Lens

A lens and non-optical part technology, applied in the optical field, can solve problems affecting the image quality of the lens module, extrusion deformation of the lens assembly into the lens barrel, discarding of the lens module, etc., to improve assembly yield and not easy to squeeze Deformation, the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

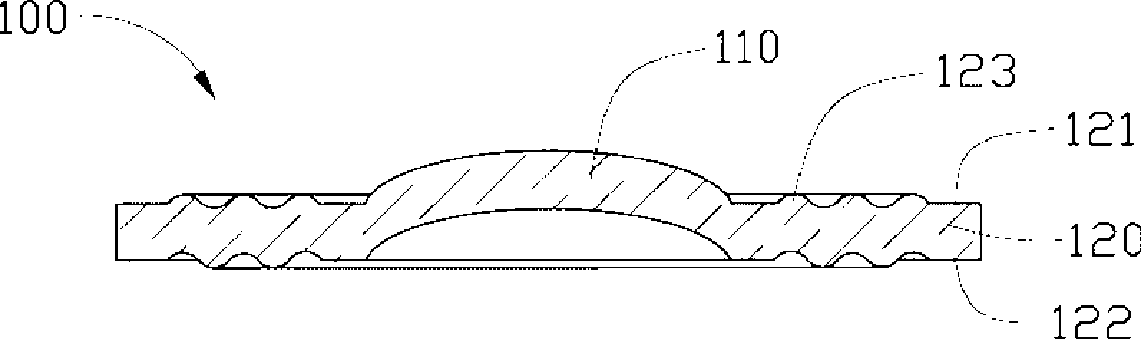

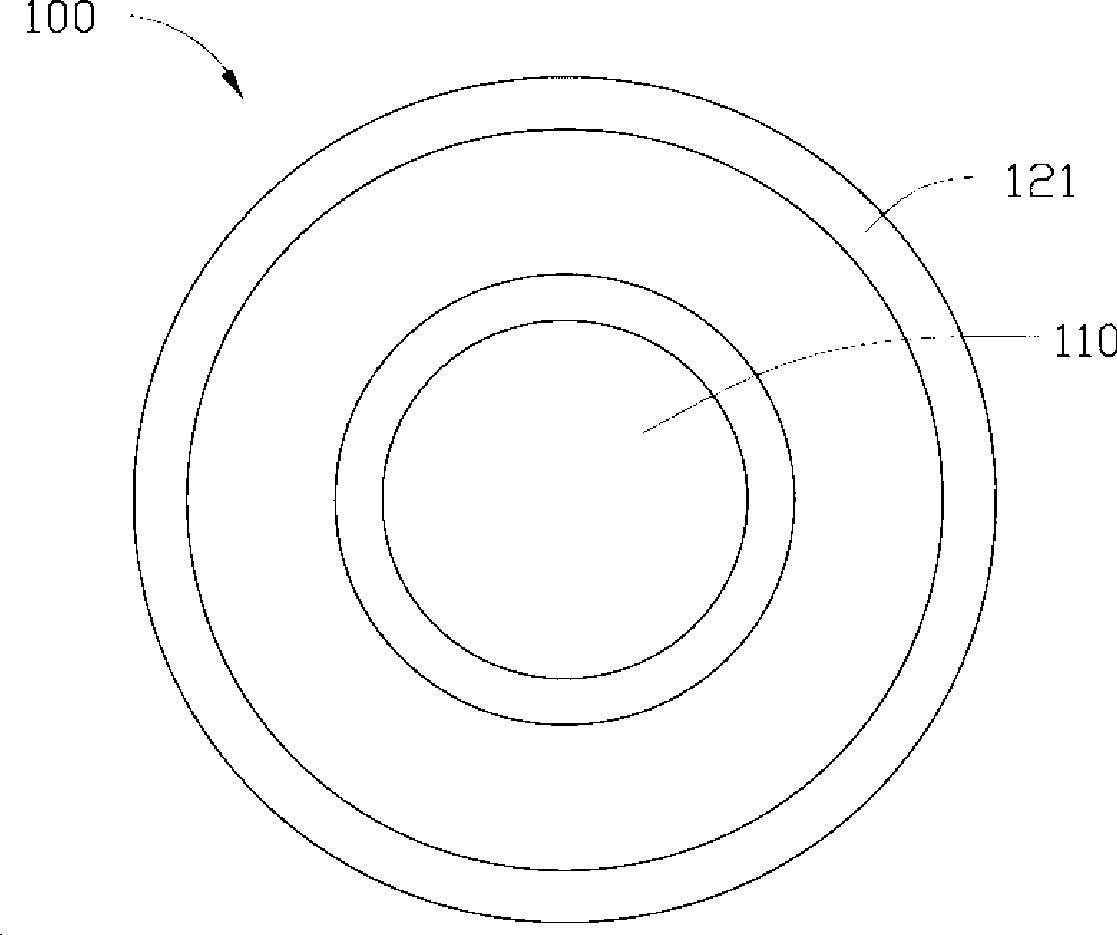

[0017] see figure 1 and figure 2 The lens 100 provided by the embodiment of the present invention includes an optical part 110 located at the center of the lens and a non-optical part 120 located at the periphery of the center of the lens. The