Two-faced adhesive tape

A double-sided adhesive tape and adhesive layer technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of dragging glue, polluting the surface of paper or objects, and poor positioning of gluing positions, etc., to ensure that Neat and clean, overcome the effect of dragging and drawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

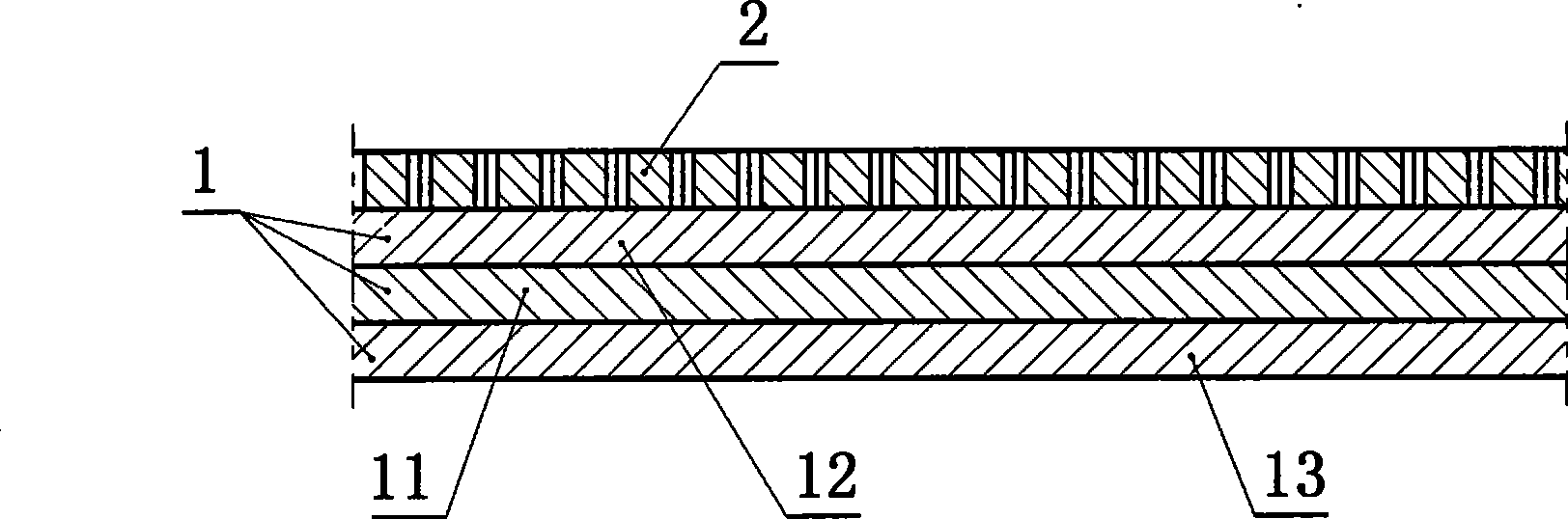

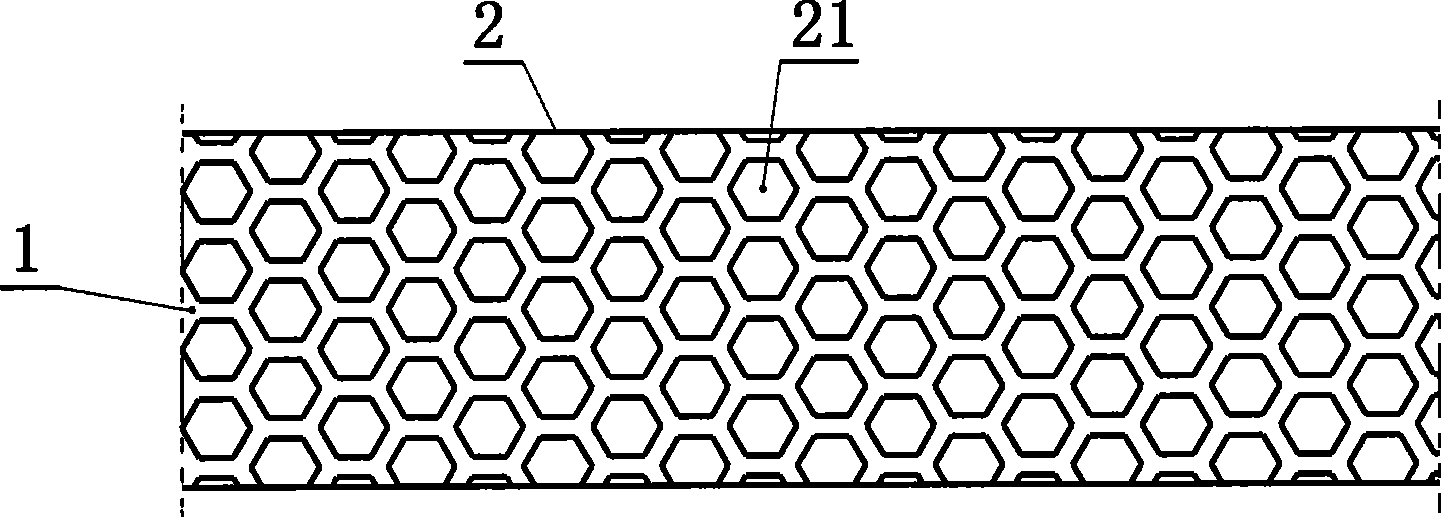

[0016] Embodiment 1: see Figure 1 ~ Figure 2 As shown, the double-sided adhesive tape of the present invention comprises the release paper that adopts the belt substrate layer 11 of plastic film or fiber paper tape and the upper release layer 12 and the lower release layer 13 that are coated and connected on its upper and lower surfaces Layer 1, the upper surface of the release paper layer 1 is coated and connected with an adhesive layer 2, the above is the prior art, and its distinguishing feature is that: the upper surface of the release paper layer 1 is coated with a connected adhesive layer 2. It is composed of hexagonal pressure-sensitive adhesive dots 21 with the same thickness and equidistant distribution. The thickness of the pressure-sensitive adhesive dots 21 is selected within the range of 0.01-0.1 mm, and the size of the side length is selected within the range of 0.25-1 mm. , the distance between the periphery of each pressure-sensitive adhesive dot 21 is selecte...

