Automatic bonding equipment for rubber strip

An automatic bonding and rubber strip technology, which is applied in the field of automatic robotic arms, can solve the problems of difficulty in ensuring efficiency and the dependence of bonding yield on manual proficiency, so as to ensure product uniformity, improve operating process efficiency, and gripping accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific drawings and embodiments.

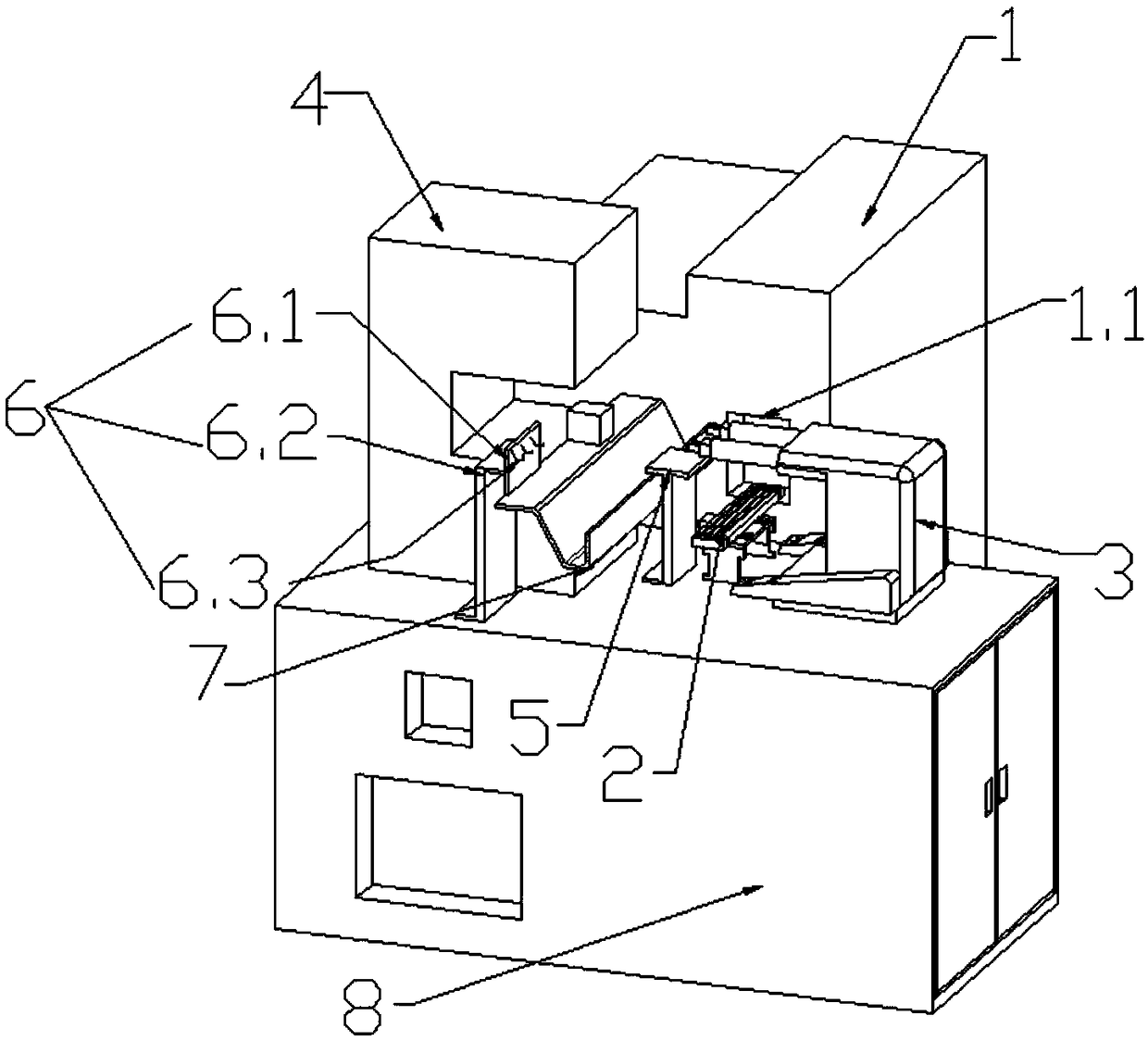

[0027] Such as Figure 1-5 Shown: The equipment is fully enclosed to ensure personal safety; when material needs to be taken, the door can be opened to take material (the equipment stops running when the door is opened).

