Flexible loading system for stope mine pressing three-dimensional physical simulation test stand

A flexible loading system and a technology for simulating test benches, which are used in measuring devices, instruments, scientific instruments, etc., can solve problems such as the inability to objectively simulate the actual situation of rock formations, and achieve the effect of overcoming negative effects and improving test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

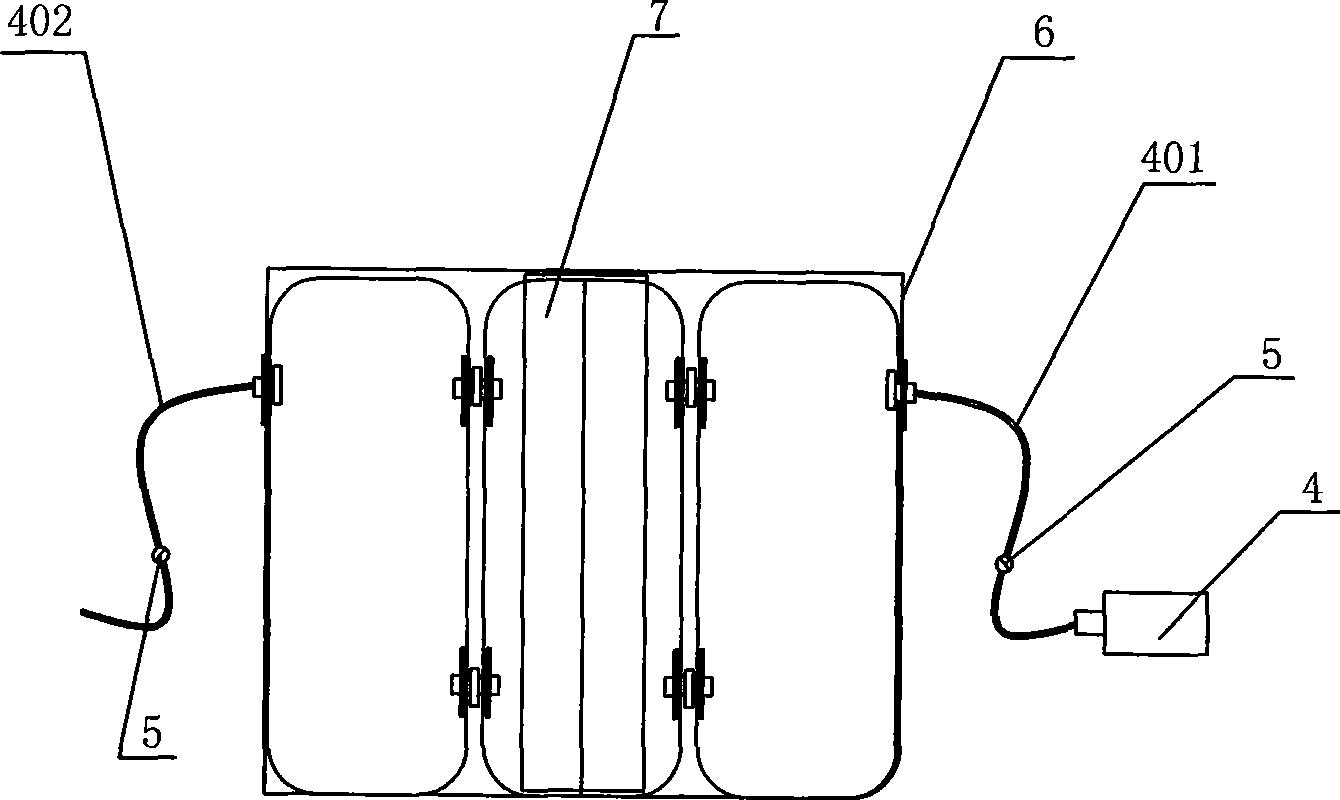

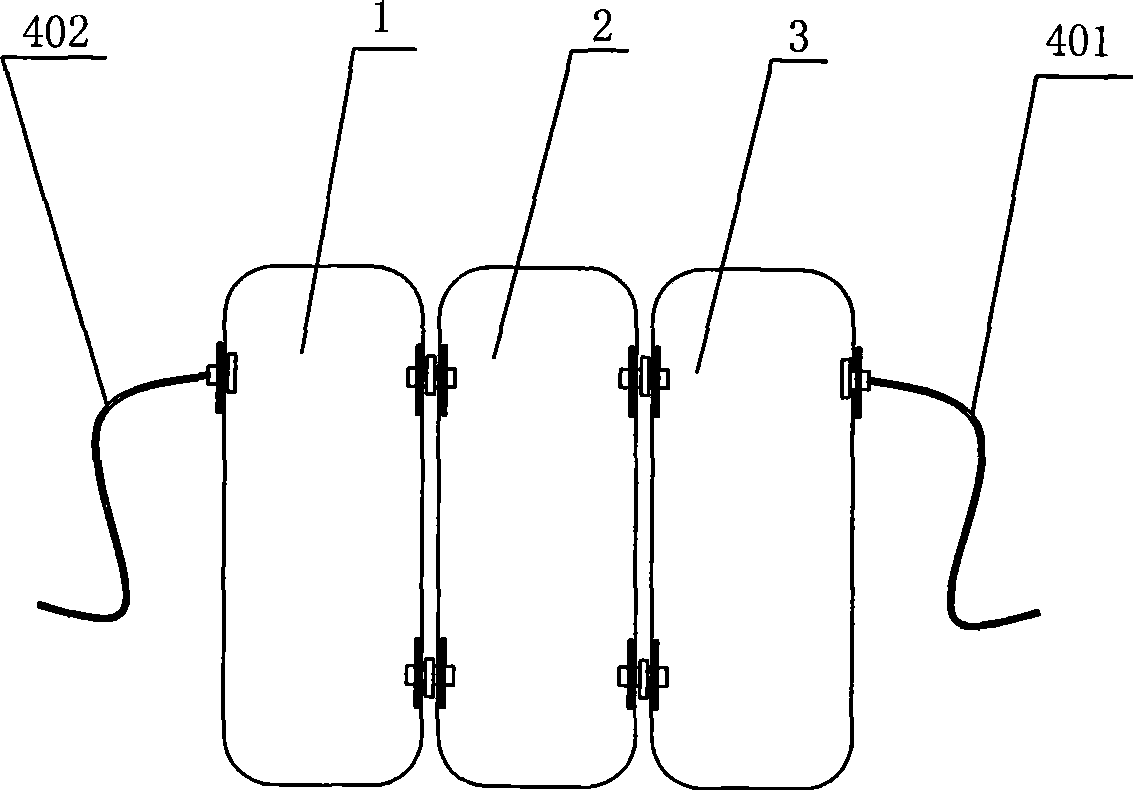

[0015] combine figure 1 and figure 2 , a flexible loading system for a three-dimensional physical simulation test bench of mine pressure in a stope, including a pressure providing device and a model; a liquid-filled bladder is arranged between the pressure providing device and the model, and the pressure provided by the pressure providing device passes through the liquid-filled bladder Acts on the model surface. Emphatically explain below the innovation part in the present invention creation:

[0016] There are multiple liquid-filled skin bags, three in an example, that is, liquid-filled skin bags 1, 2, and 3. The liquid-filled skin bags 1, 2, and 3 are arranged in sequence, and all the liquid-filled skin bags are connected in sequence. The liquid-filled bladder is configured with a liquid supply system 4, and the liquid supply system 4 is provided with a liquid supply pipeline 401 and a liquid return pipeline 402, and a flow meter 5 is arranged on the liquid supply pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com