Method for enhancing rigidity of bayonet of stainless steel vernier caliper

A technology of vernier caliper card and vernier caliper, which is applied in the field of vernier caliper, can solve the problems of easy cracks, inability to obtain stable hardness, and little effect, and achieve the effect of improving the hardness of the bayonet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings.

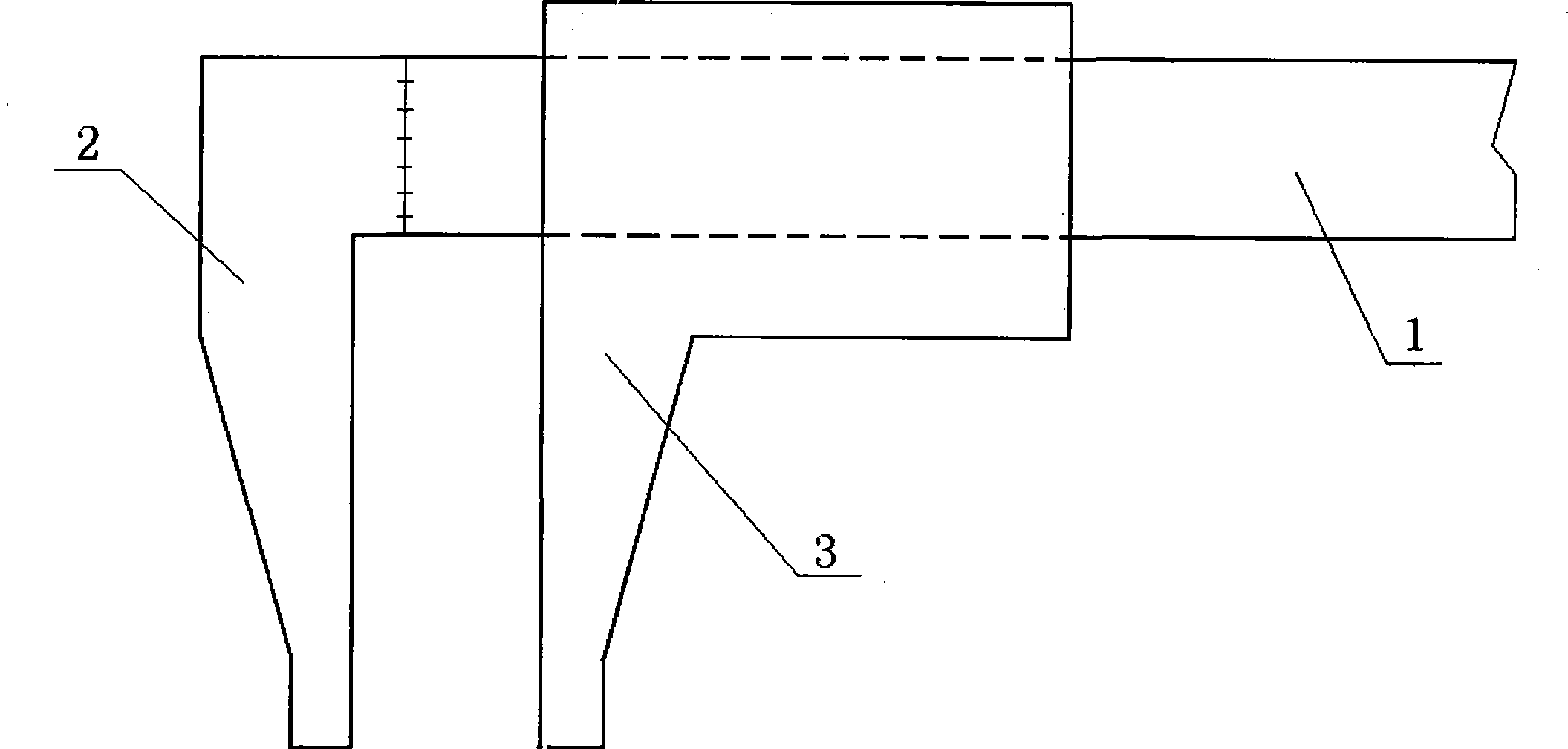

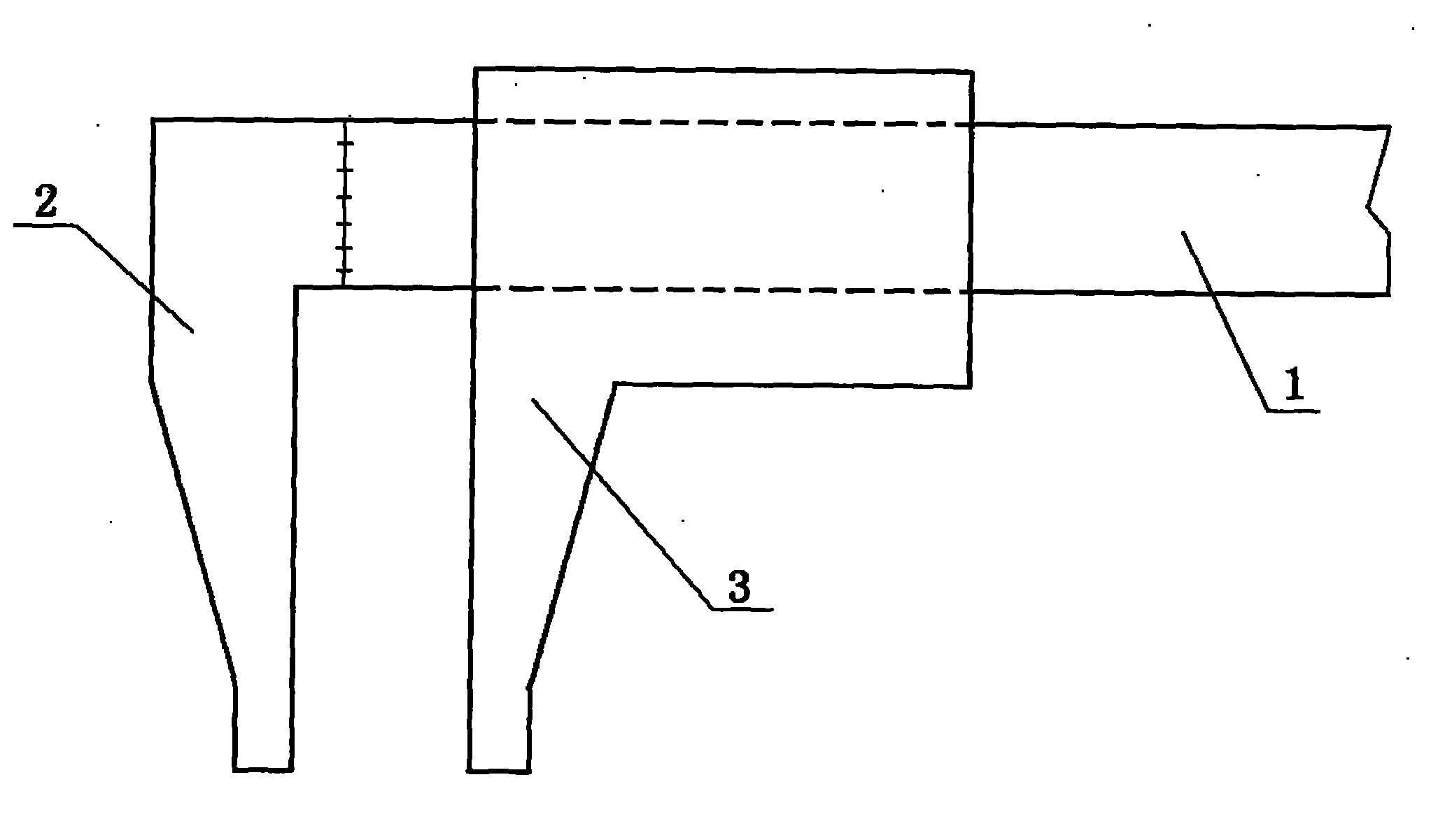

[0010] figure 1 It is a structural schematic view of the vernier caliper of the present invention. The present invention aims at the deficiencies of the existing vernier caliper, and at the same time combines the transformation experience, works hard on the material selection of the vernier caliper, and selects a 6Cr16 material with high carbon content and high Cr content, which is subjected to high-frequency quenching It can stably make the hardness reach 58HRC. However, due to the high price of this material, considering the economy of the finished product, the main ruler body is divided into two parts: the ruler body 1 and the ruler head 2. The ruler body 1 is made of 4Cr13 material with slightly lower hardness and cheaper price. The head 2 is made of 6Cr16 material with high hardness, the ruler body 1 and the ruler head 2 are fixedly connected together by butt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com