High-voltage capacitor having rectifying apparatus

A technology of high-voltage capacitors and rectifier devices, applied in the field of electronics, can solve the problems of diode breakdown, low diode withstand voltage strength, and short diode service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

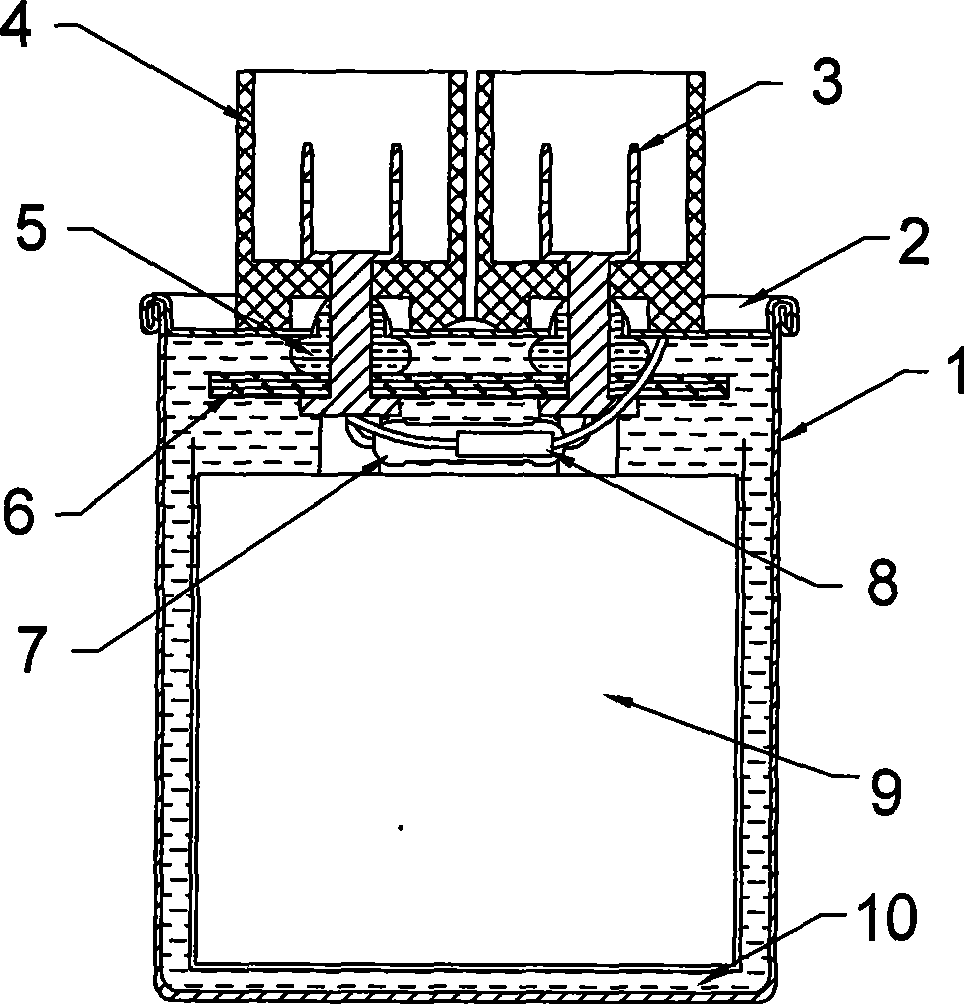

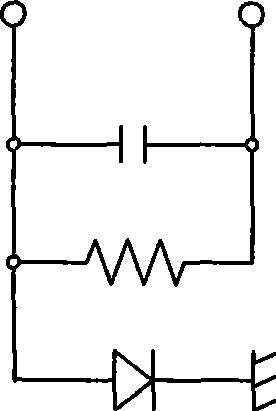

[0012] Such as figure 1 A high-voltage capacitor with a rectifying device is shown, which includes a shell 1 and a soldering piece 3, the shell 1 is sealed and connected to the cover 2, and the inner cavity of the shell 1 is provided with a capacitor core 9, and the capacitor core 9. Use capacitor paper and polypropylene film as the insulating medium, and two sheets of aluminum foil as electrodes. The two electrodes are respectively welded to one end of the two soldering pieces 3, and a discharge resistor 7 is arranged between the two electrodes. The discharge resistor 7 The two ends are respectively welded to two electrodes, the other end of the soldering piece 3 extends out of the cover 2, a silicone pad 5 is provided between the welding piece 3 and the cover 2, and the welding piece 3 extends out of the periphery of one end of the cover 2 An insulating base 4 is provided, and it also includes a diode 8 placed in the inner cavity of the housing 1. One end of the diode 8 is w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com