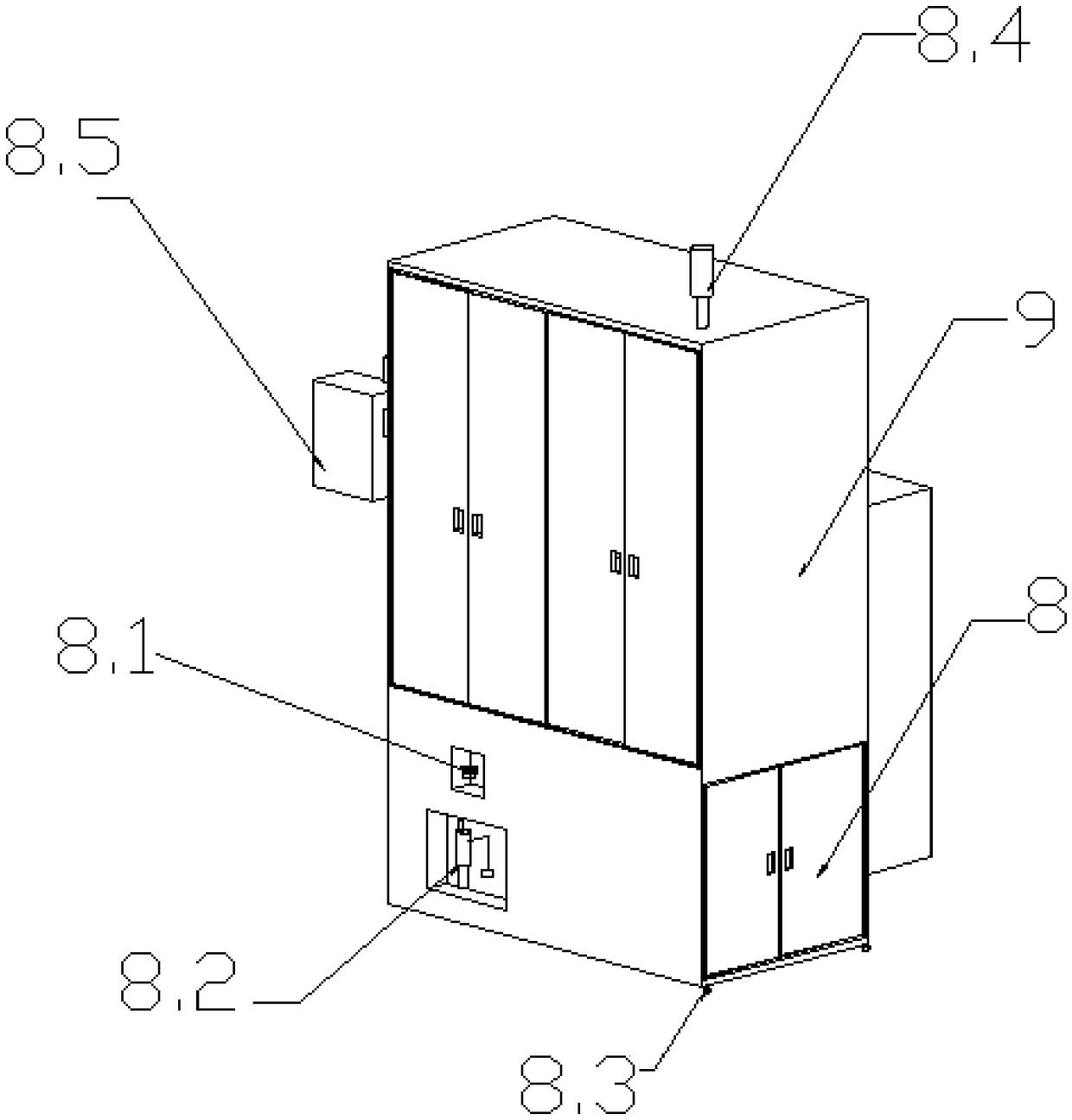

[0028] A rubber strip automatic bonding equipment is characterized in that it includes a control seat 8 and an operation cabinet 9;

