Air supply system of semiconductor process equipment and its gas flow calibration method

A technology of processing equipment and gas supply system, applied in semiconductor/solid-state device manufacturing, flow control of electrical devices, electrical components, etc., can solve the problems of increasing the cost of semiconductor processing equipment, high value, and long calibration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

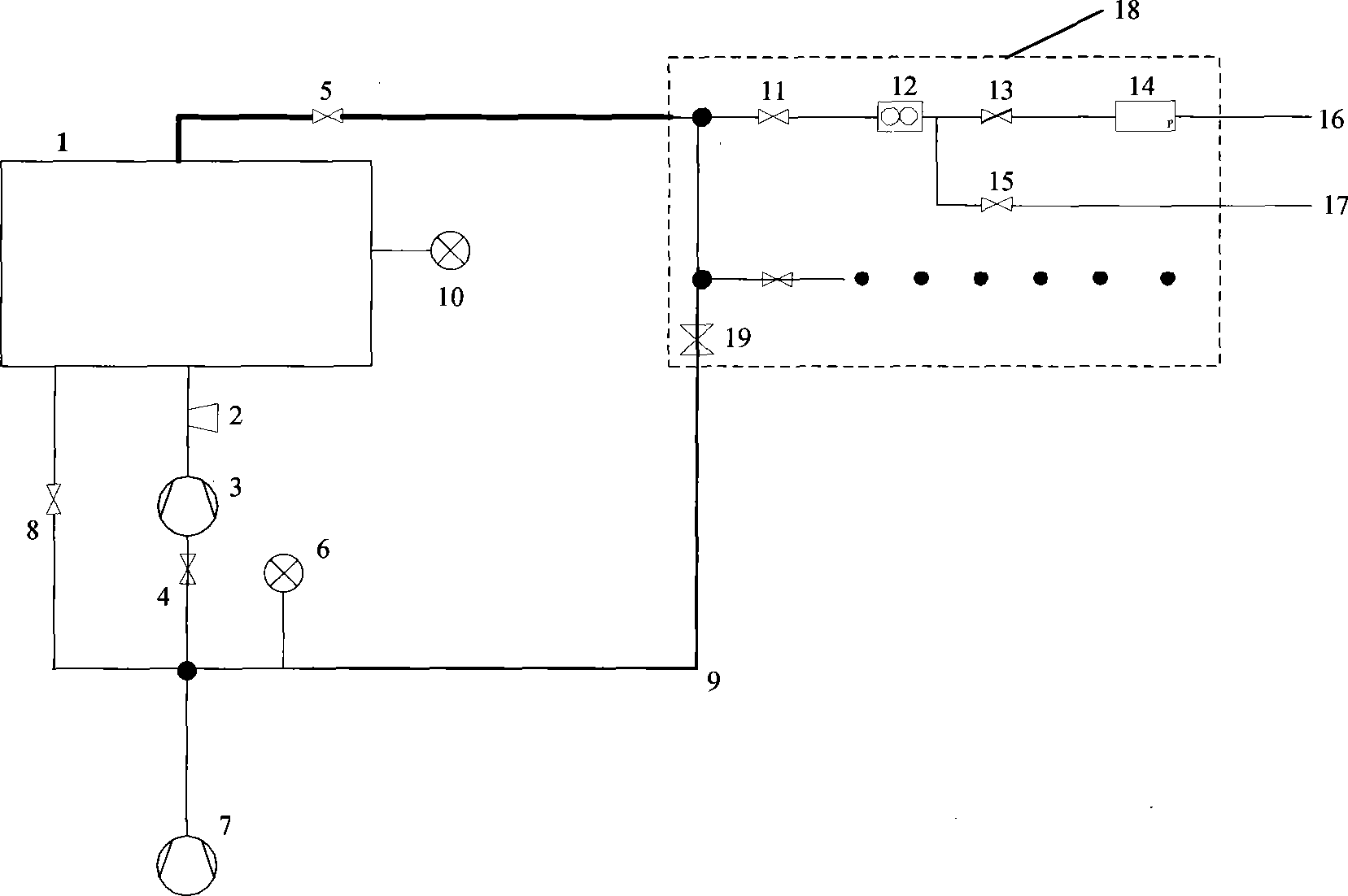

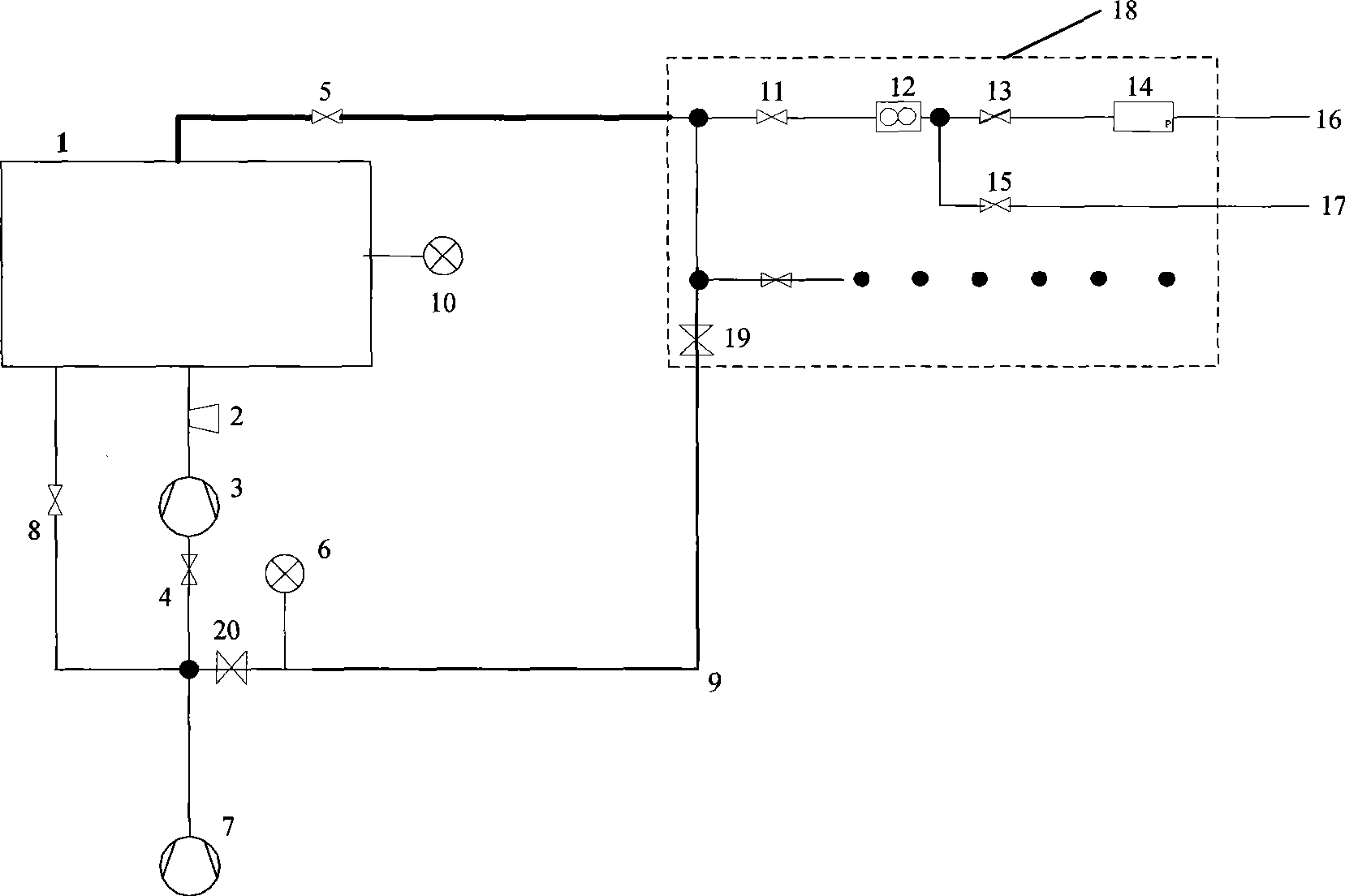

[0021] The specific embodiment of the gas supply system of the semiconductor processing equipment of the present invention, such as figure 2 As shown, a gas circuit box 18 is included for supplying gas to the reaction chamber 1. The gas circuit box 18 is provided with an MFC (mass flow controller) 12, and the gas circuit box 18 is also provided with a gas circuit box for cleaning. The pipeline 9, the gas box cleaning pipeline 9 is provided with a calibration isolation valve 20 . A vacuum gauge 16 is provided on the air box cleaning pipeline 9 between the air box 18 and the calibration isolation valve 20 .

[0022] In this way, the gas circuit box cleaning pipeline 9 between the gas circuit box 18 and the dry pump 7 can be isolated into a closed pipeline by using the calibration isolation valve 20, which can be used as a chamber for gas flow calibration. The gas pressure in the chamber is measured.

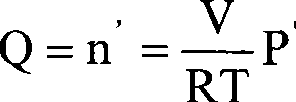

[0023] The method for calibrating the gas flow of the gas supply system of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com