Novel atomizing pump electrified aluminum-shell sealing assembly machine

A technology of anodized aluminum and spray pumps, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of fast wear of guide keys, high assembly scrap rate, and low production efficiency, so as to improve assembly accuracy and increase guiding Position, the effect of reducing defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

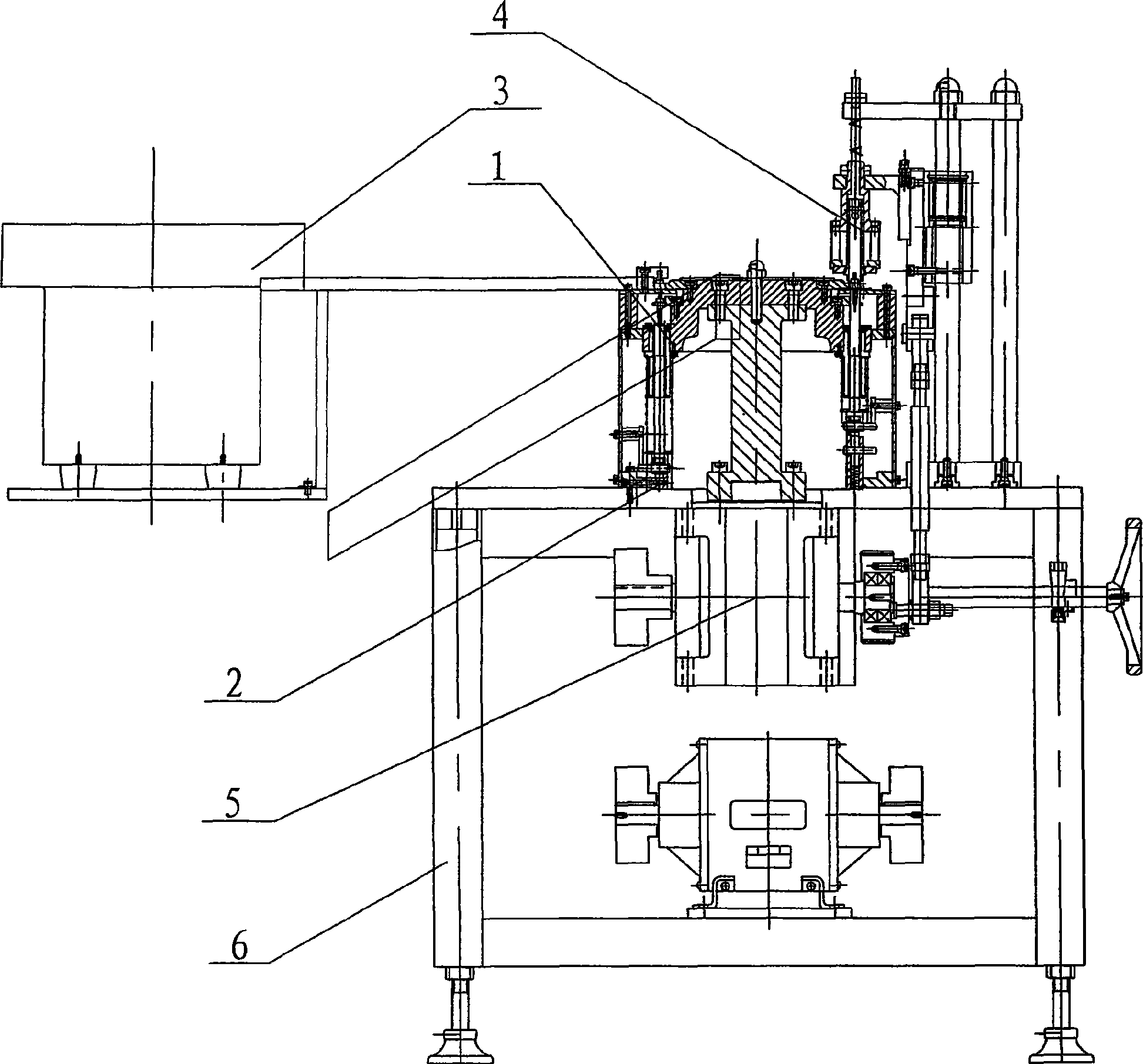

[0031] See figure 1 , The new spray pump electrochemical aluminum shell gripping assembly machine involved in the present invention is mainly composed of a base 6, a turntable mechanism 1, a convex rail lifting mechanism 2, a vibrating plate feeding mechanism 3, a gripping mechanism 4, and a divider mechanism 5.

