Multiheaded cylinder type stone profiling machine

A cylindrical, profiling machine technology, applied to profiling machines. It can solve the problems of poor product shape identity, low production efficiency and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

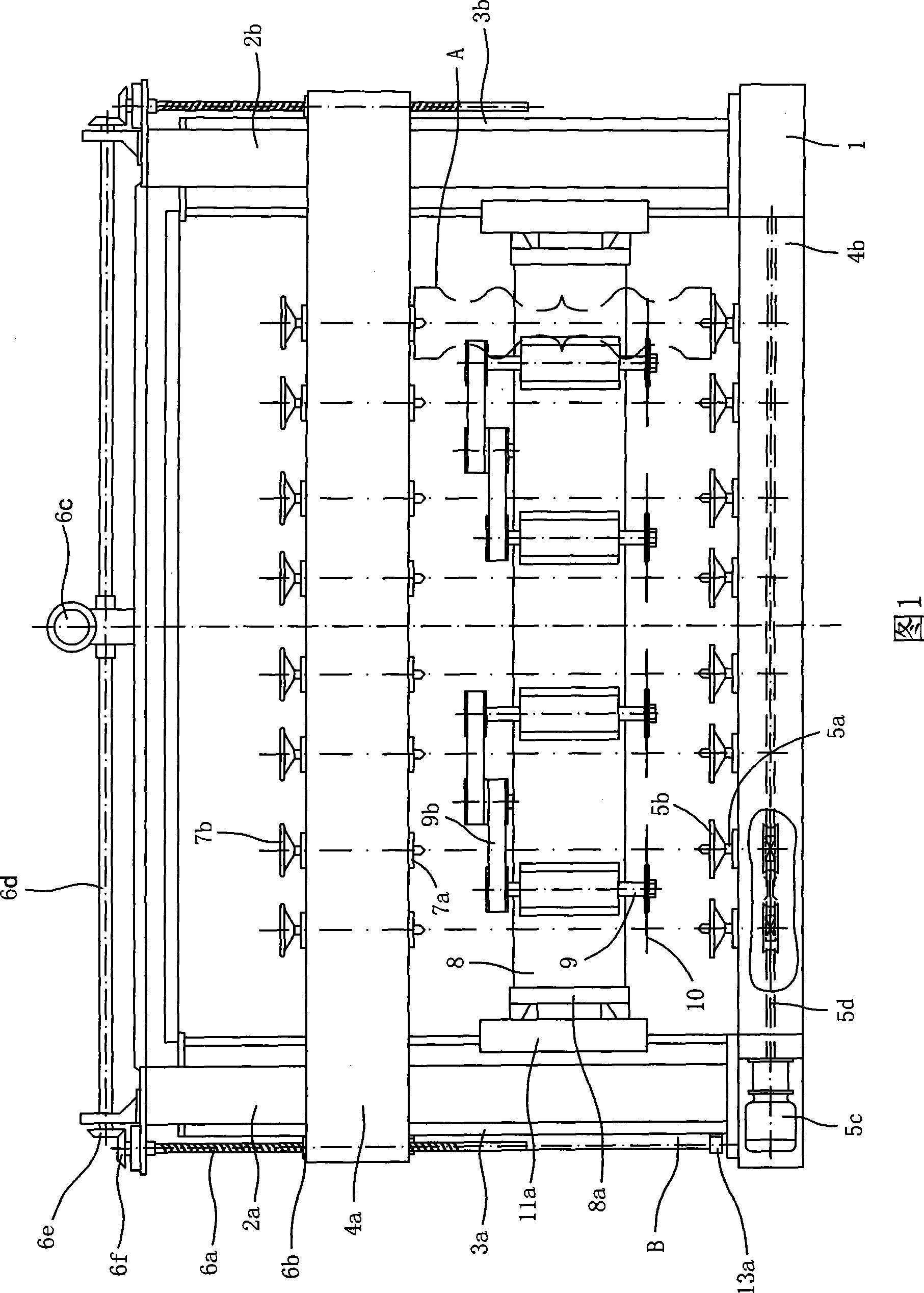

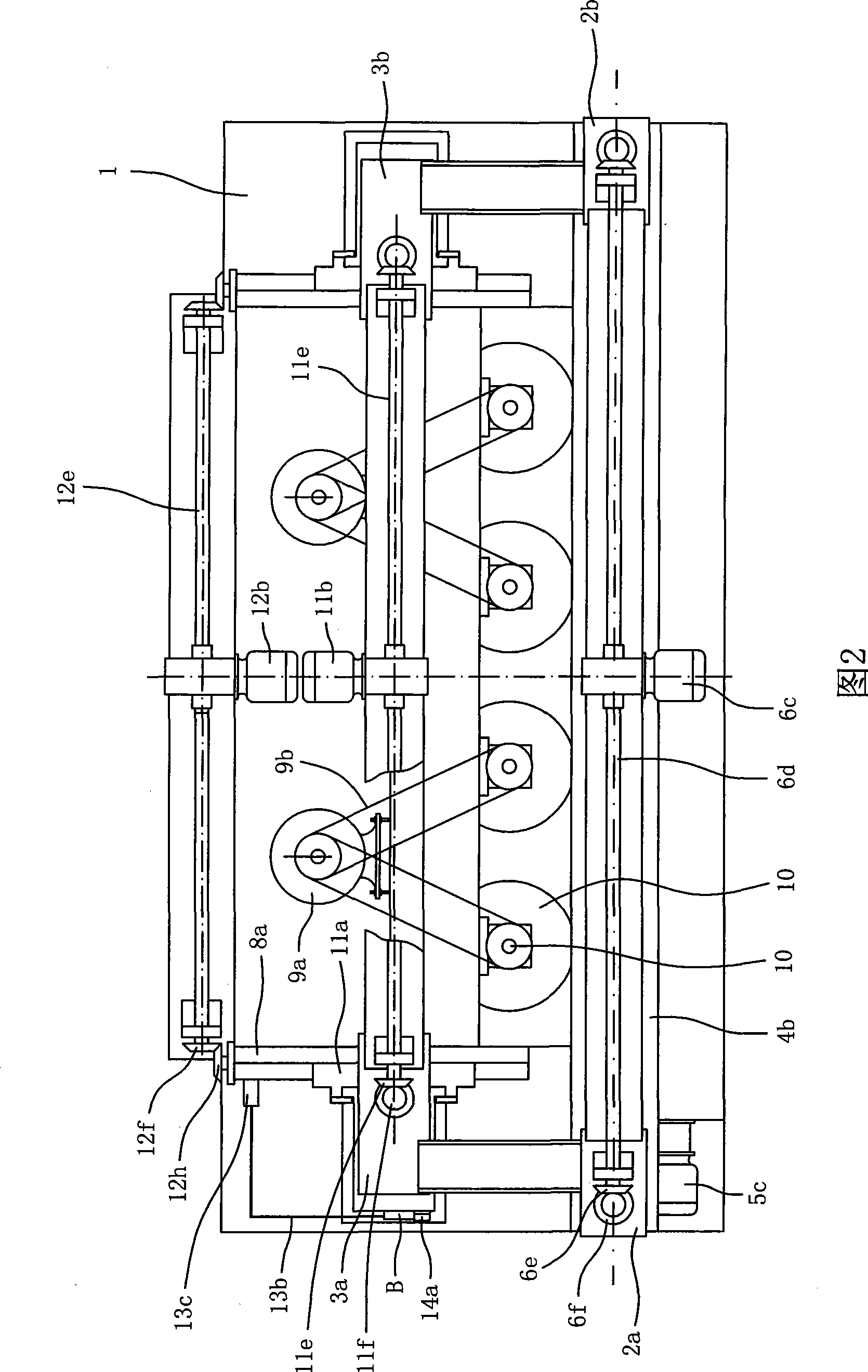

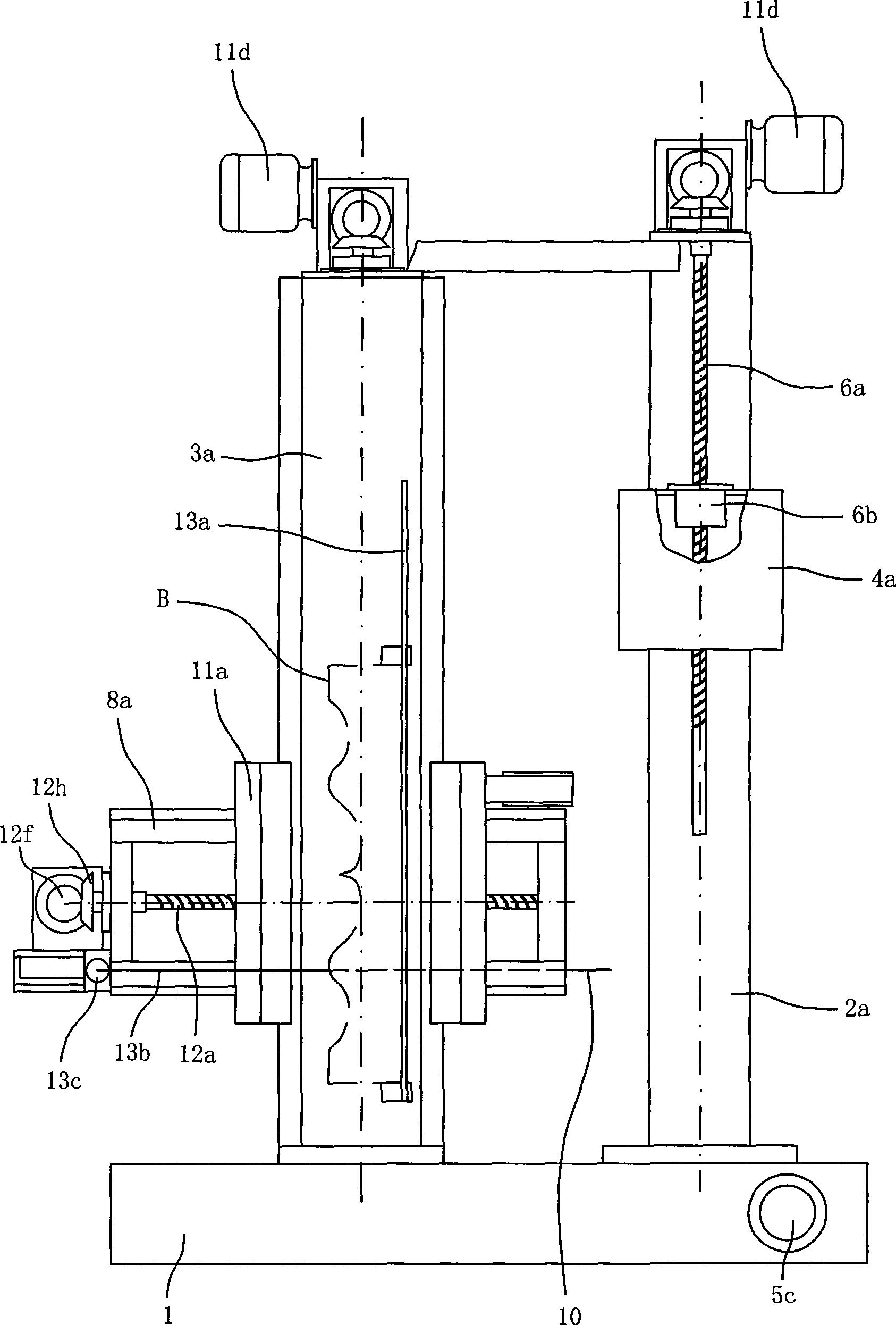

[0014] Refer to Figure 1 to image 3 . The multi-head cylindrical stone profiling machine provided by the invention is composed of the following parts:

[0015] (1) Base 1, a fixed platform directly built on the ground by materials such as concrete.

[0016] (2) uprights, comprise the front and rear uprights that are fixed vertically on the base correspondingly, the front and back uprights respectively comprise left uprights 2a, 3a, right uprights 2b, 3b symmetrically arranged on both sides of the base, four uprights 2a, 3a, The tops of , 2b and 3b are connected with the base 1 to form a square frame with a stable structure after being connected by four connecting beams. The front left and right columns 2a, 2b are cylinders, and the rear left and right columns 3a, 3b are square columns.

[0017] (3) The workpiece clamping mechanism includes upper and lower beams 4a, 4b correspondingly arranged between the front left and right columns 2a, 2b. The workpiece support plate, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com