optical part 110 can achieve a predetermined optical effect during the imaging process. The non-optical part 120 does not participate in the imaging process, but is mainly used to realize the installation and fixation of the lens in the lens barrel.

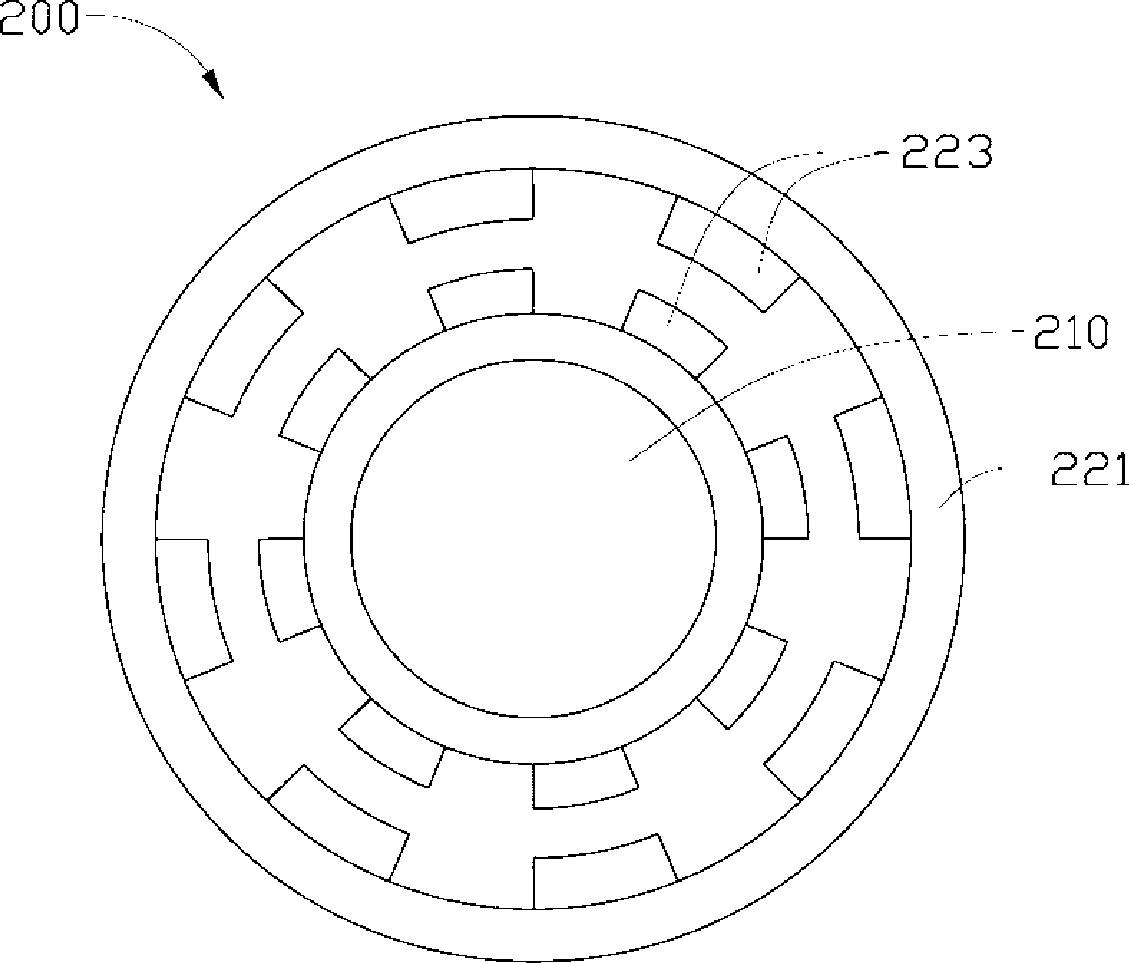

[0018] The non-optical part 120 has two opposite surfaces 121 and 122, and there are a plurality of protrusions 123 on the two opposite surfaces 121 and 122 of the non-optical part 120, and the plurality of protrusions 123 are arranged along the lens. The optical part 110 extends in the circumferential direction of at least one concentric circle at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com