Control disk system for elevator

A technology for control panels and elevators, applied in cooling/ventilation/heating transformation, elevators, transportation and packaging, etc., can solve the problems of low cooling efficiency of the second heat source, reduce volume, reduce complexity and cost, and achieve high efficiency The effect of installation flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

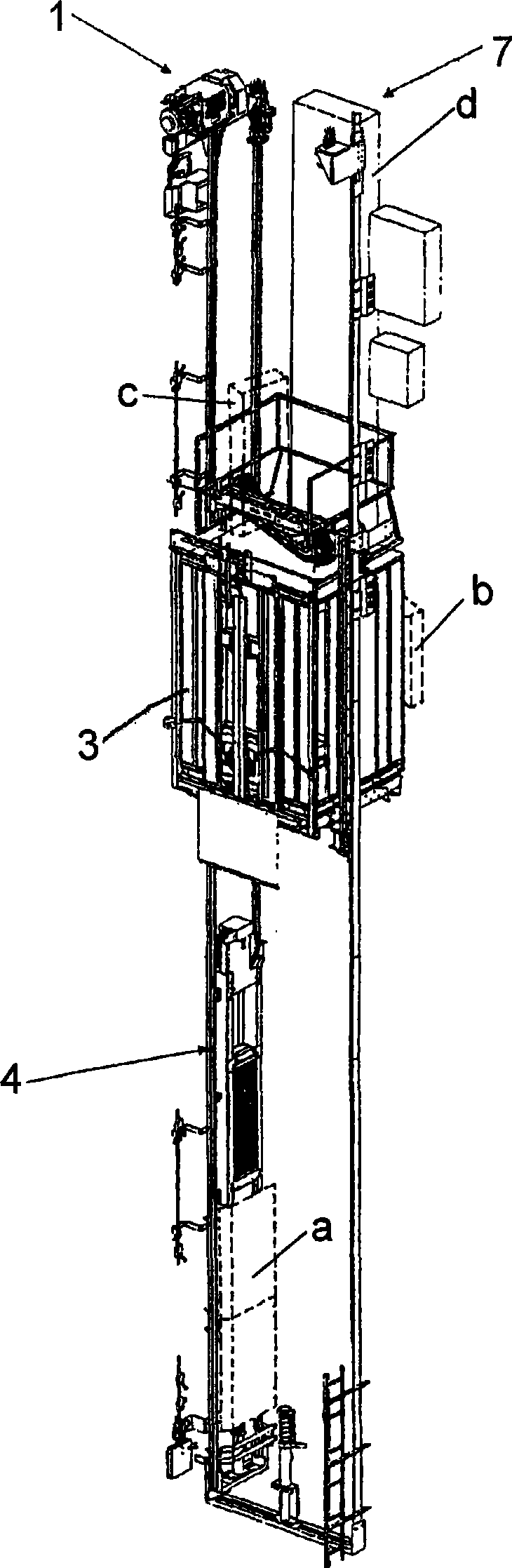

[0021] figure 1 Shows a schematic view of an elevator according to the present invention, as shown in the figure, a traction machine 1 is provided on the top side of the elevator, and the traction machine 1 is connected with a car 3 arranged in the hoistway so as to cooperate with a counterweight 4 The car 3 is raised or lowered to realize the transportation of passengers or goods. In the elevator according to the present invention, the hoisting machine 1 can be arranged in the elevator machine room or in the elevator shaft. Furthermore, the elevator comprises a control panel system 7 via which the hoisting machine 1 and thus the lifting of the elevator car 3 is controlled.

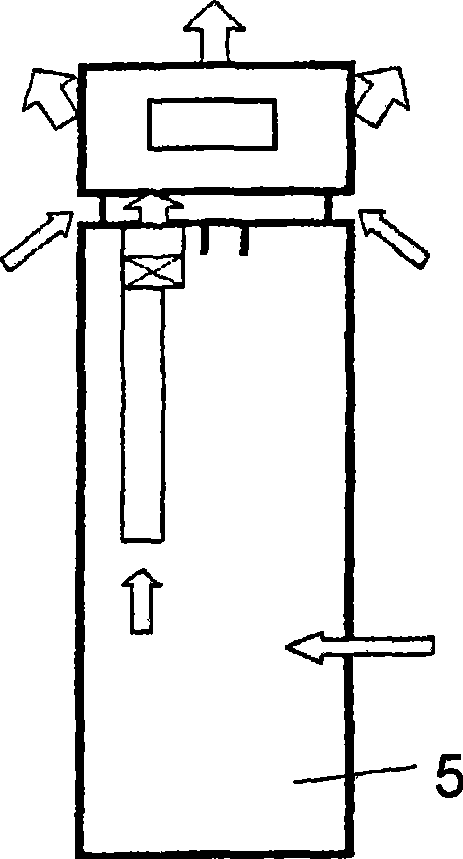

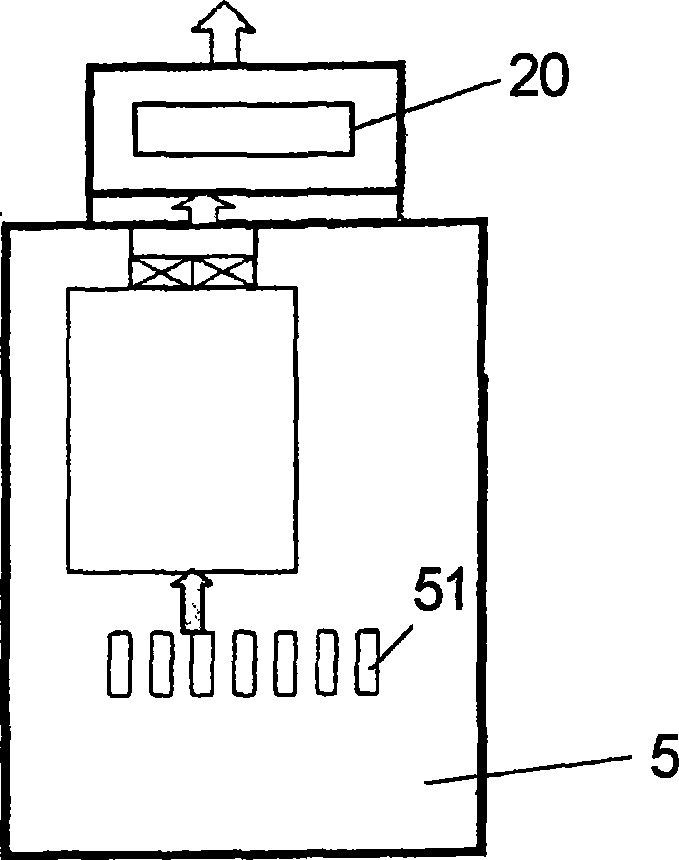

[0022] Figure 2a and 2b A schematic diagram of an elevator control panel system according to the invention is shown, where the arrows show the flow direction of the cooling fluid. In this embodiment the cooling fluid is air from the external environment. Of course, a special cooling fluid supply dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com