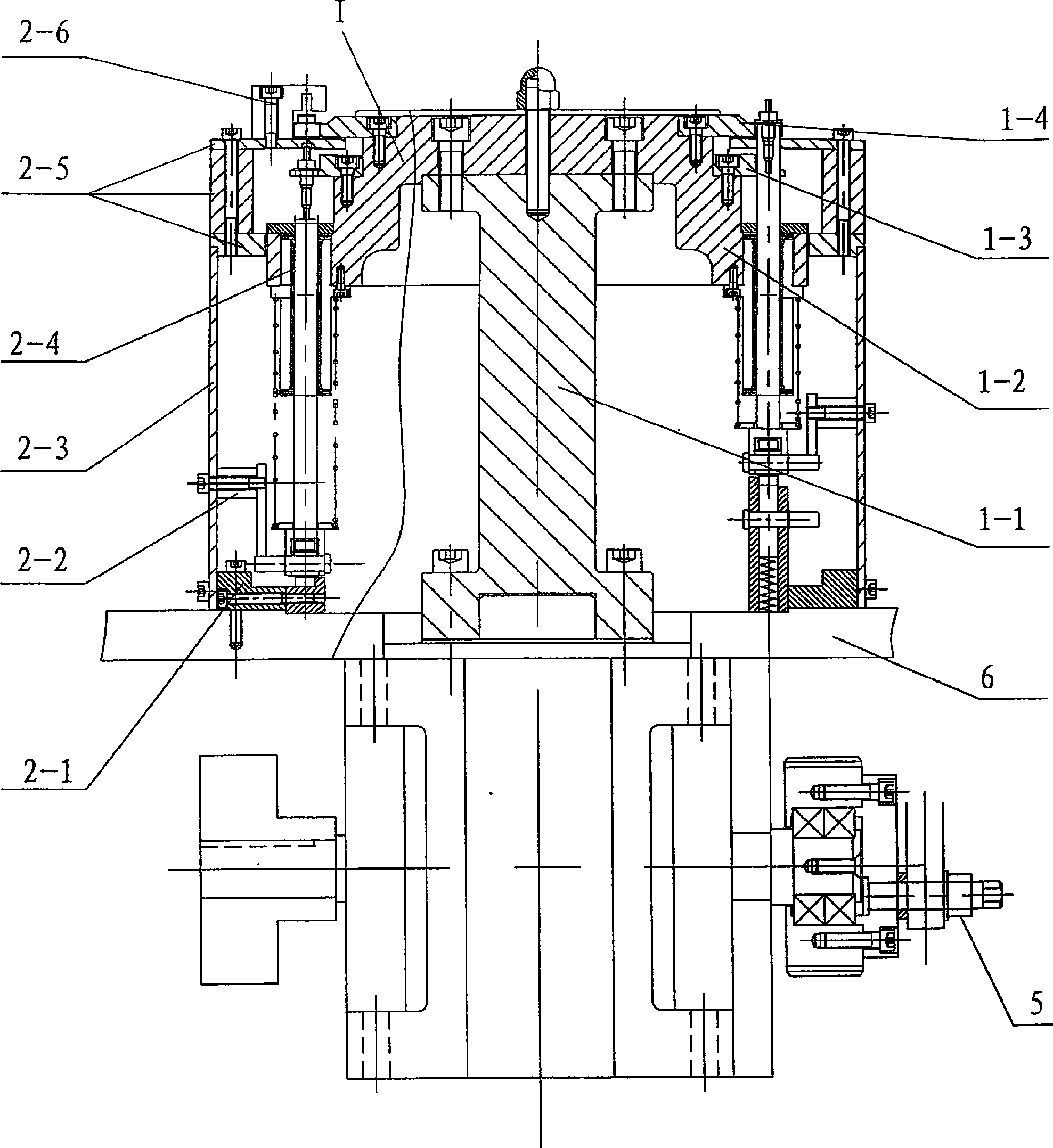

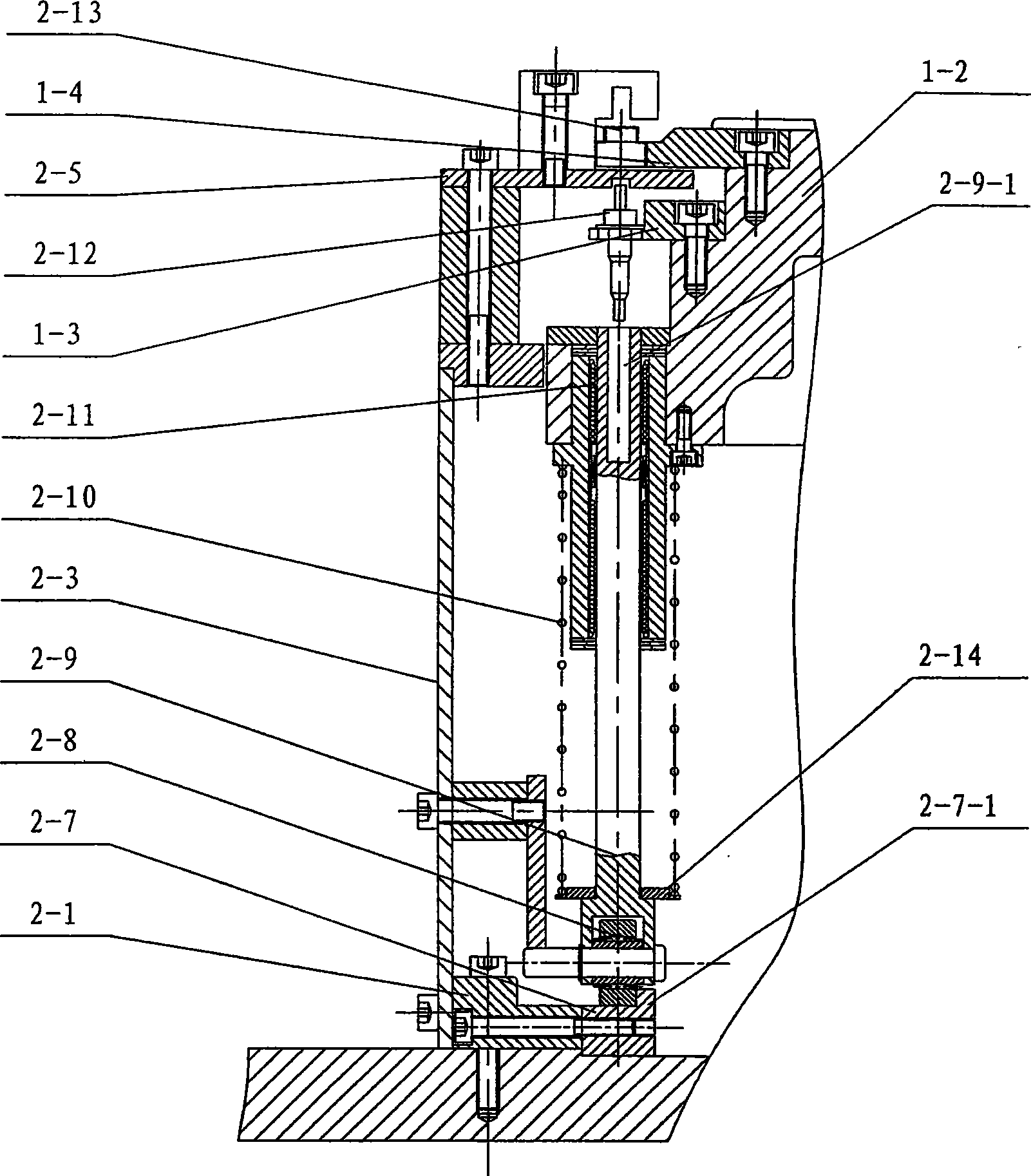

[0032] See figure 2 ~5, the turntable mechanism 1 is mounted on the machine base 6. It is mainly composed of a main shaft 1-1, a turntable seat 1-2, an anodized aluminum shell turntable 1-4 and a pump body turntable 1-3. The main shaft 1-1 is vertically upwardly mounted in the middle of the top surface of the base 6, the lower end of the main shaft 1-1 is connected to an output end of the divider mechanism 5, and the turntable base 1-2 is fixedly connected to the main shaft 1-1. At the upper end, the pump body turntable 1-3 and the anodized aluminum shell turntable 1-4 are arranged parallel to the outer edge of the turntable seat 1-2, and the pump body turntable 1-3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com