Apparatus and method for measuring welding tube corrosion under stress condition

A stress state, welded pipe technology, used in measuring devices, weather resistance/light resistance/corrosion resistance, material electrochemical variables, etc., can solve the problems of non-corrosive surface sealing, complex working electrode shape, etc., to reduce the impact and prevent overflow. and draining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below, the device and method for measuring welded pipe corrosion under stress state of the present invention will be further described in detail with reference to the accompanying drawings.

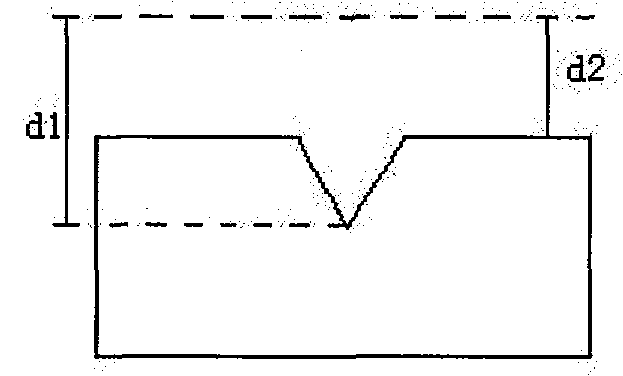

[0039] figure 1 In , the groove corrosion tendency is expressed by the groove corrosion sensitivity coefficient α. Soak the sample containing ERW (Electric Resistance Welding) seam in 3.5% NaCl aqueous solution, and then perform electrochemical accelerated corrosion on it, and then test the uniform corrosion depth d2 and groove corrosion depth d1 of the sample, and use groove corrosion The coefficient α represents the result of the experiment, where α=d1 / d2.

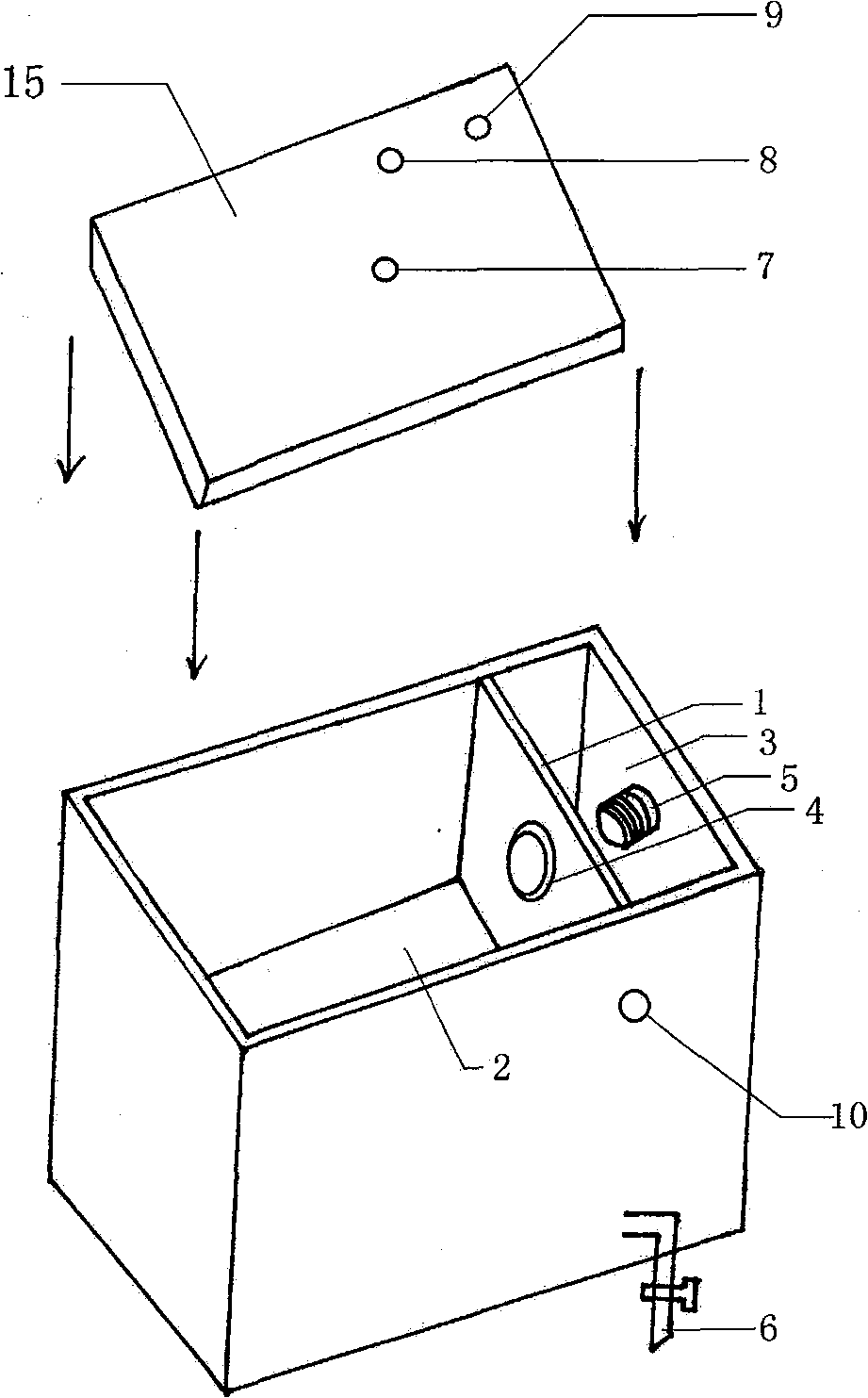

[0040] figure 2 Among them, the electrolytic cell assembly is made of transparent plexiglass plates, preferably rectangular.

[0041] A separator 1 is arranged in the middle of the electrolytic cell assembly, which divides the electrolytic cell assembly into two parts, an electrolytic cell 2 and an electrode installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com