Multi-arrangement label supporting table lifting feeding and label conveying mechanical arm

A technology of manipulators and labels, applied in the field of manipulators, can solve problems such as difficulty in meeting processing requirements, poor stability and synergy, and large label limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

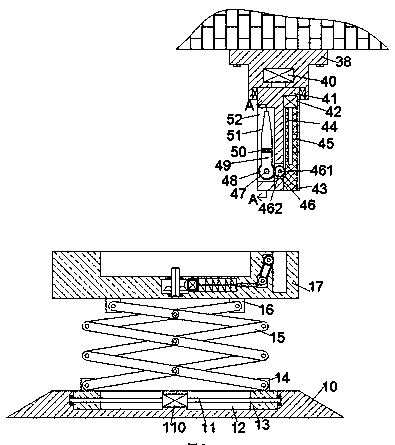

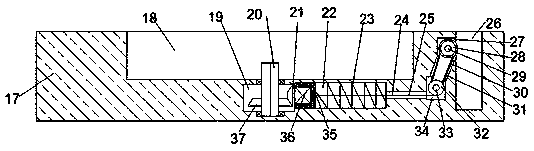

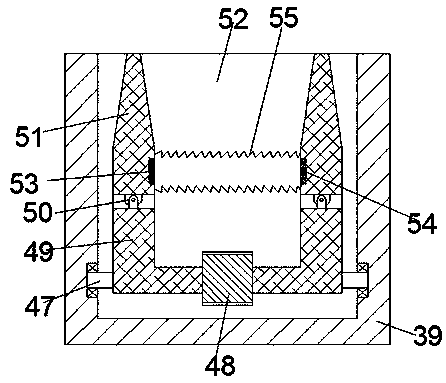

[0017] Such as Figure 1-4 As shown, a multi-arrangement label pallet lifting feeding and label conveying manipulator of the present invention includes a label table 60, a base 10 set on the base 10 through a lifting device, and a pallet 17 set on the pallet. 17 above the manipulator device, the bracket 17 is provided with an installation groove 18 with an upward opening, and the inner bottom wall of the installation groove 18 is provided with a first rotating chamber 19, and the inner bottom wall of the first rotating chamber 19 is rotated and installed There is a spline shaft 20 extending into the installation groove 18, a first bevel gear 37 is fixed on the spline shaft 20 in the first rotating chamber 19, and the right inner wall of the first rotating chamber 19 There is a first slide groove 22 extending to the right in the center, and a first slide block 35 is slidably installed in the first slide groove 22, and a first motor 36 is fixed inside the left end surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com