Mechanical stepless automatic speed variator

An automatic transmission, stepless technology, applied in the direction of mechanical equipment, transmission devices, belts/chains/gears, etc., can solve the problems that mechanical transmissions cannot meet the actual needs of mechanical transmission variable speed transmission, etc., and achieve the effect of good use and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

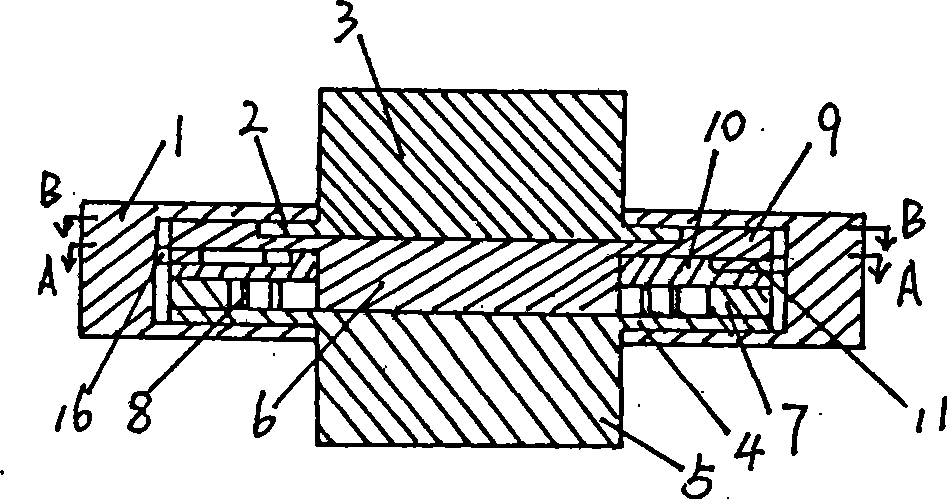

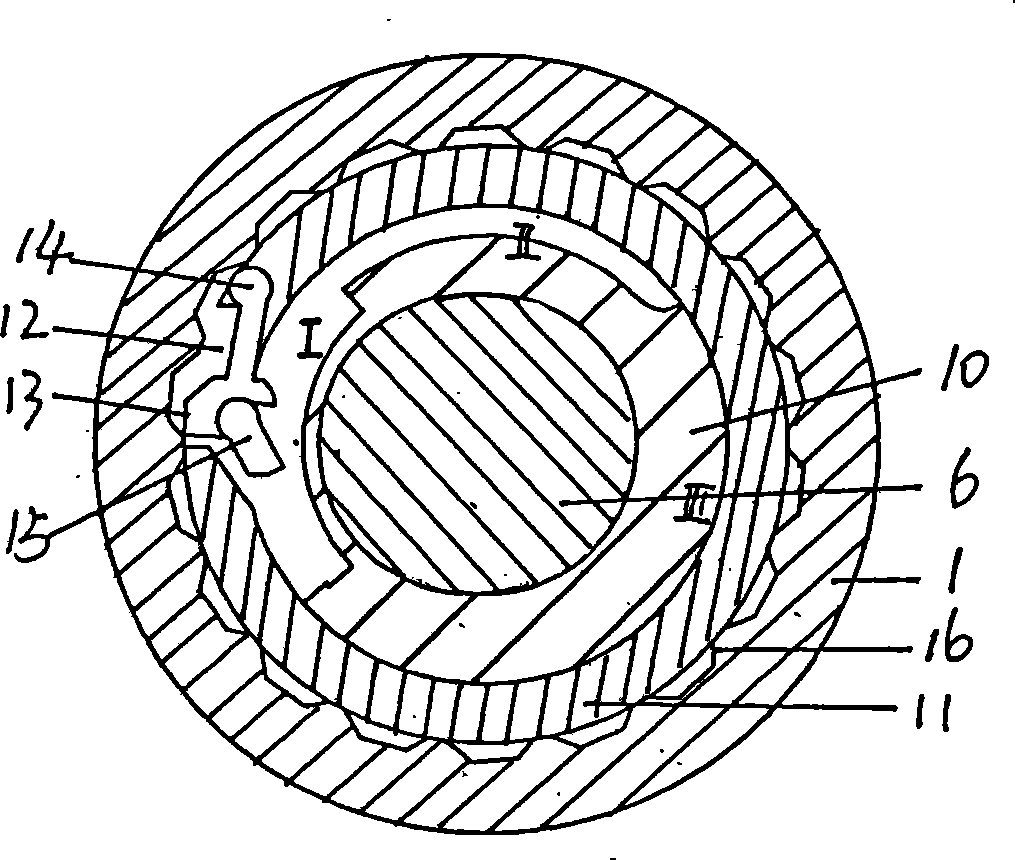

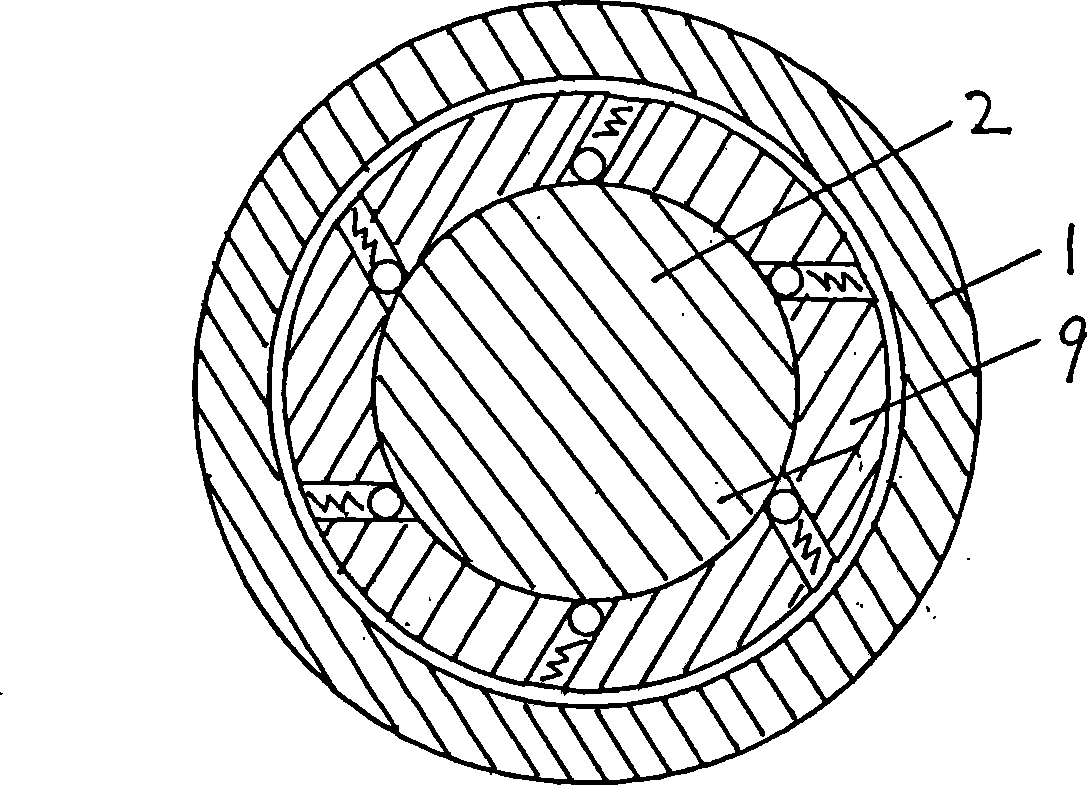

[0012] The mechanical continuously variable automatic transmission includes a housing 1, an output shaft 3 with a drive disc 2 fixed at the power input end, an input shaft 5 with a rotating disc 4 fixed at the power output end, and a drive disc 2 and an input shaft 5 placed on the output shaft 3 The intermediate shaft 6 between the rotating discs 4, the transmission disc 2 of the output shaft 3, the intermediate shaft 6, and the rotating disc 4 of the input shaft 5 are placed in the housing 1; on the outer circumference of the disc surface of the intermediate shaft 6 on the rotating disc 4 A ring-shaped fixed body 7 is provided, at least one ring-shaped torsion spring 8 is fixed between one end of the intermediate shaft 6 and the ring-shaped fixed body 7 on the rotating disk 4, and the other end is fixed with a unidirectional The output driving disc 9 of the overrunning clutch, the intermediate shaft 6 is also covered with a torque adjusting disc 10 placed between the output dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com