High-efficiency and energy-saving gas compression string stacked type temperature raising, refrigerating, dehumidifying and drying device

A technology of gas compression, refrigeration and dehumidification, which is applied in the directions of drying gas arrangement, drying solid materials, and heating to dry solid materials. Good effect of material processing and preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

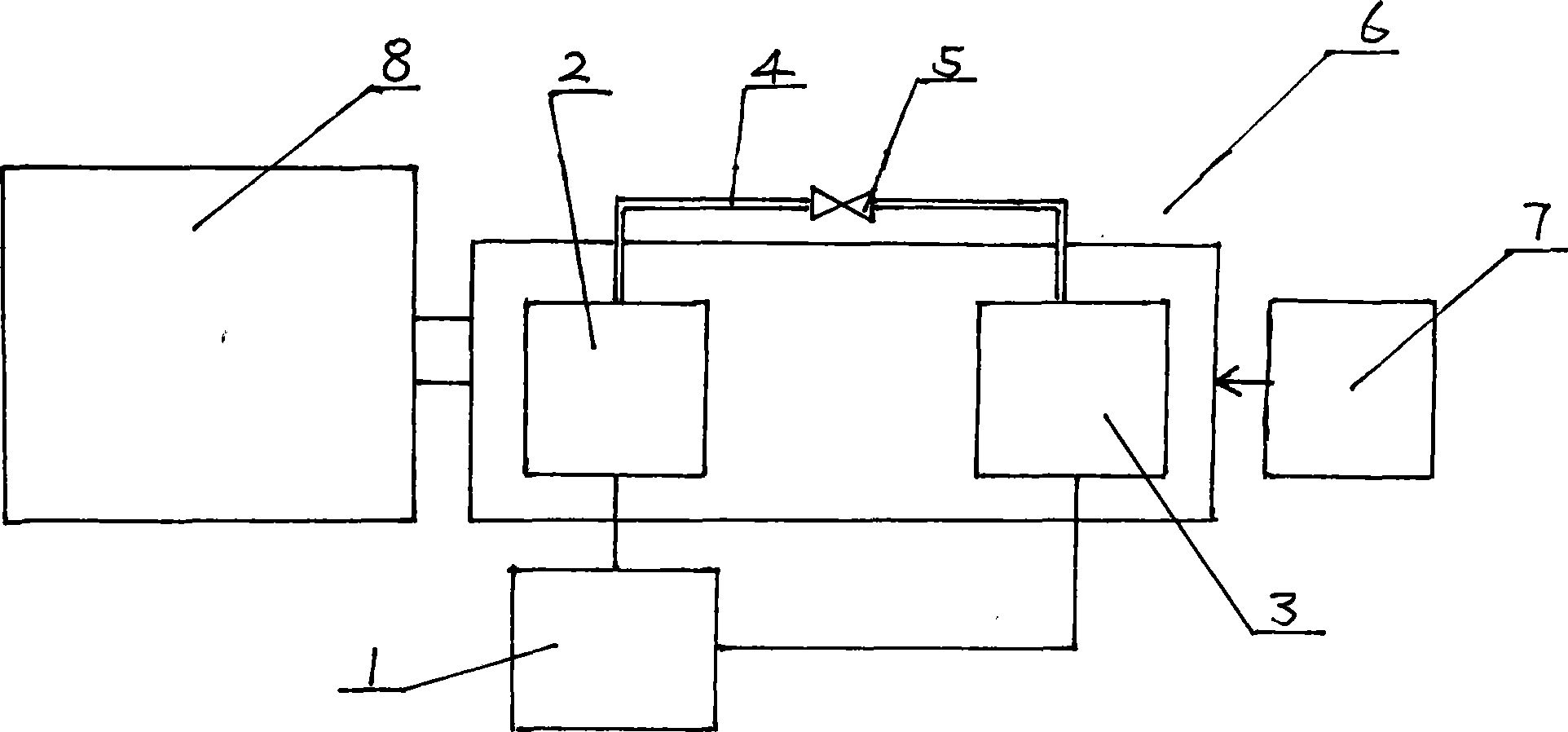

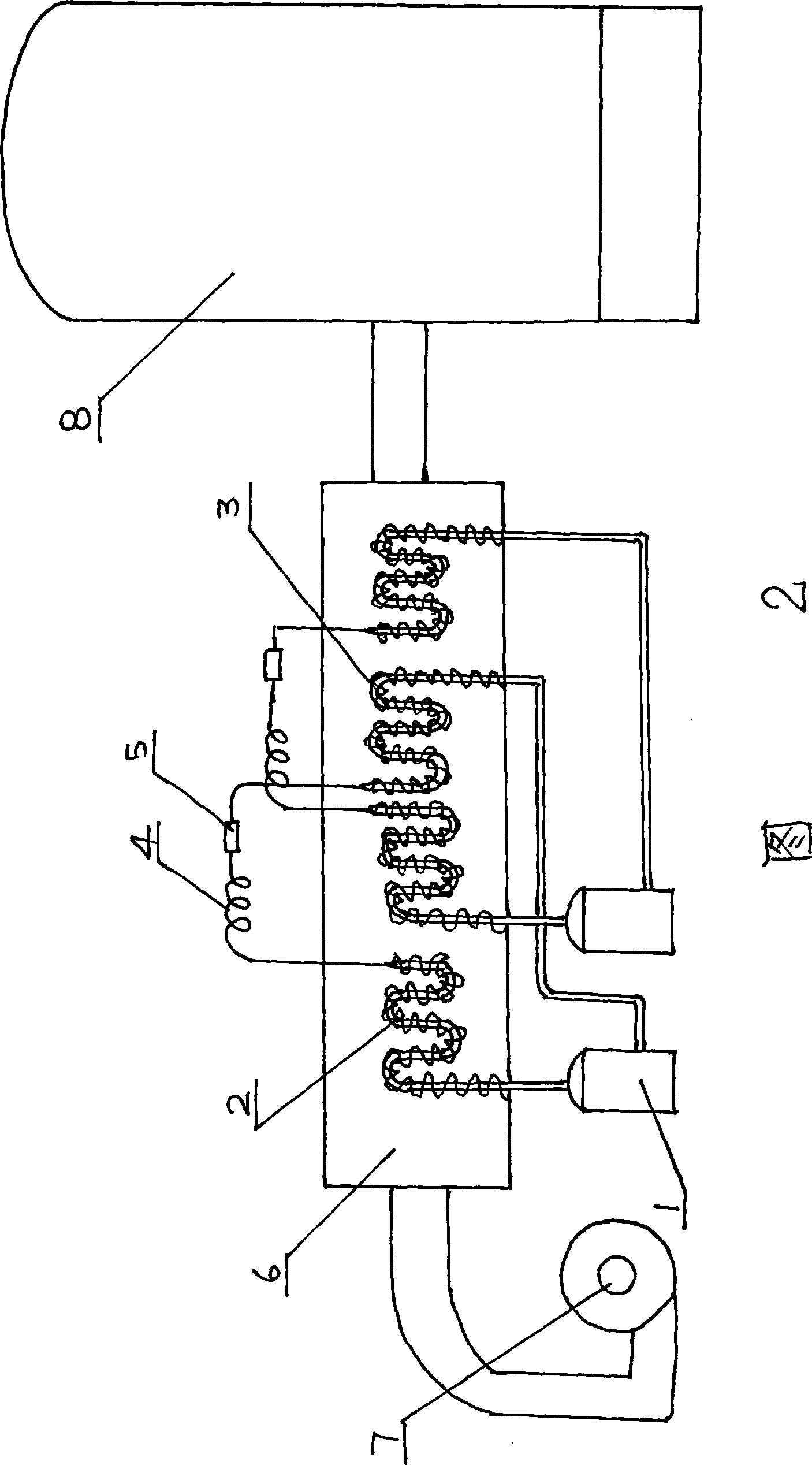

[0017] Embodiment 1: It consists of two gas compression and temperature raising refrigeration units cascaded. Each gas compression and temperature raising refrigeration unit consists of an air compressor 1, a high-pressure heater 2, a low-pressure refrigerator 3 and a thin tube 4 and a throttle valve 5; the outlet pipe of the air compressor 1 is connected to the high-pressure heater 2, the intake pipe is connected to the low-pressure refrigerator 3, and the thin tube 4 and the throttle valve are connected between the high-pressure heater 2 and the low-pressure refrigerator 3 5 connection; the high-pressure heater 2 and the low-pressure refrigerator 3 are installed in the middle of the air duct 6, and the air duct 6 is installed with an induced draft fan 7 at one end of the low-pressure refrigerator 3, and the induced draft fan 7 is connected with the material concentration and drying vertical carrier equipment 8 connect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com