Rotary disc type liquid-filling machine for battery

A liquid injection machine, turntable technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of easy damage to the machine, waste of resources, low work efficiency, etc., to ensure the accuracy of liquid injection and improve work efficiency. , good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

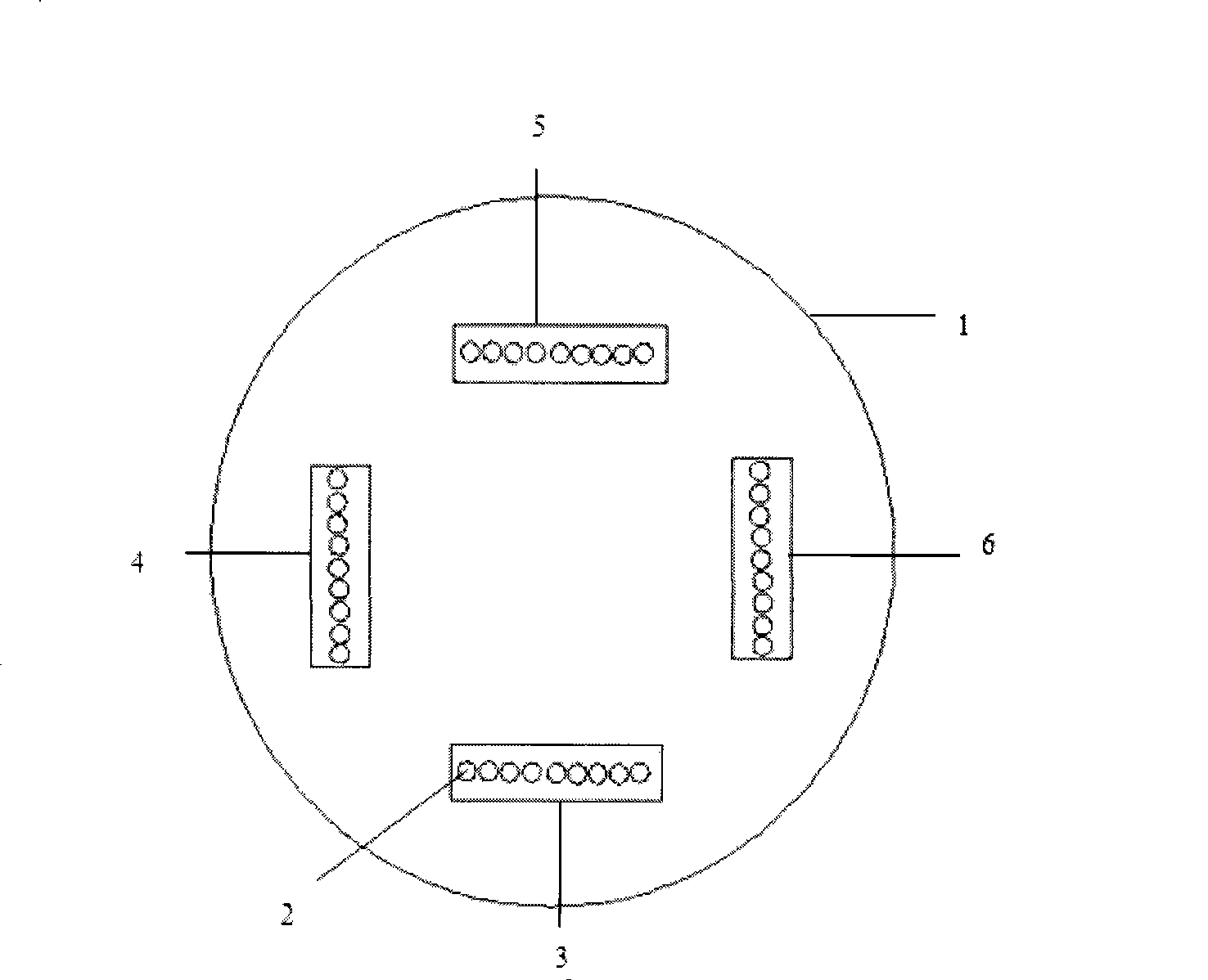

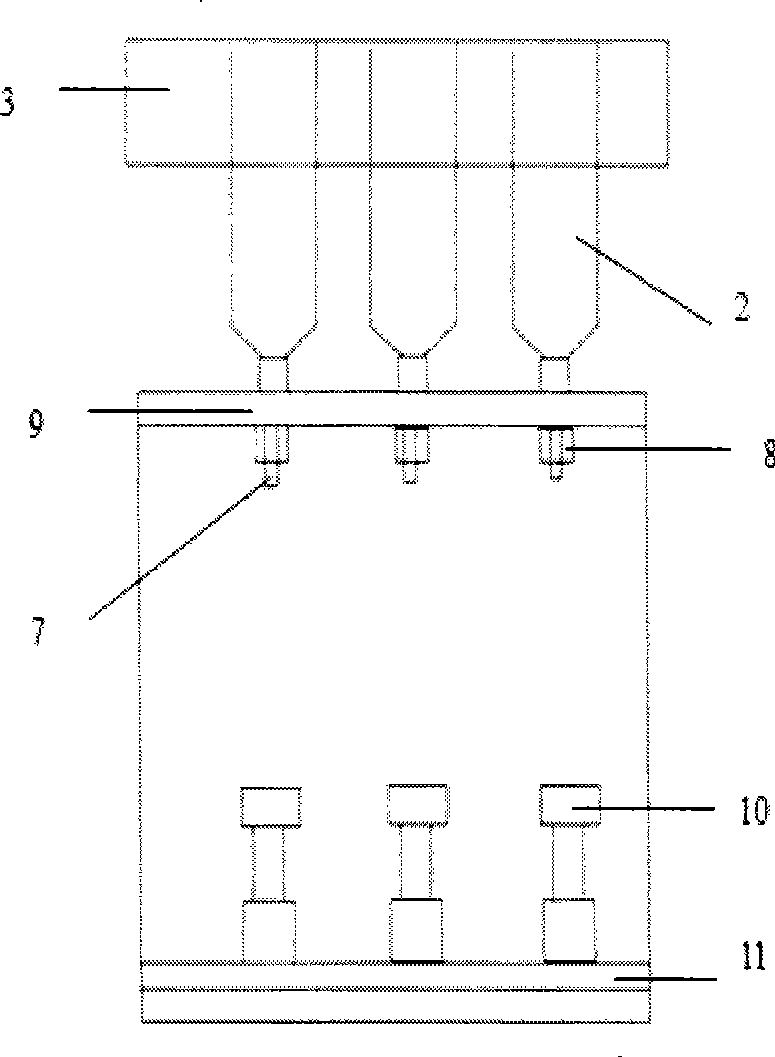

[0015] like figure 1 , figure 2 As shown, the present invention includes a frame, a battery holder, a turntable, a liquid injection device, a vacuum box, a pressing plate, a divider, a vacuum pumping system, a drying gas adding system and an air compression system. It is characterized in that: there are four symmetrically distributed perforations on the turntable 1, the liquid injection device includes a liquid injection cylinder 2, a liquid injection needle 7 and a Haiba pump, and the liquid injection needle 7 is communicated with the liquid injection cylinder 2, and the fixed plate 3 is arranged side by side neatly. A plurality of liquid injection cylinders 2 are fixed, the fixed plate 3 is embedded in the perforation of the turntable 1, the upper part of the battery clamp is provided with a positioning plate 9, a number of liquid injection needles 7 are fixed on the positioning plate 9, and the lower part is a bottom plate 11 and a number of bases 10. There are elastic pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com