[0029] The control seat 8 is arranged at the bottom of the operation cabinet 9;

[0030] Adhesive strip bonding parts are arranged in the operation cabinet, and a drive control device is arranged in the control seat;

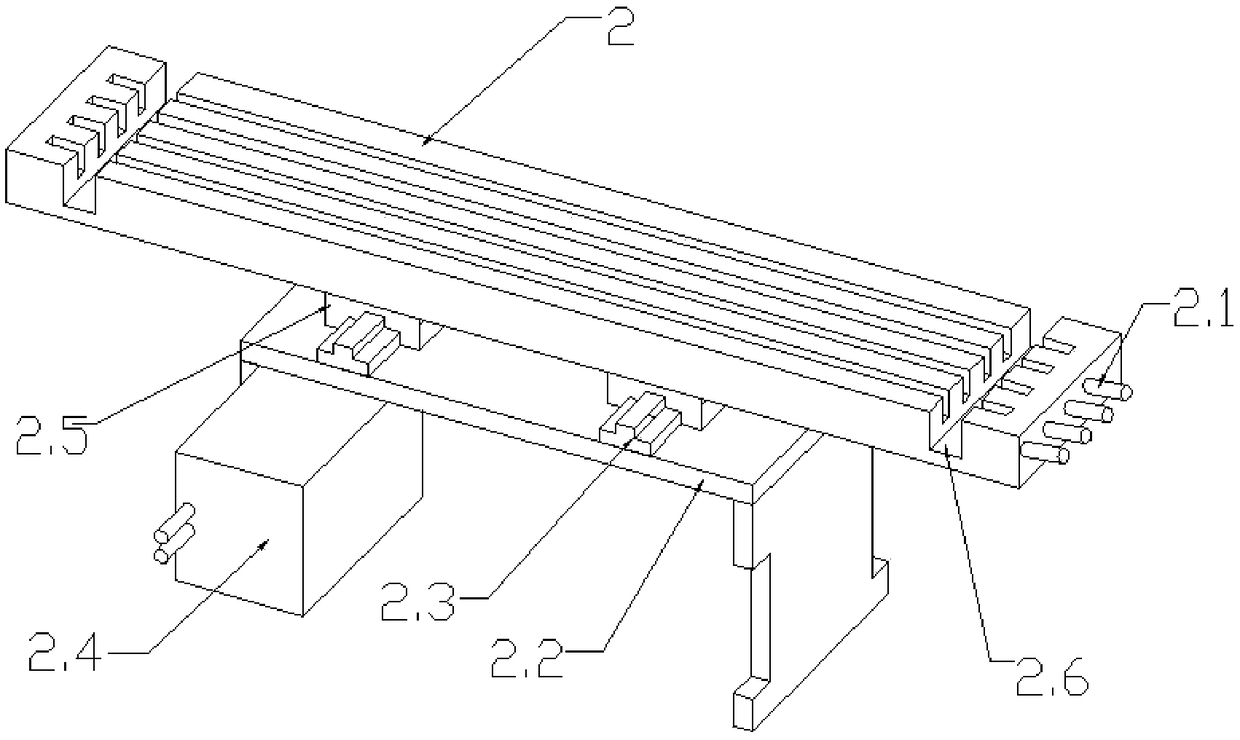

[0031] The glue strip bonding parts include glue strip cutting equipment 1, glue strip positioning groove plate 2, mechanical arm assembly 3, glue strip hot pressing equipment 4, glue platform 5, wire hanger 6 and wire support tray 7;

[0032] The rubber strip hot-pressing equipment 4 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com