Ablation-proof electric power plug with power line rotatable

A power plug, anti-ablation technology, used in flexible/rotatable wire connectors, circuits, electrical components, etc., can solve problems such as damage to the bent part of the plug, easy damage to electrical equipment, inconvenience, etc. Simple and convenient, the connection is not easy to damage the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

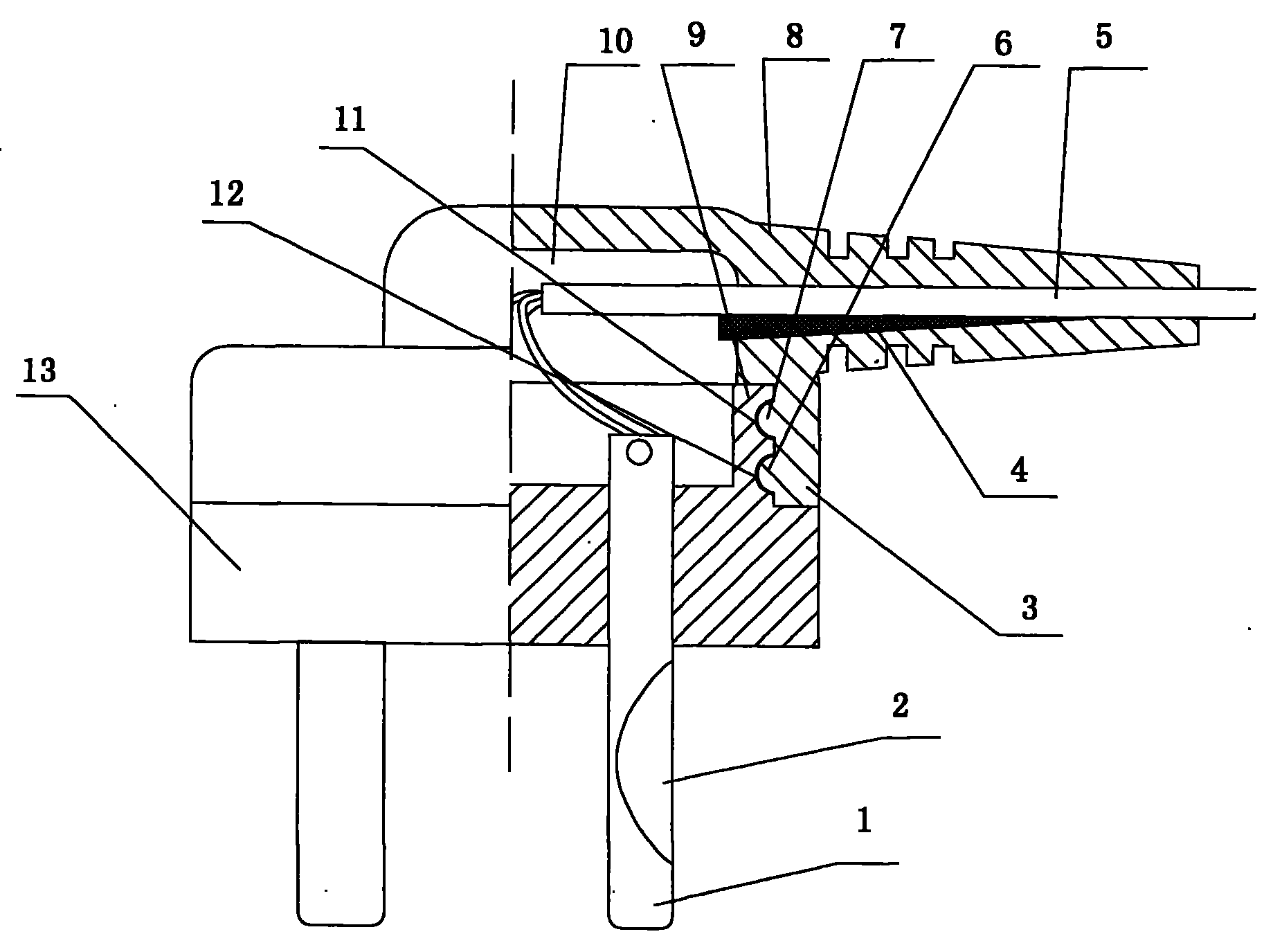

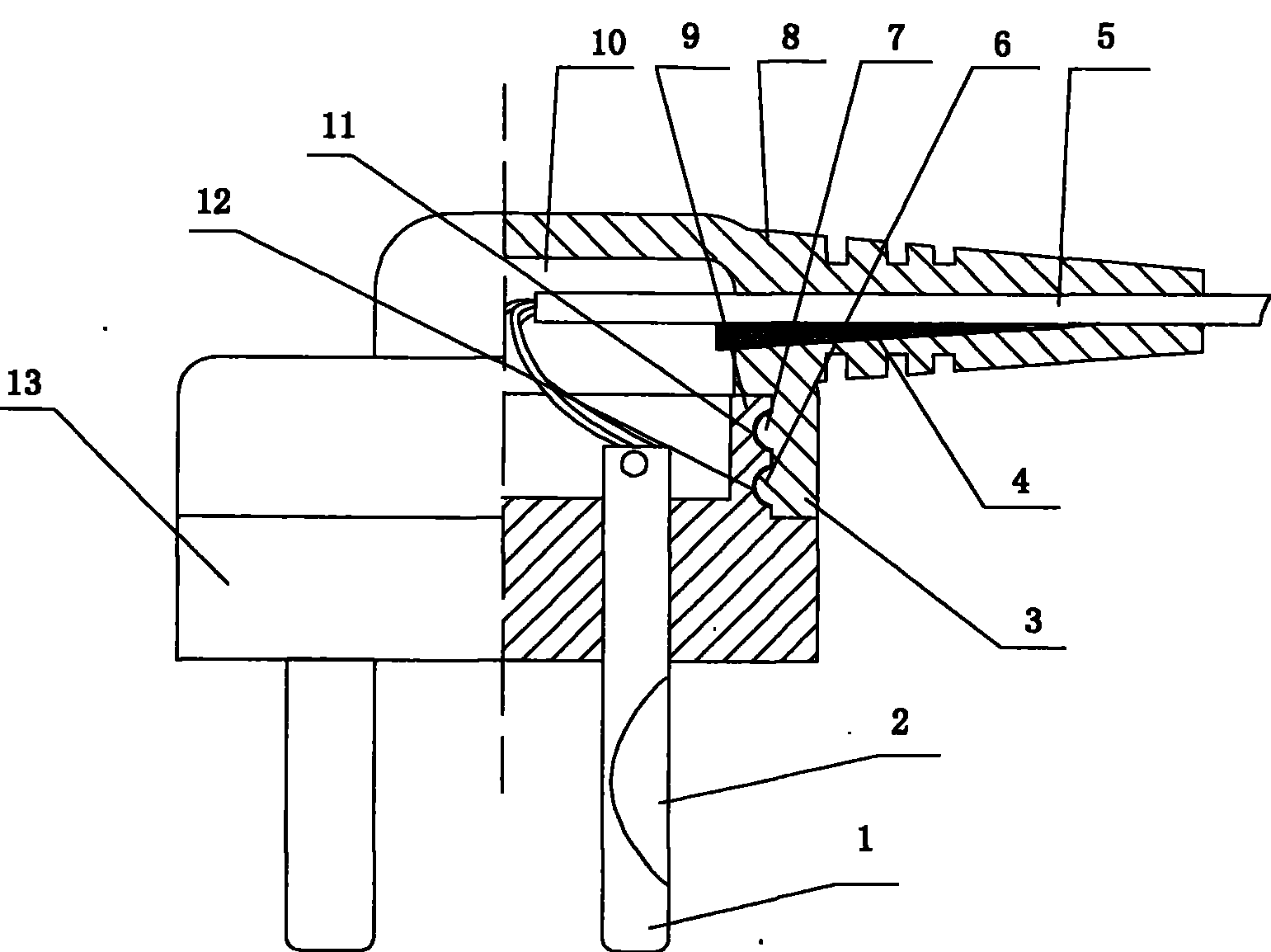

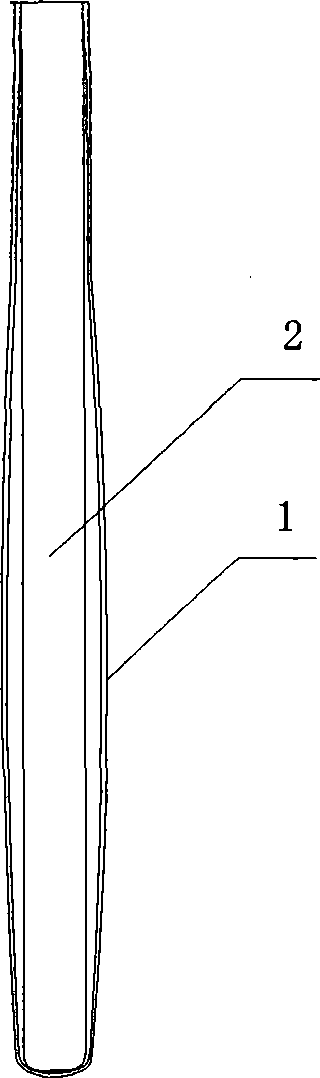

[0023] Embodiment: The processing and production of the anti-ablation power plug of the present invention is very simple. Both the upper cover and the base of the plug are made by injection molding technology, and the use is also very simple. Penetrate through the tapered hole, connect with the electrode by bolts or welding, then fix the power cord in the tapered hole with plastic or wooden wedges, and finally make the rotating upper cover and the plug base snap together through the bite structure. During installation, the outer sheath of the power cord preferably extends to the middle of the cavity between the rotating loam cake and the base to facilitate the twisting of the electric wires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com