Sheller unit of combine

A technology for combine harvesters and threshing devices, which is applied in threshing equipment, agricultural machinery and implements, applications, etc., and can solve the problem that the dynamic balance test of the threshing drum is difficult to do accurately, the accuracy of the dynamic balance test cannot be guaranteed, and the normal operation of the threshing drum is affected. and other problems to achieve the effect of easy removal, reduced vibration and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The threshing device on the combine harvester of the present invention will be further described below in conjunction with accompanying drawing:

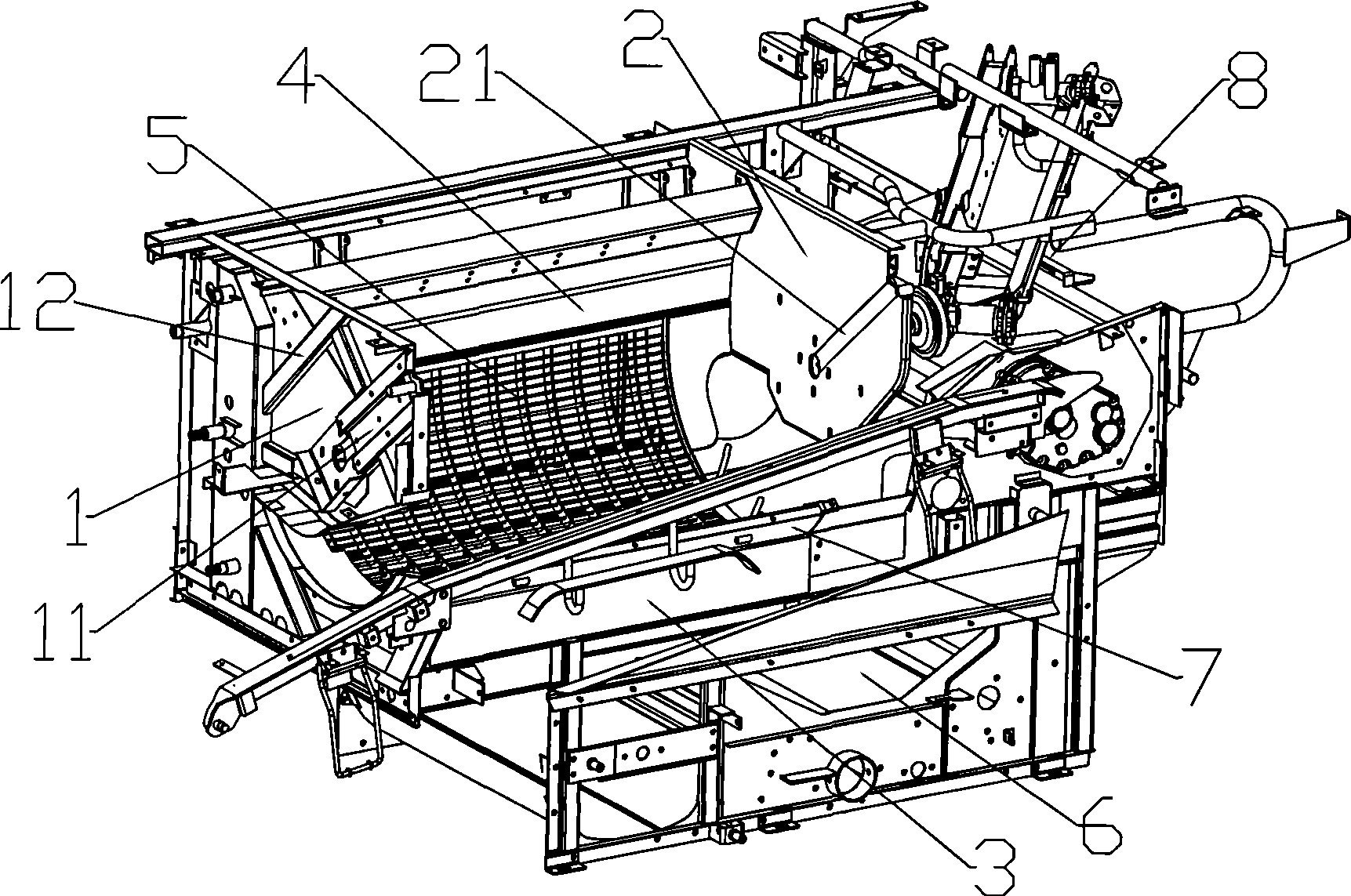

[0015] Such as figure 1 As shown, the threshing device on the combine harvester of the present invention includes a distribution chain and a clamping track, a threshing drum, a threshing chamber, a swinging sorting device and a grain storage box device. The threshing chamber includes a left strong plate 1 and a right strong plate 2. The front strong plate 3, the rear strong plate 4 and the top cover, the threshing drum is installed in the threshing chamber, the arc-shaped filter screen 5 is installed under the threshing drum, and the swing sorting device 6 is installed on the arc-shaped filter screen 5 Below, on the right side of the right strong plate 2, a grass discharge chain device bracket and a grass discharge chain device 8 are installed. The rotating shaft of the threshing drum is directly fixed on the drum, and the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com