Bending and molding machine for metal sheet member

A metal plate and forming machine technology, applied in the field of bending and forming equipment, can solve the problems of inability to adjust, poor versatility, wear, etc., and achieve the effect of good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

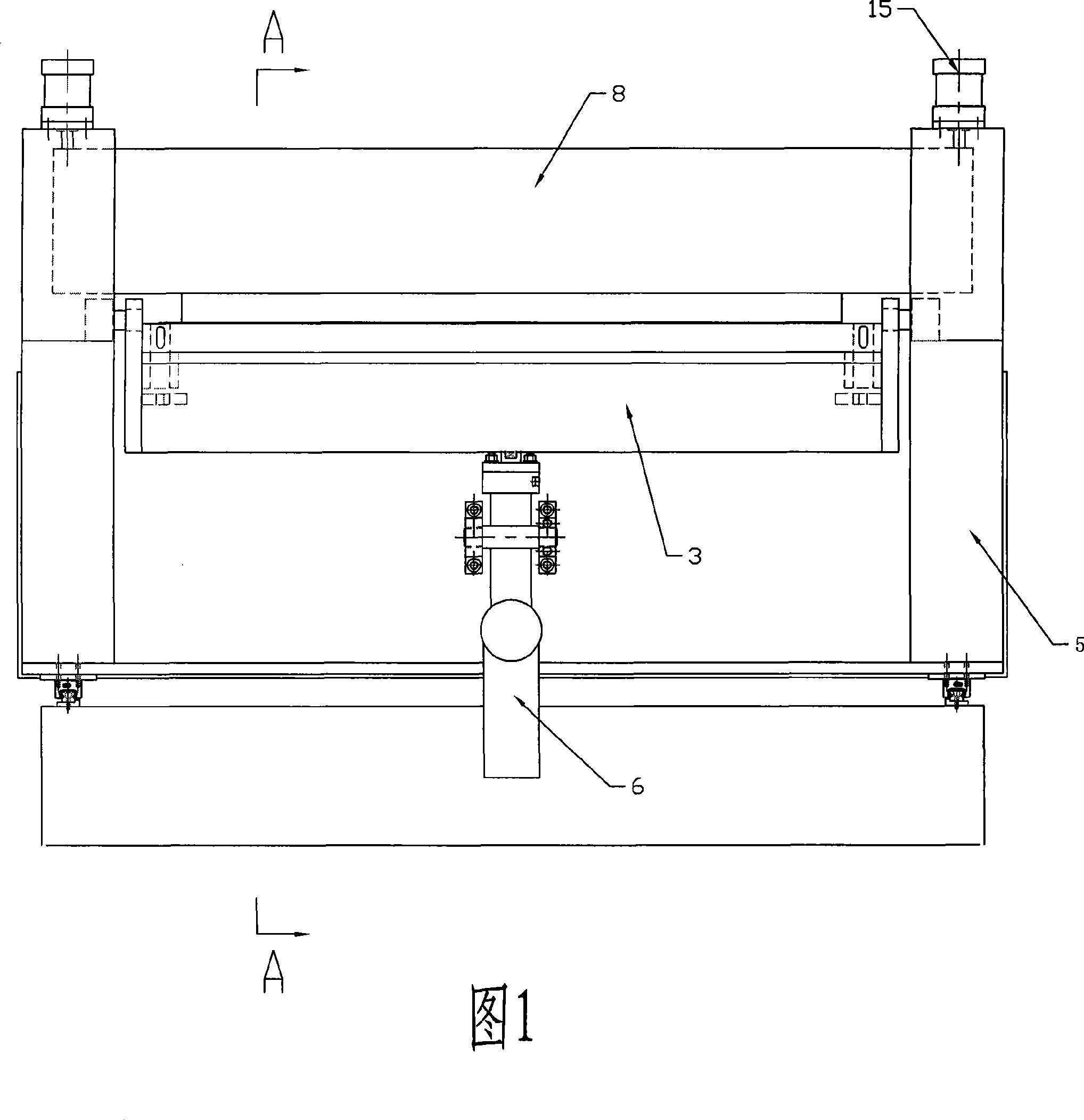

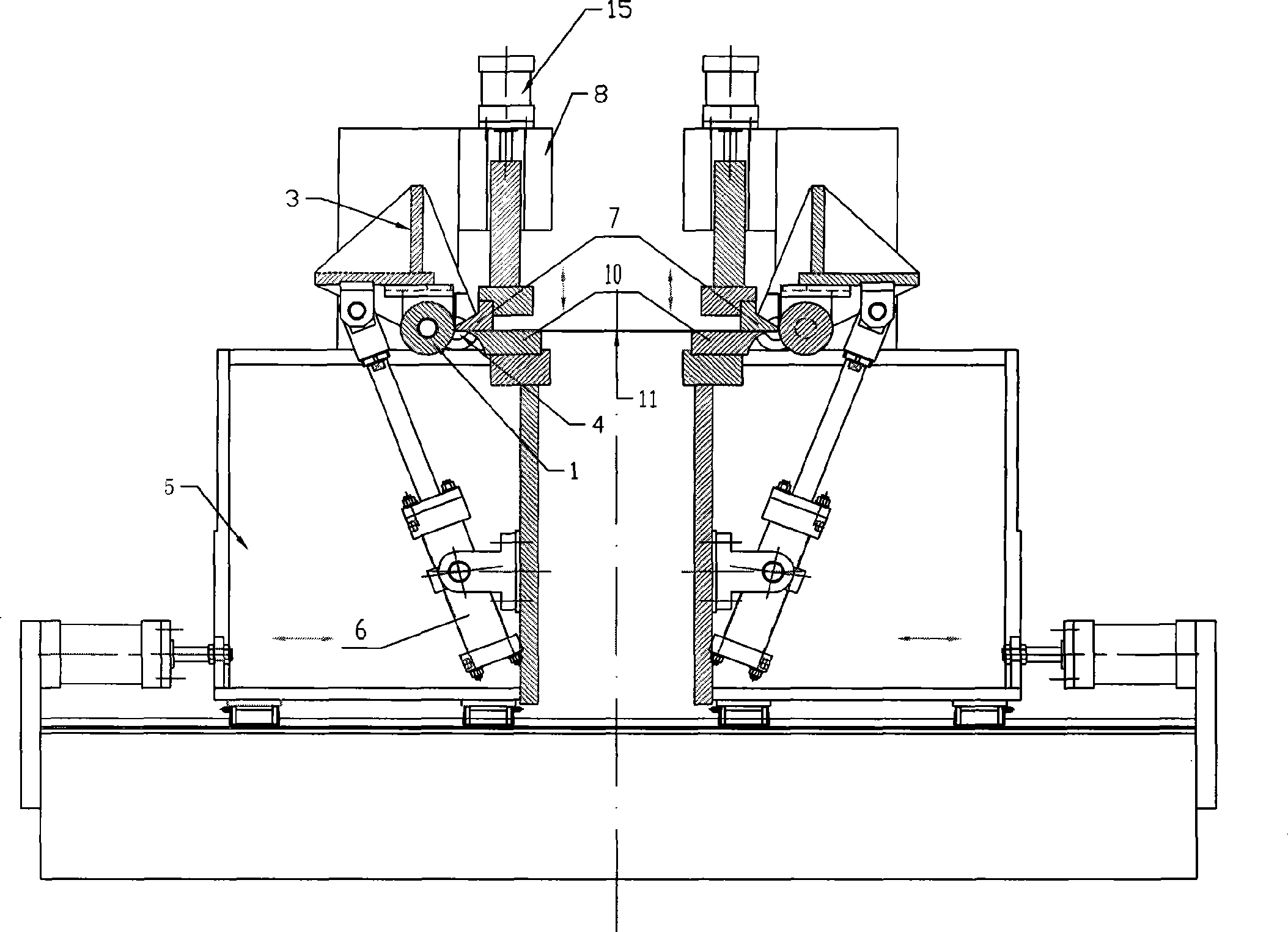

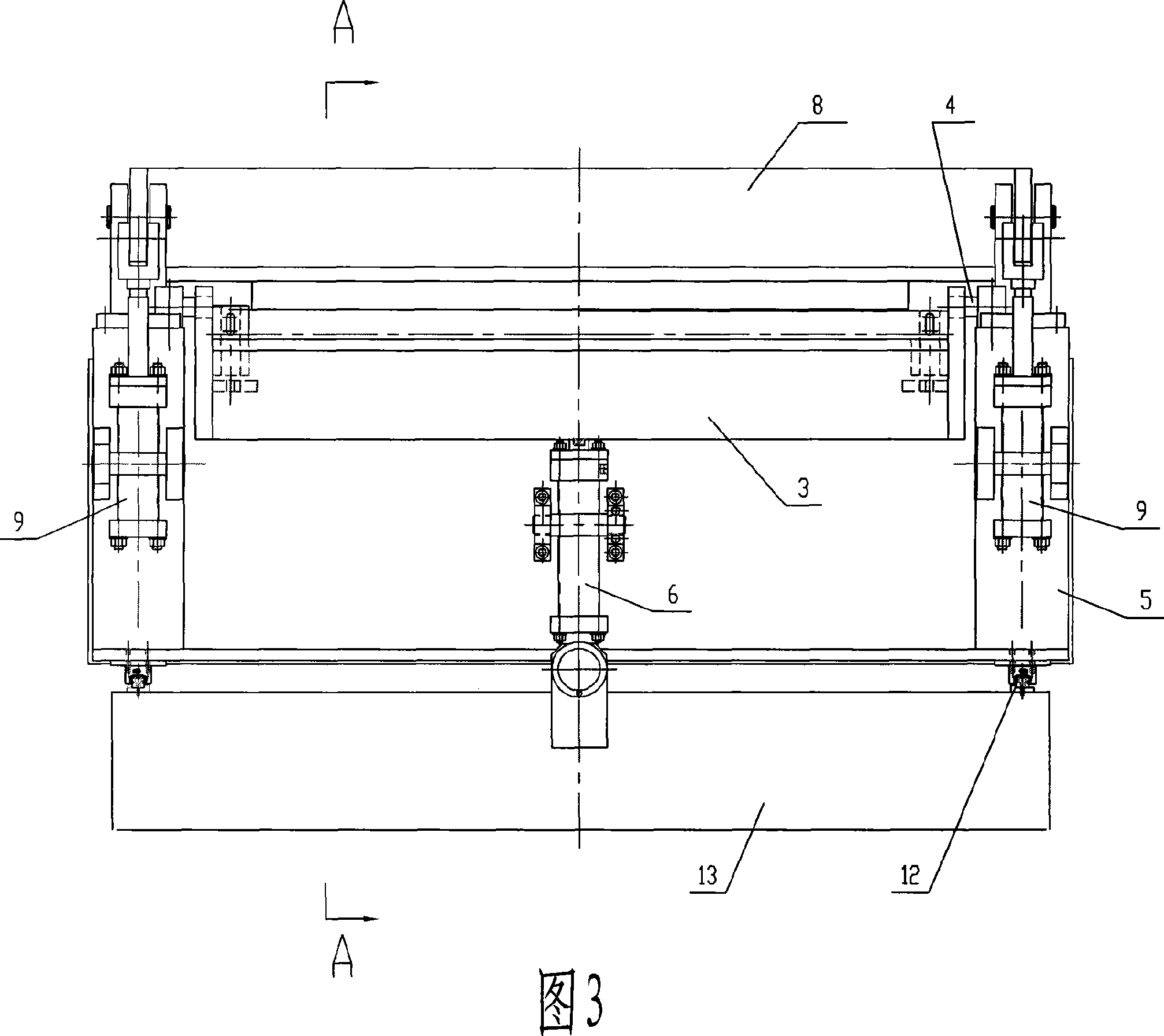

[0011] Figure 1, figure 2 , a metal plate bending forming machine, the support mold 10 for supporting the workpiece 11 is installed on the frame 5, the forming mold 7 is arranged above the support mold 10, the forming mold is installed on the pressure beam 8, and the two ends of the pressure beam pass through The pressure cylinder 15 is connected to the frame above it, and the expansion and contraction of the pressure cylinder can drive the pressure beam to move up and down, thereby driving the molding die 7 to move up and down. There are rotating beams 3 on both sides of the support mold, the rotating beam is hinged with the frame 5 through the fixed axis 4, and can be driven to rotate around the fixed axis by a driving mechanism. The driving mechanism is a pressure cylinder 6, and the cylinder body of the pressure cylinder is hinged with the frame , whose piston rod is hinged to the rotating beam. When the piston rod moves telescopically along the cylinder body, the piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com