Tacheometry apparatus for microminiature turbojet

A turbojet and rotational speed measurement technology, applied in the field of signal measurement, can solve the problems of short effective sensing distance of sensors, easy to be affected by body vibration, poor temperature stability, etc., and achieve the effects of wide rotational speed measurement range, light weight and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

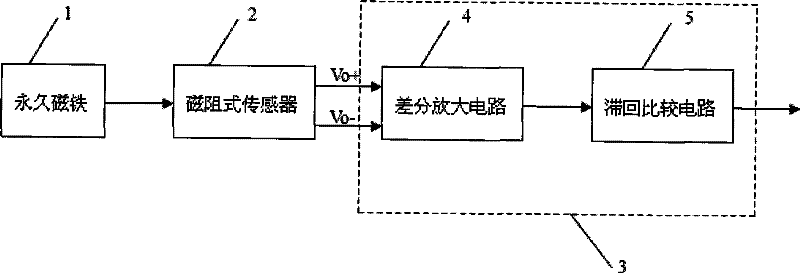

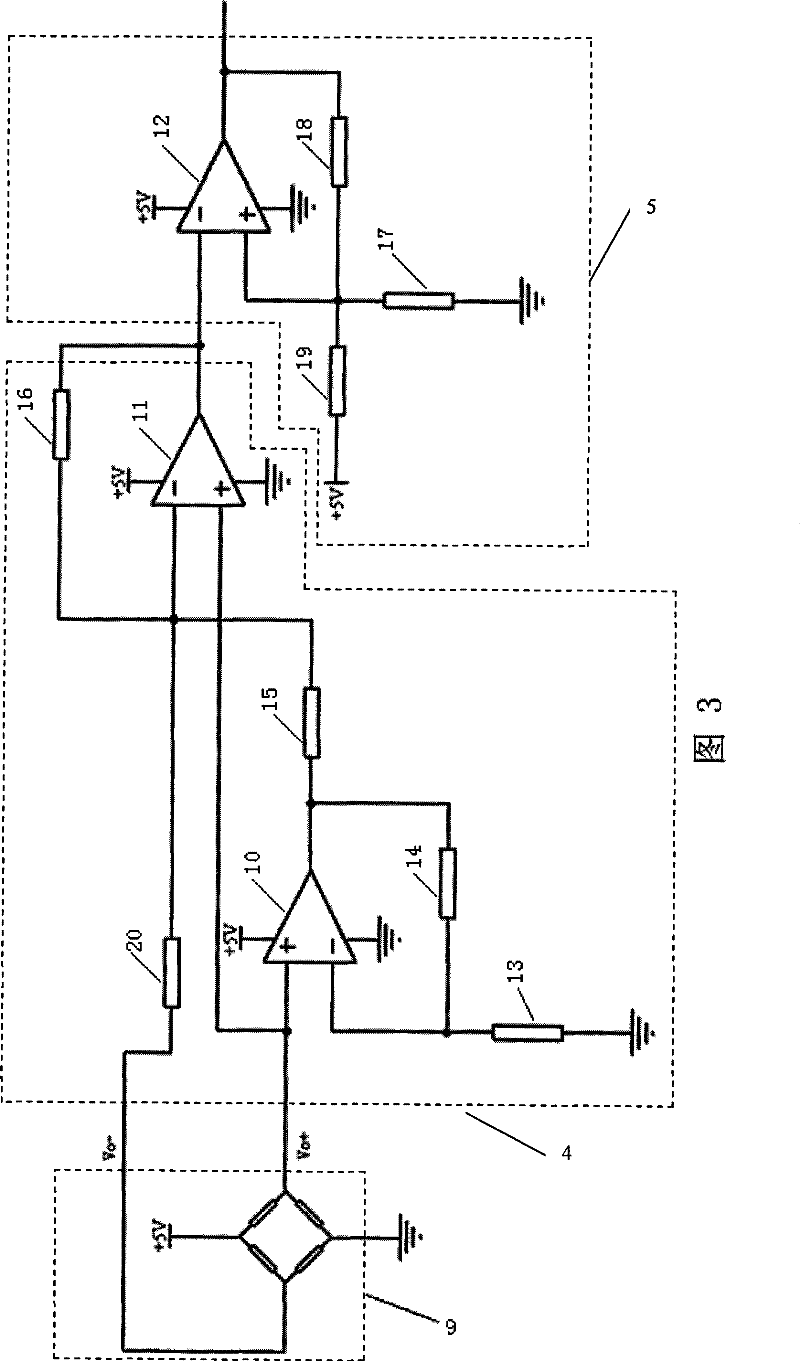

[0028] Such as figure 1 Shown is a block diagram of the overall structure of the present invention. The main part of the rotational speed measuring device of the present invention is composed of a permanent magnet 1, a magnetoresistive sensor 2 and a rotational speed signal processing circuit 3. The rotational speed signal processing circuit 3 is composed of a differential amplifier circuit 4 and a hysteresis comparator circuit 5.

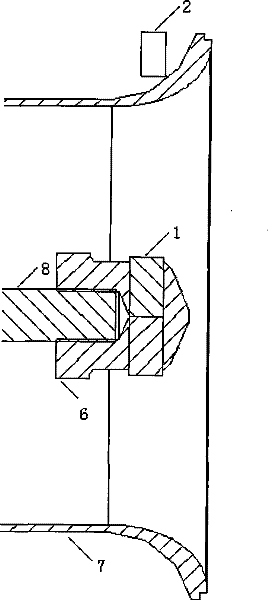

[0029] The magnetoresistive sensor 2 installed on the engine has a Wheatstone bridge composed of resistors made of ferromagnetic alloy. After power on, there is current flow in the magnetoresistive sensor bridge 9 inside the magnetoresistive sensor 2 However, as the engine rotor rotates, the permanent magnet 1 on it generates an alternating magnetic field perpendicular to the direction of the current in the magnetoresistive s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com