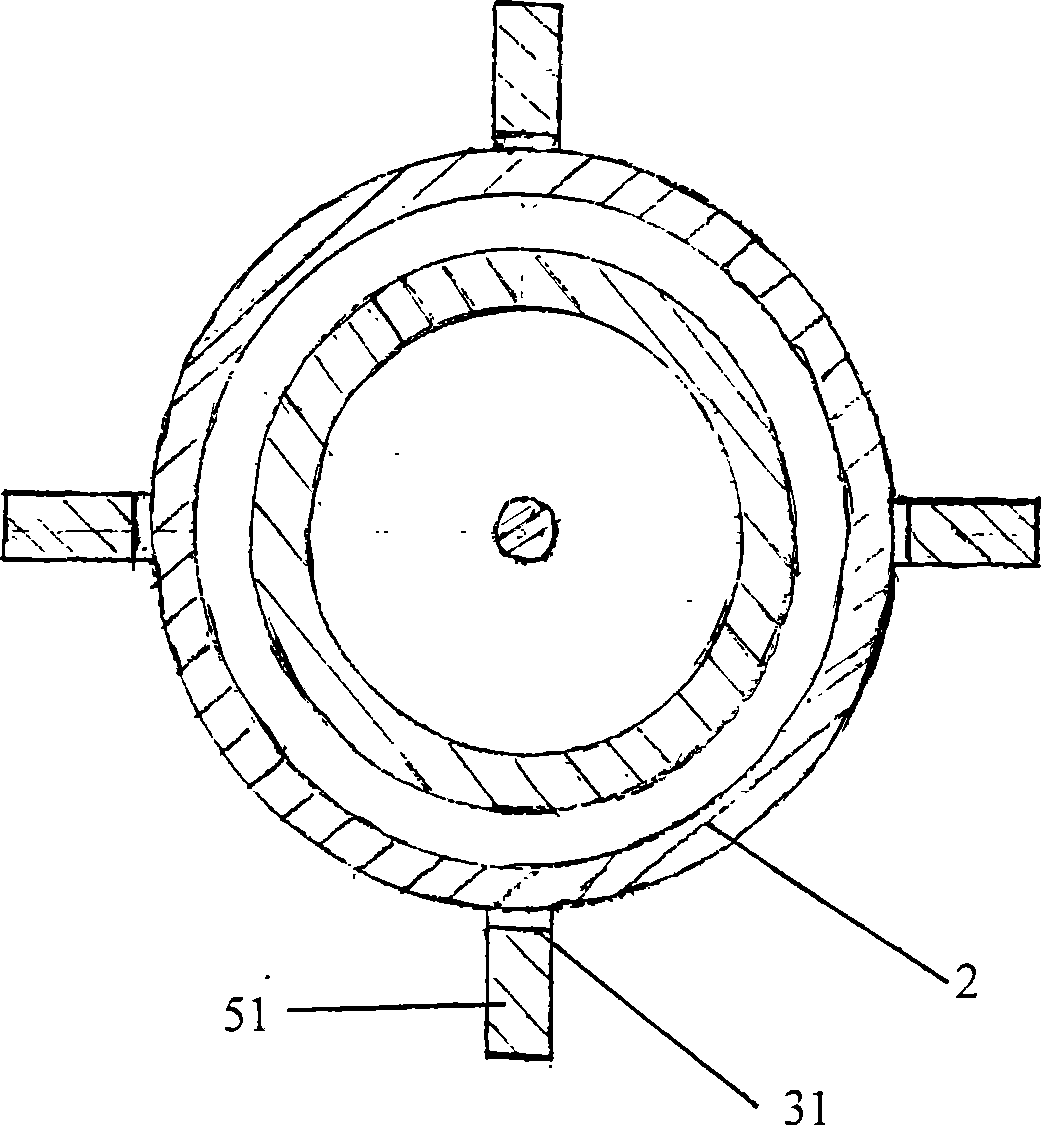

[0018] The structure of the centrifugal ball braking device of the wind power generator in this embodiment is as follows: figure 1 As shown, the device includes a hollow inner shaft 1, a shaft sleeve 2, an upper brake disc 3, a connecting rod 4, a lower brake disc 5, a centrifugal ball rolling groove 5, and a centrifugal ball 6; the shaft sleeve 2 is set on the hollow inner shaft 1, the shaft sleeve 2 and the hollow inner shaft 1 are connected by bearings; the longitudinal section of the upper brake disc 3 with a central through hole is flat and rectangular, and the upper brake disc 3 is set outside the hollow inner shaft 1 , the inner side wall of the upper brake disc 3 and the outer wall of the hollow inner shaft 1 are connected by a key; The shaft 1 has a through hole, and the lower end surface of the longitudinal rod is fixedly connected with the upper bottom surface of the upper brake disc 3; It is composed of at least two legs 51 that are distributed symmetrically and e...

Embodiment 2

[0024] The structure of the wind power generator centrifugal ball type hand brake device of this embodiment is as follows: figure 1 As shown, the hand brake is placed in the hollow inner shaft 1, and the hand brake includes upper and lower positioning supports 81, 82, a transmission connecting rod 83, a return spring 84, a limit ring 85, and a brake handle 86; the upper and lower positioning supports 81, 82 are respectively fixed on the upper and lower ends of the hollow inner shaft 1. There are holes in the center of the upper and lower positioning supports 81, 82. The transmission connecting rod 83 passes through the holes in the centers of the upper and lower positioning supports 81, 82. The transmission connecting rod 83 The upper end is fixed on the connecting rod 4 of the upper brake disc 3, the lower end of the transmission connecting rod 83 is fixed with a limit ring 85, and the limit ring 85 is pushed against the lower positioning support 82. The connection of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com