Regulating mechanism for working gap

A technology for working gaps and adjusting mechanisms, which is applied to power transmission devices, printing, transfer materials, etc., can solve the problems of difficult maintenance, complex structure of adjusting mechanisms, and high production costs, and achieves simplified main structure of guide shafts, which is beneficial to Use the effects of maintenance and difficulty reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

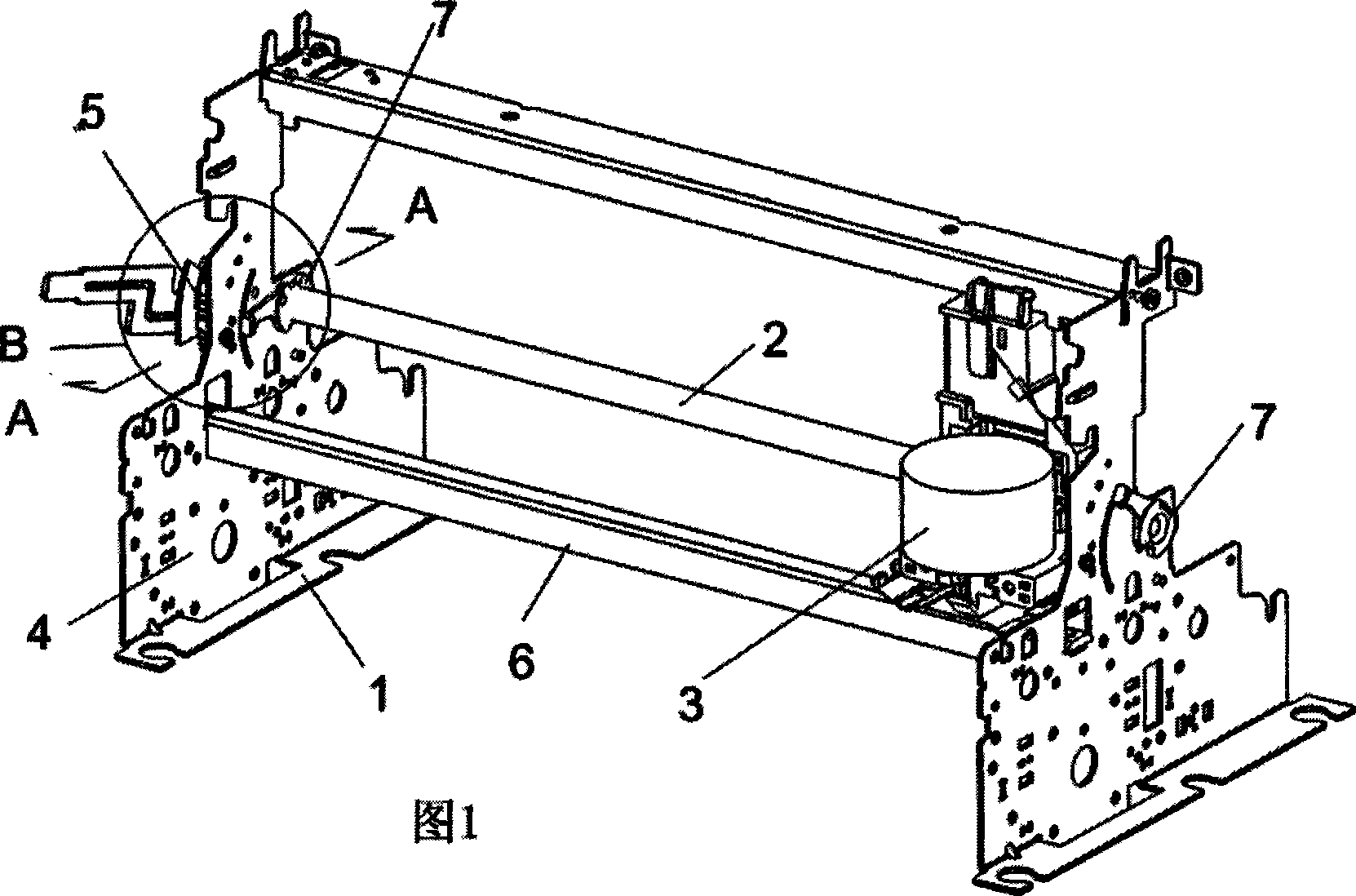

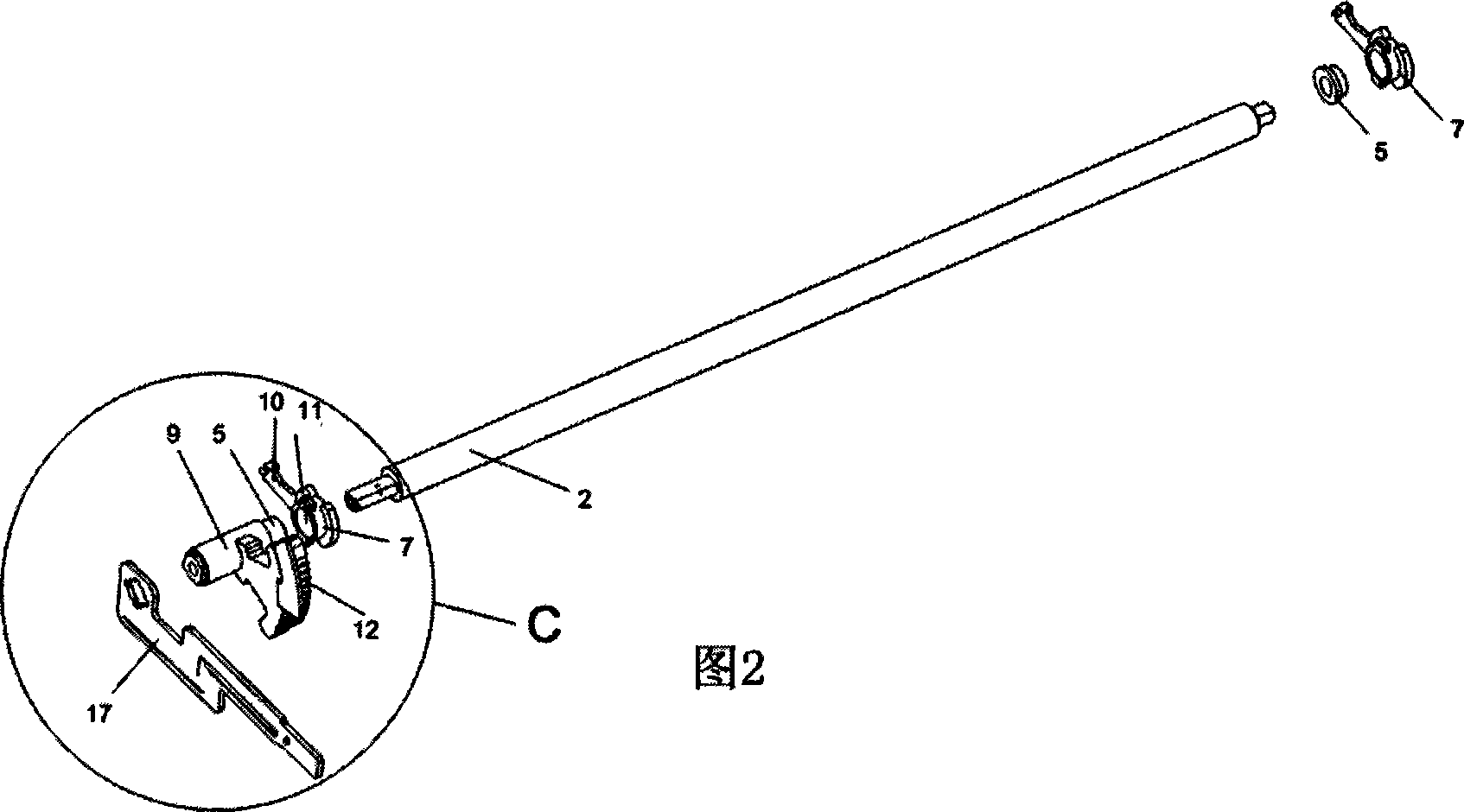

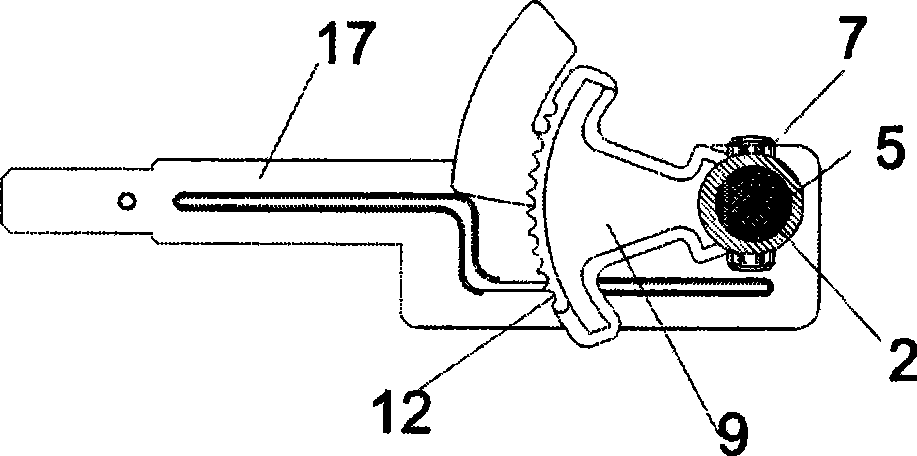

[0013] As shown in Figure 1, the present invention comprises the working end guide shaft 2 that is arranged on the frame 1 horizontally, the working end head 3 (such as printing head) that can slide laterally along the guide shaft and the support that is located at both sides of the frame The seat 4 is characterized in that a pair of eccentric circular shaft sleeves 5 are arranged on the support seats 4 on both sides and are fixedly connected to both ends of the guide shaft 2, so that the eccentric circular shaft sleeves can drive the guide shaft 2 and the working end when rotating. The head 3 (such as the printing head) is adjusted for the upper and lower gaps relative to the working plane of the frame (such as the printing plate 6).

[0014] In order to realize the parallelism adjustment of the working ends, the outer circumferences of the above-mentioned pair of eccentric circular shaft sleeves 5 are respectively connected in rotation with the bearing holes 8 of the supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com