Internal information testing method of secondary battery and apparatus

A technology of secondary batteries and internal information, applied in secondary batteries, battery circuit devices, measuring devices, etc., can solve problems such as battery disintegration, battery can no longer be used, and application scope limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

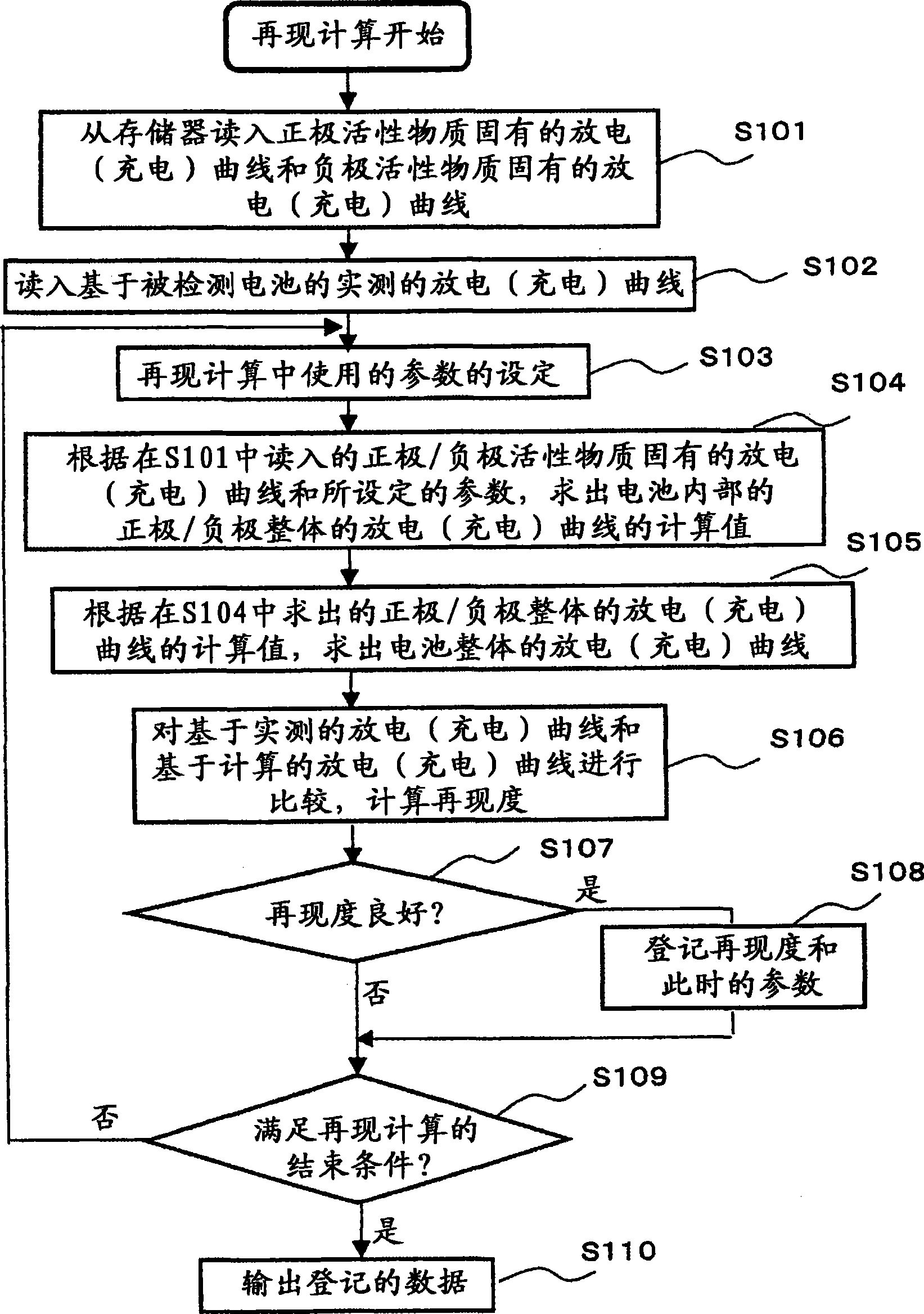

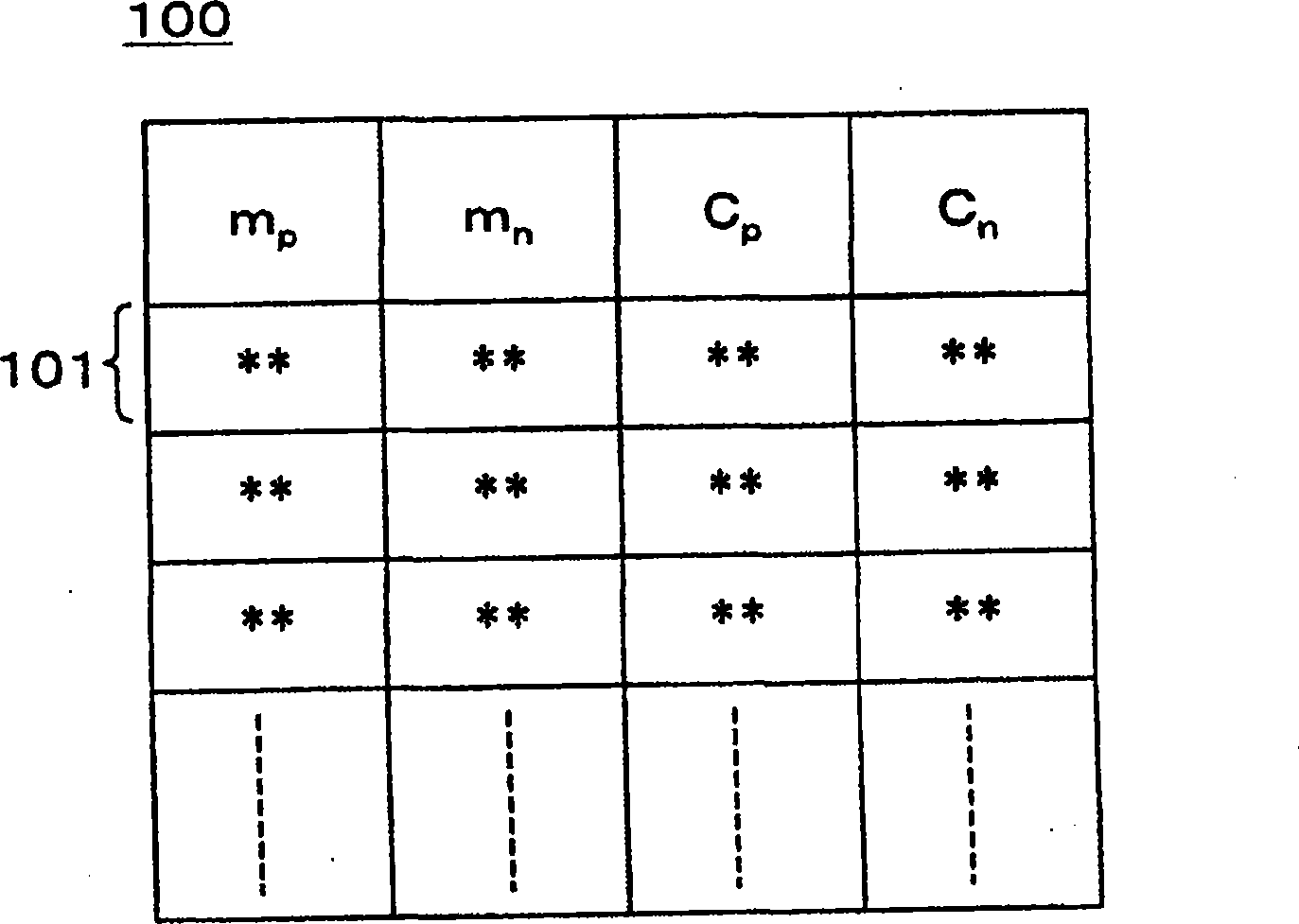

[0076] For example, when becoming (1) positive effective active material mass m p Less than 70% of the initial value, (2) The amount of effective active material in the negative electrode m n 70% or less of the initial value, (3) From the position index (C n -C p ) is any one of 20% or less of the discharge capacity at the time of measurement, the calculation device 10 outputs a signal suggesting replacement of the detected battery via the output device 13 . In addition, the threshold used for determination can be set for each system according to the material of the active material constituting the battery, the ratio of the active material of the positive electrode and the negative electrode at the time of battery design, required performance, and the like.

[0077] (Operation example 2)

[0078] When the potential of the positive electrode or the negative electrode is outside the specified range in the battery utilization range specified by the upper limit voltage and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com