Timepiece

A clock and watch mirror technology, applied in the field of fixed structure, can solve the problems of clock and watch enlargement and weight increase, the casing exceeds the thickness and diameter, and the casing produces redundant parts, etc., so as to improve the interest, reduce the size and improve the durability shocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Hereinafter, one embodiment of the present invention will be described with reference to FIGS. 1 to 8.

[0053] [1. Overall structure]

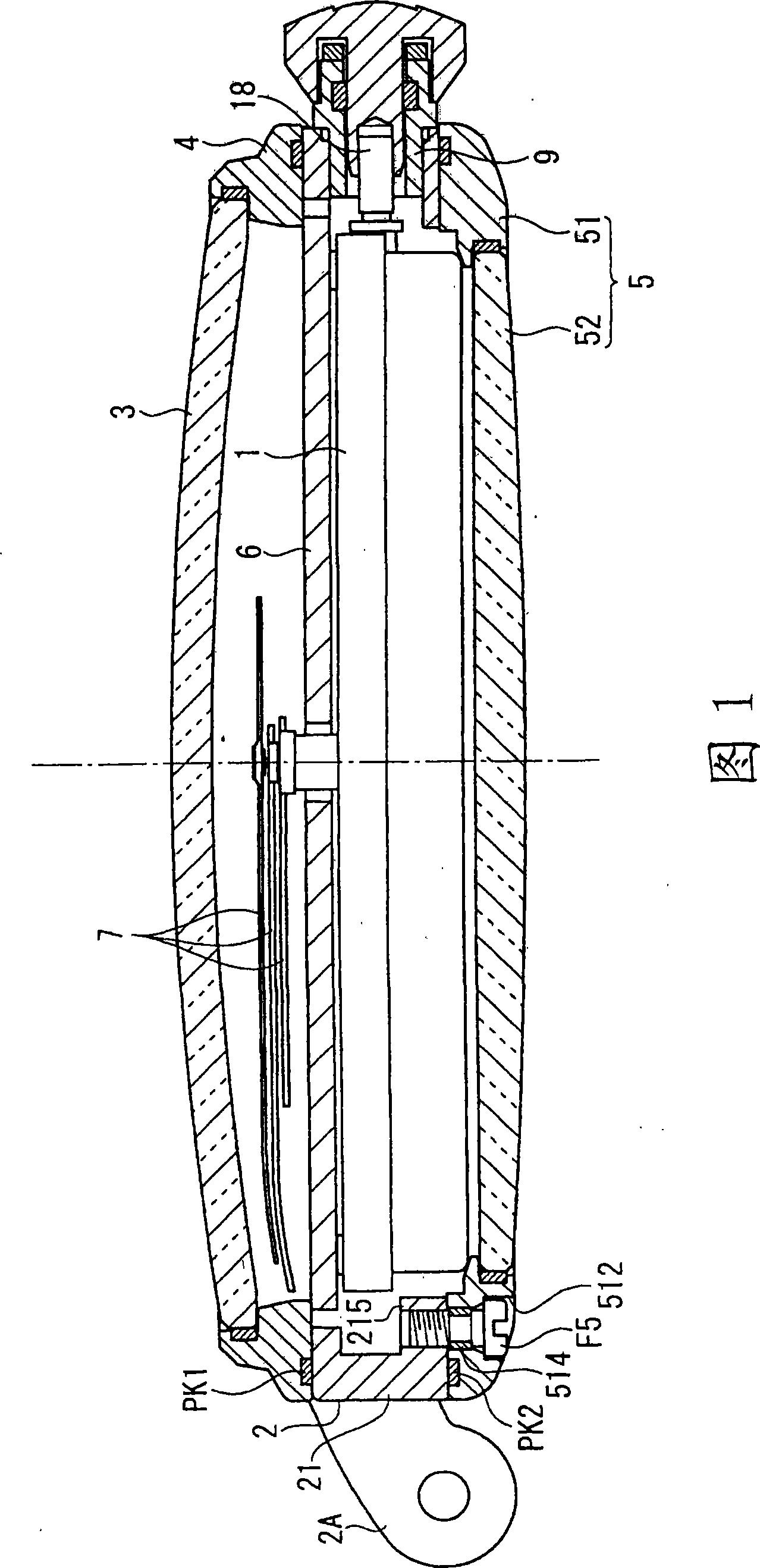

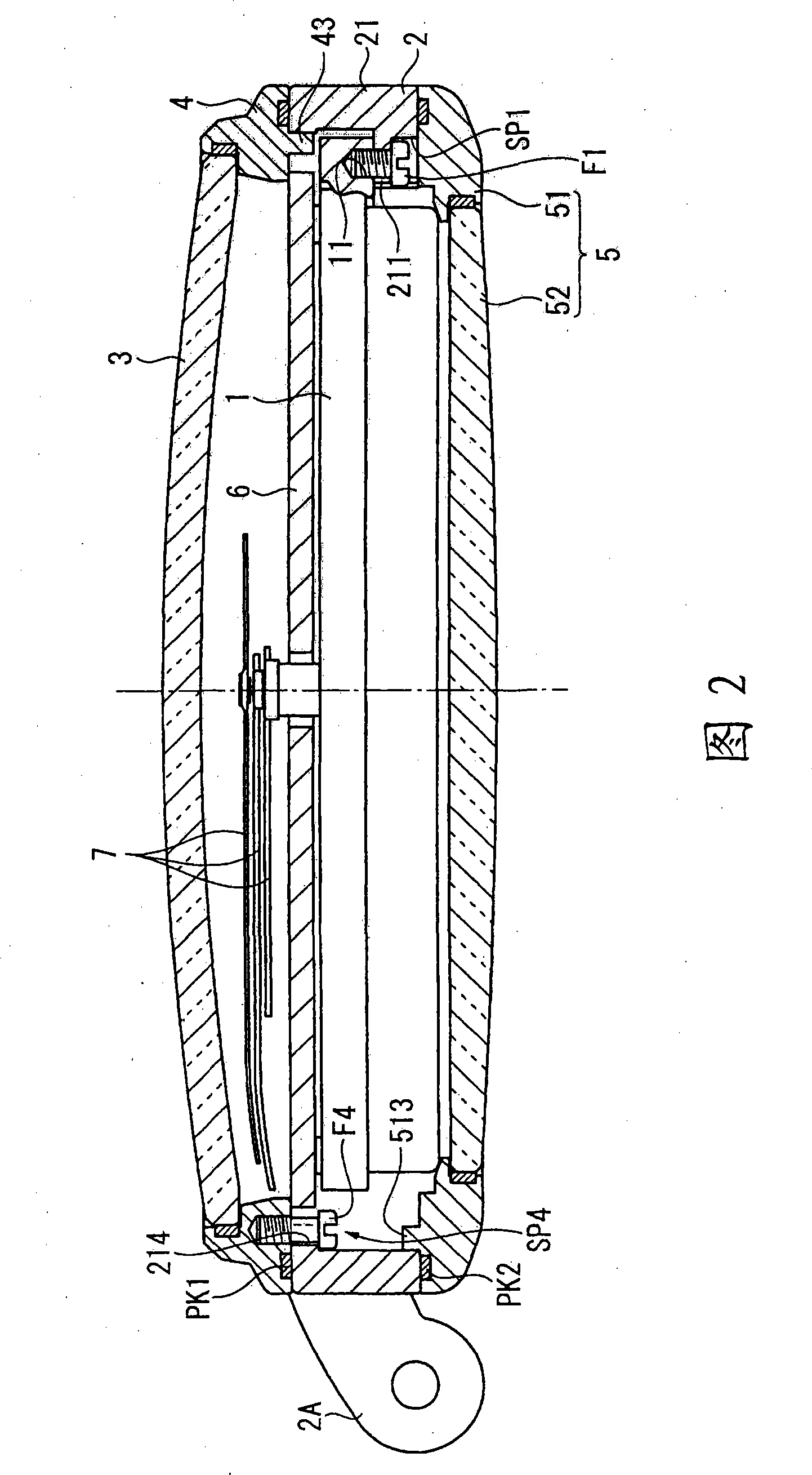

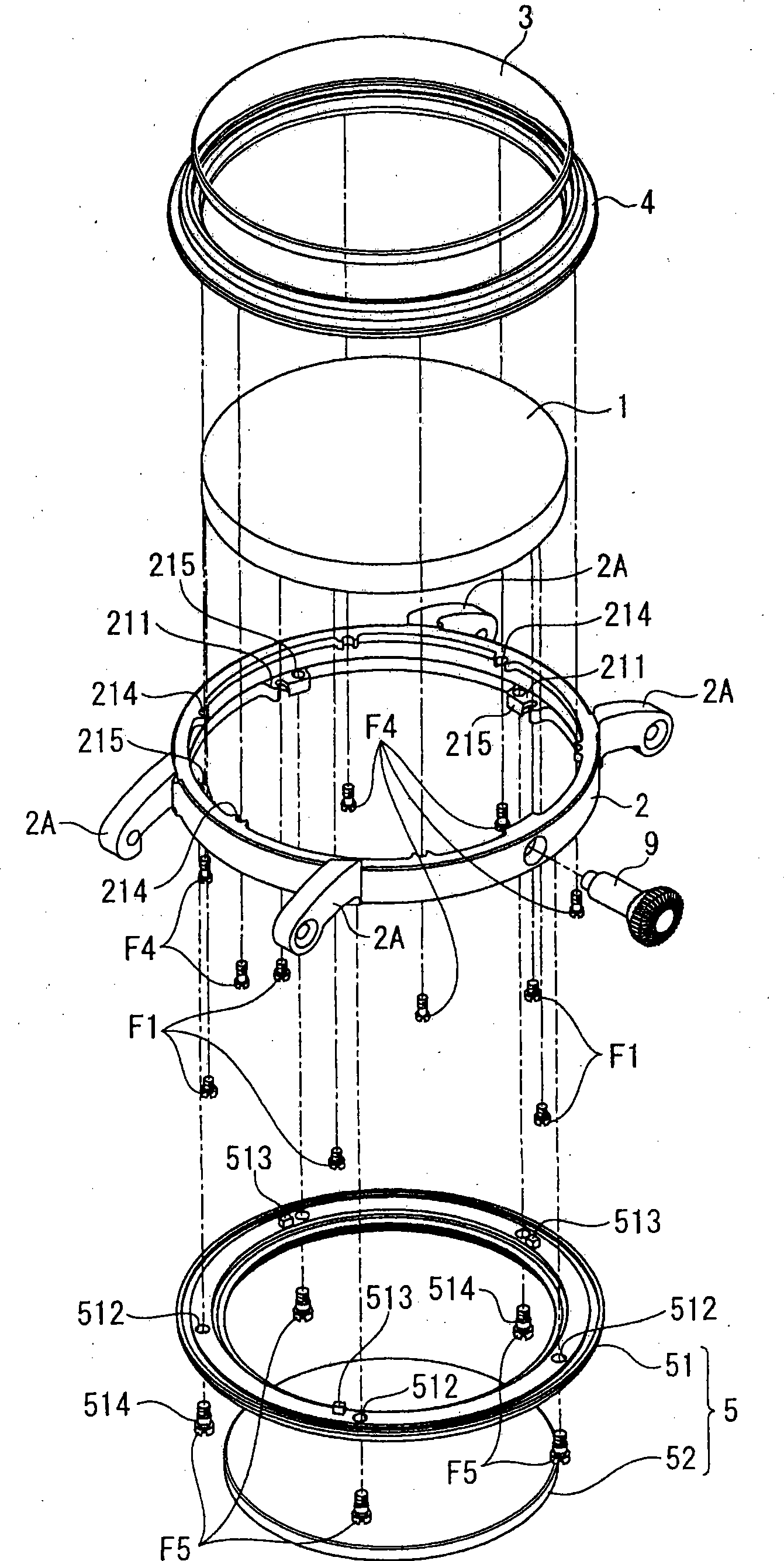

[0054] 1 and 2 are longitudinal cross-sectional views of the timepiece of this embodiment, image 3 It is an exploded perspective view of the timepiece of this embodiment. In addition, the left side of the vertical line in FIG. 1 shows a cross section in the 12 o'clock direction, and the right side shows a cross section in the 3 o'clock direction.

[0055] The timepiece of this embodiment includes: a timepiece body (movement) 1 having a drive source such as a clockwork (not shown), a drive train, a speed regulating mechanism, a stepping motor, etc.; and a substantially cylindrical housing 2 that houses it Watch body 1; watch glass 3; ring-shaped glass outer ring 4, which holds the peripheral edge of the watch glass 3; and a back cover 5, which is arranged on the opposite side of the case 2 on which the watch glass 3 is provided side. The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com