Embodiment 2

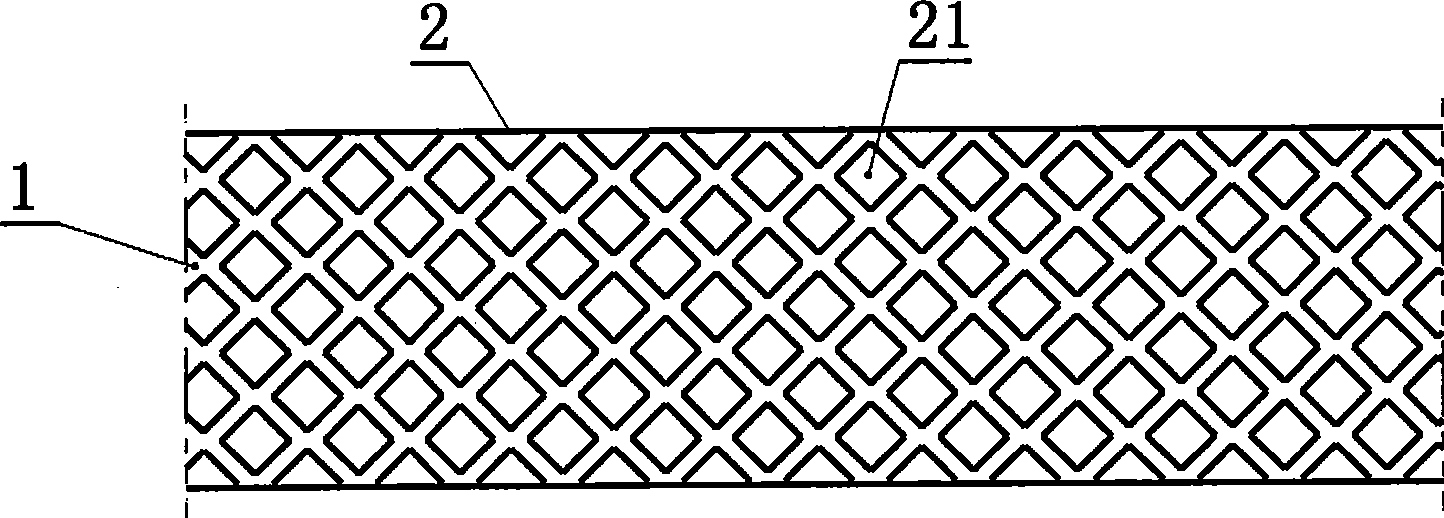

[0018] Example 2: see image 3 As shown: the adhesive layer 2 coated and connected to the upper surface of the release paper layer 1 is composed of square pressure-sensitive adhesive dots 21 arranged equidistantly with the same thickness, and the thickness of the pressure-sensitive adhesive dots 21 is between 0.01 and Choose within the range of 0.1 mm, choose the side length of the size within the range of 0.8-2 mm, and select the distance between the periphery of each pressure-sensitive adhesive point 21 within the range of 0.2-0.8 mm.

Embodiment 3

[0019] Embodiment 3: see Figure 4 As shown: the upper surface of the release paper layer 1 is coated and connected with the adhesive layer 2, which is composed of equidistant triangular pressure-sensitive adhesive dots 21 with the same thickness, and the thickness of the pressure-sensitive adhesive dots 21 is 0.01 Choose within the range of ~0.1mm, choose the size of the side length of the equilateral triangle within the range of 0.8~2mm, and choose the distance between the periphery of each pressure-sensitive adhesive point 21 within the range of 0.2~0.8mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com