Method and system for semi-chemical pulping

A technology of semi-chemical pulp and cooking vessel, which is applied in the field of semi-chemical pulp and system, and can solve the problems of uneconomical operation and side effects of pulp yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

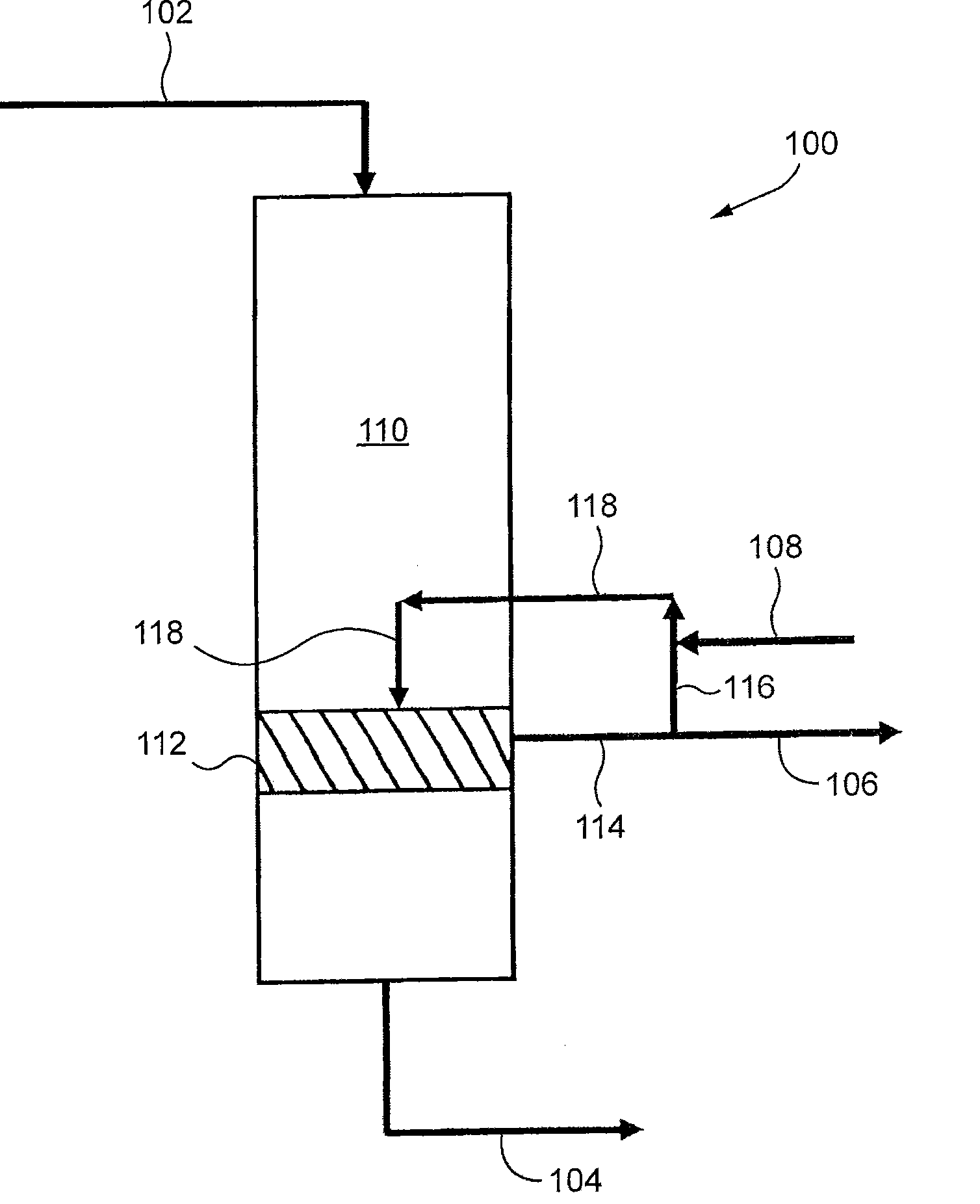

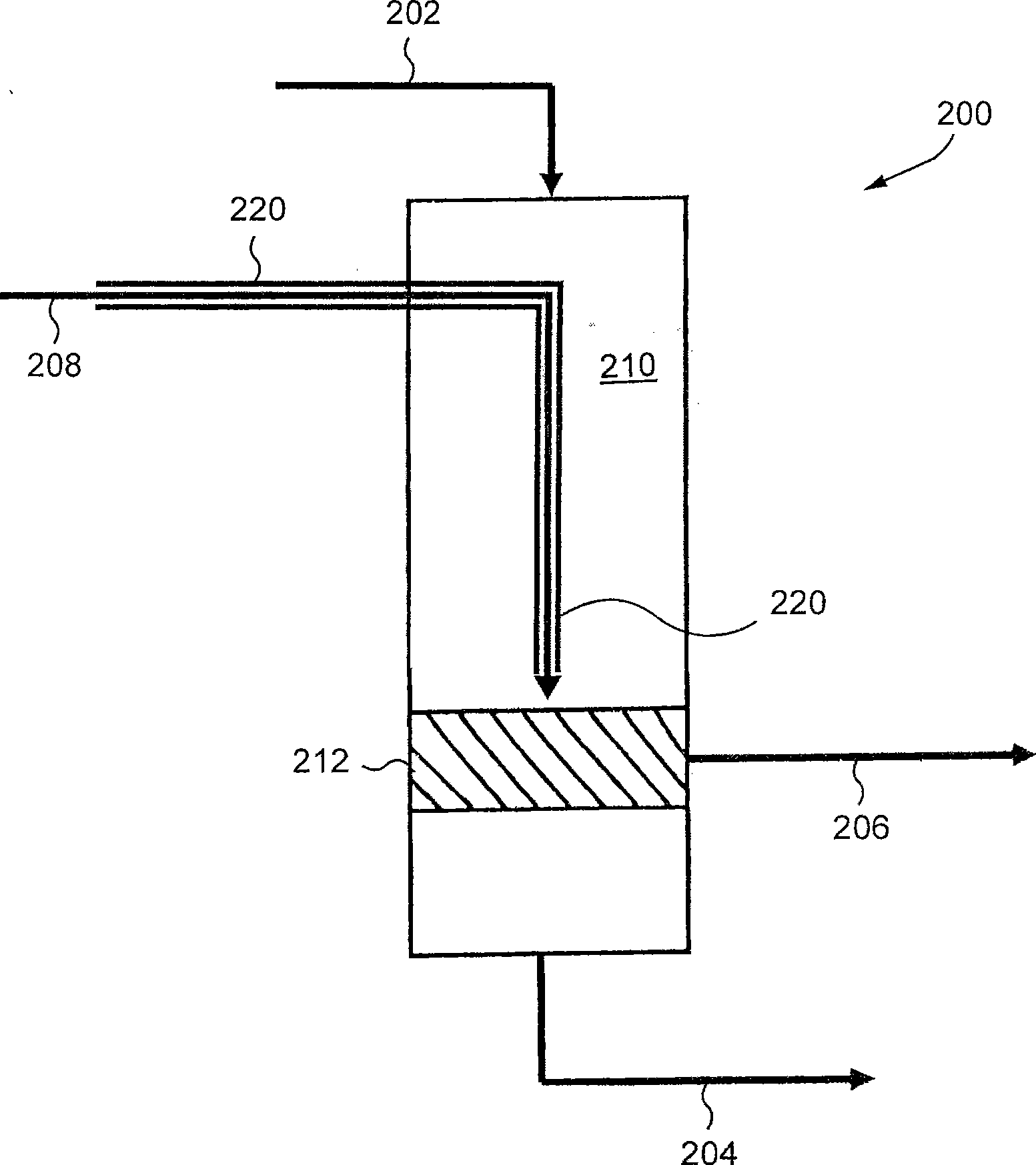

[0014] In one aspect, certain embodiments of the invention generally involve increasing the pH at the end of cooking. This keeps the extraction sieve clean for a longer period of time. The pH can be raised by adding white liquor or NaOH (or any other base) at the end of the cook through the loop and / or base pipe.

[0015] The pH of the cooking liquor (eg lignin-containing black liquor) at the end of cooking should be 10 or higher, preferably between 10-13, most preferably between 10-12.

[0016] According to some embodiments of the invention, the pH at or near the extraction screen may be increased compared to the pH of the liquid above the extraction screen. This in turn increases the solubility of lignin at or near the extraction screen.

[0017] In certain embodiments, the pH level of the liquid at or near the extraction screen in the vessel undergoing semi-chemical slurrying is increased. In certain embodiments, this increases the solubility of the lignin and also reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com