Pulling tool

A tool and workpiece technology, applied in the field of pulling tools, can solve the problems of low successful separation rate, influence analysis results, high labor intensity, etc., to reduce labor intensity, avoid ring damage, and improve accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

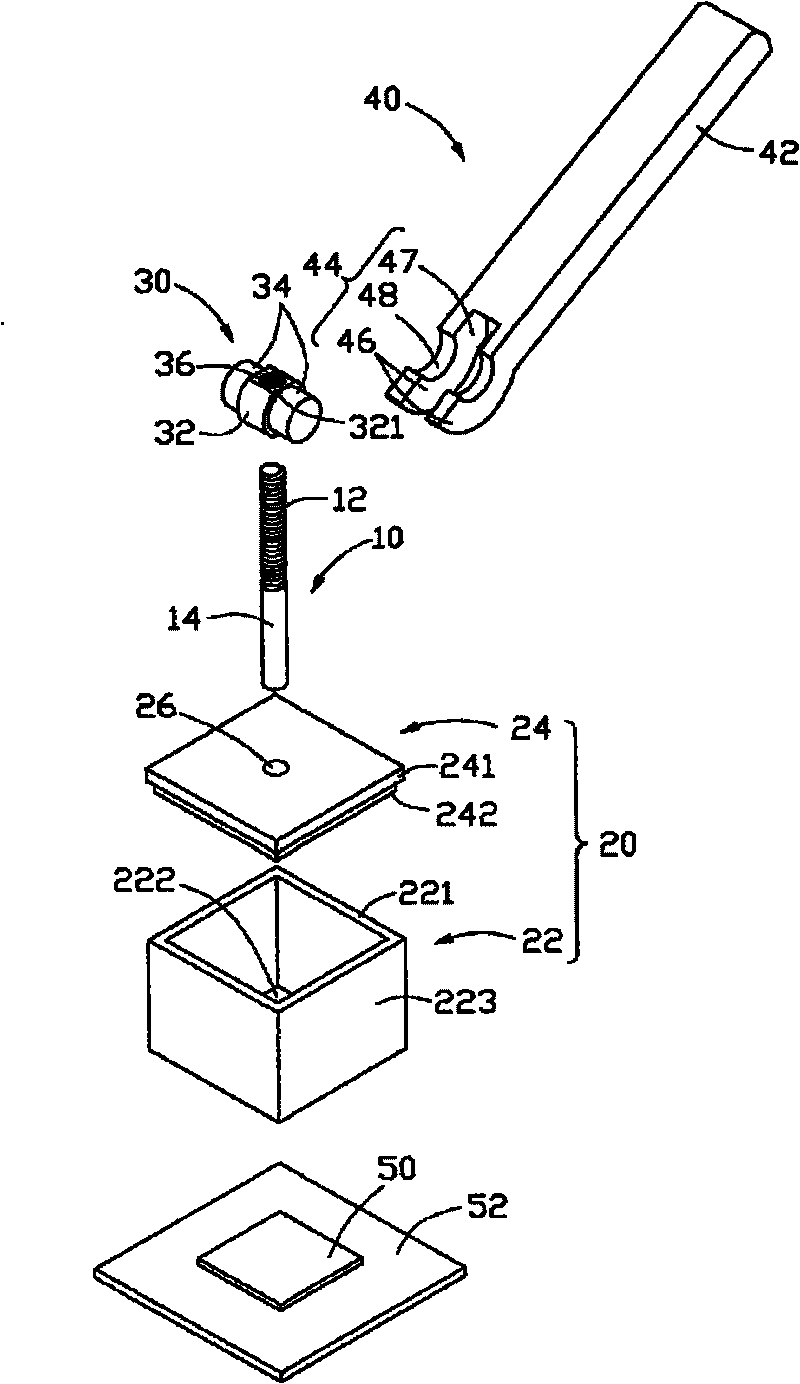

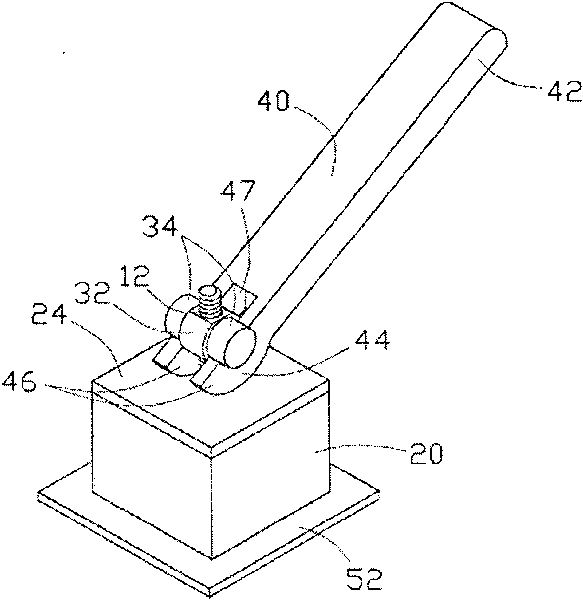

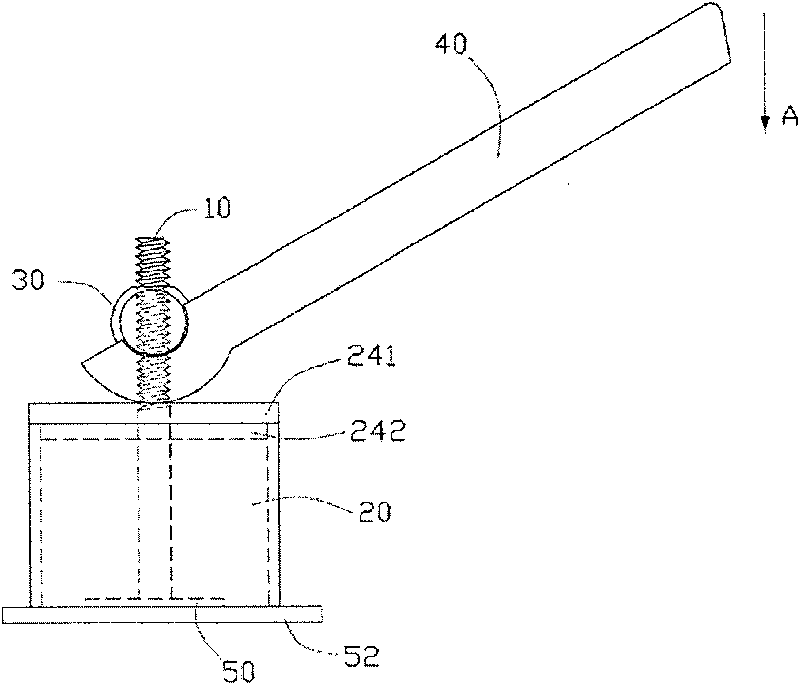

[0011] Please refer to figure 1 , the preferred embodiment of the pulling tool of the present invention is used to separate the BGA part 50 from the PCB board 52, which includes a pulling rod 10, a support seat 20 for fixing the pulling rod 10, and a The rotating shaft 30 on the pulling rod 10 and a wrench 40 engaged on the rotating shaft 30 .

[0012] The pulling rod 10 is a long round rod, one end of which is a threaded portion 12 and the other end is a free end 14 . The end face of the free end 14 is bonded to the BGA piece 50 by AB colloid and lime.

[0013] The support base 20 includes a box body 22 and a cover plate 24 covering the box body 22 . The box body 22 is a square cylinder, including four side walls 223 connected end to end and an upper edge 221 , and a cavity 222 is formed around the side walls 223 . The cover 24 includes an integrally formed covering portion 241 and a matching portion 242 extending from the bottom of the covering portion 241 . The matching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com