Elevator and elevator brake

A technology of elevator brakes and brakes, applied in transportation and packaging, elevators, hoisting devices, etc., can solve the problems of elevator car deceleration, endangering passenger safety, etc., and achieve the effect of reliable operation, strong and credible structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

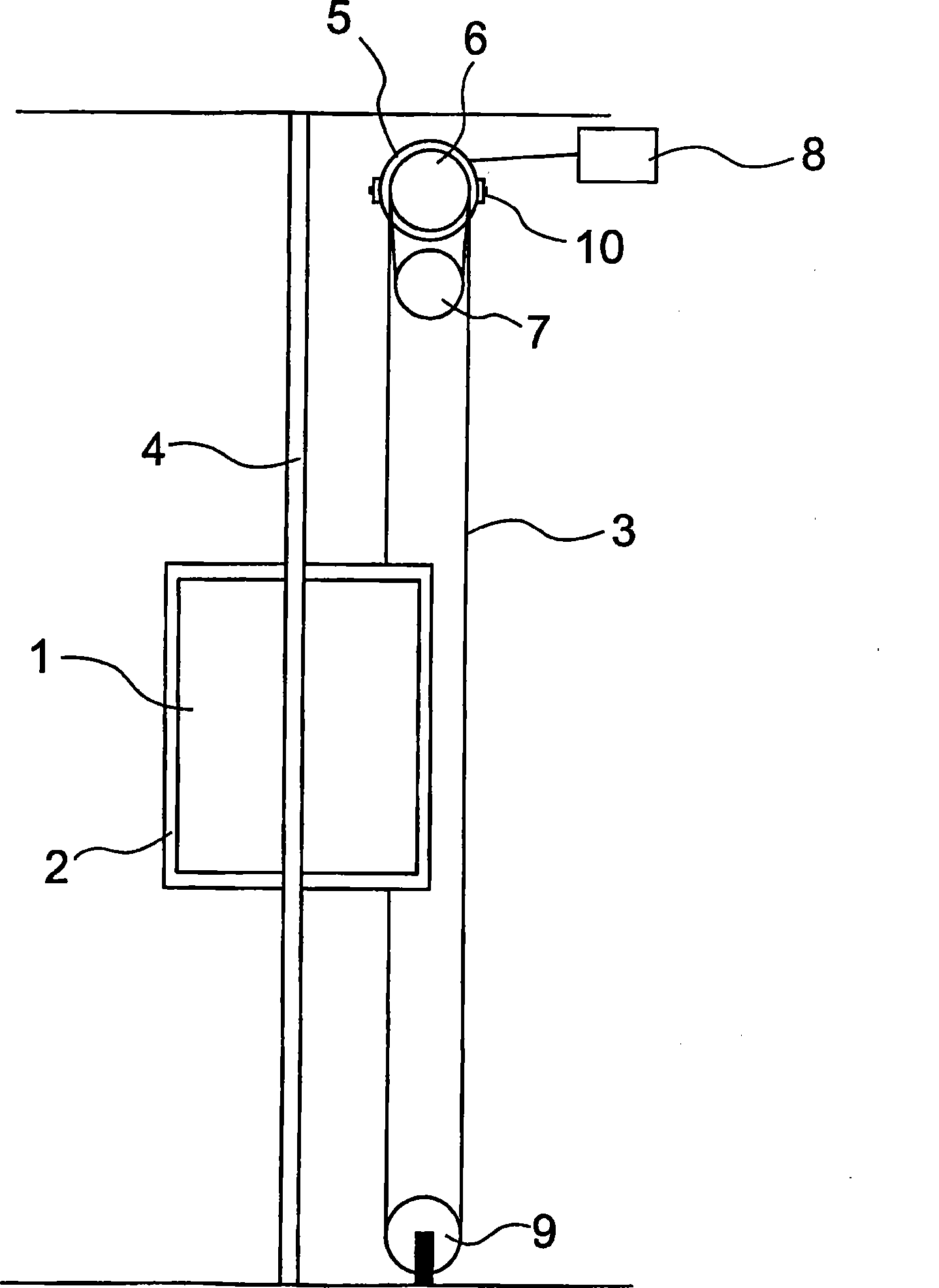

[0011] figure 1 Represents a schematic and simplified side view of a traction sheave elevator without counterweight applicable to the solution of the invention, this elevator comprising at least an elevator traction machine 5 with a traction motor, a traction sheave 6, an elevator control system 8, and the elevator car 1 located in the car hanger 2, which moves in a substantially vertical direction along the guide rail 4 and is suspended on the traction rope 3. The first end of the traction rope 3 is fastened to the top of the car hanger 2, the traction rope 3 is extended from the top of the car hanger 2 and passed around the traction sheave 6, and then passed around the traction machine 5 from below The deflection pulley 1 and then go around the traction sheave 6 again from above, so that it goes around the deflection pulley 9 fixed at the bottom of the elevator shaft from below, and then continues to the bottom of the car hanger 2, the first pulley of the traction rope 3 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com