Oil pipe filter for steam turbine and gas turbine

A technology for gas turbines and oil pipes, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve problems such as difficulty in ensuring effective sealing, increased operating costs of power plants, and blockage of filter cloth filter holes, etc., and achieves a simple structure , reduce operating costs, and facilitate cleaning of the filter element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

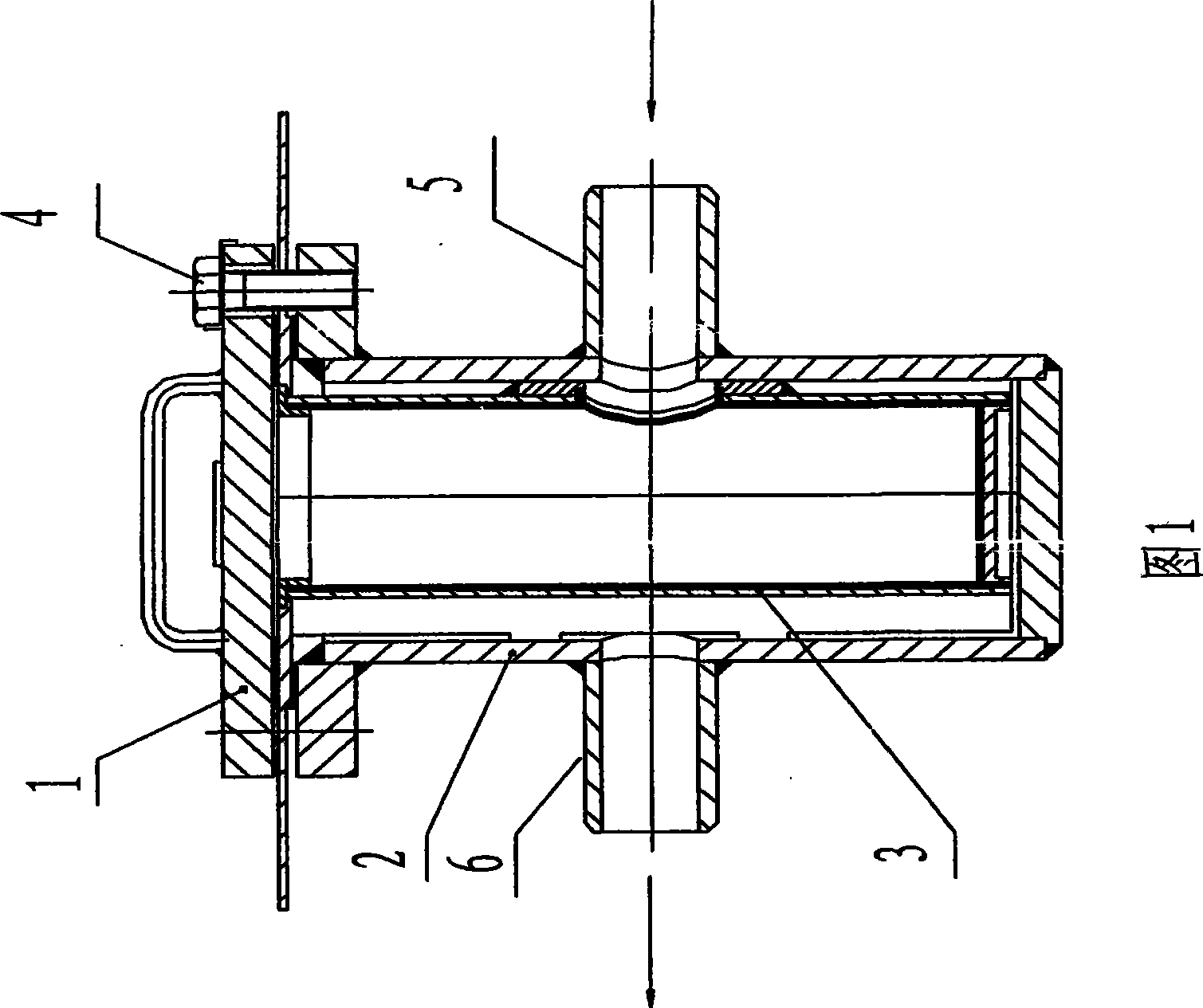

[0020] See Figure 1: This filter is composed of cover plate 1, housing 2 and filter element 3. The filter element 3 is arranged in the housing 2, and the upper opening is covered by the cover plate 1, and the cover plate 1, Housing 2 is fastened. The waist of the housing 2 is provided with an oil inlet 5 and an oil outlet 6 .

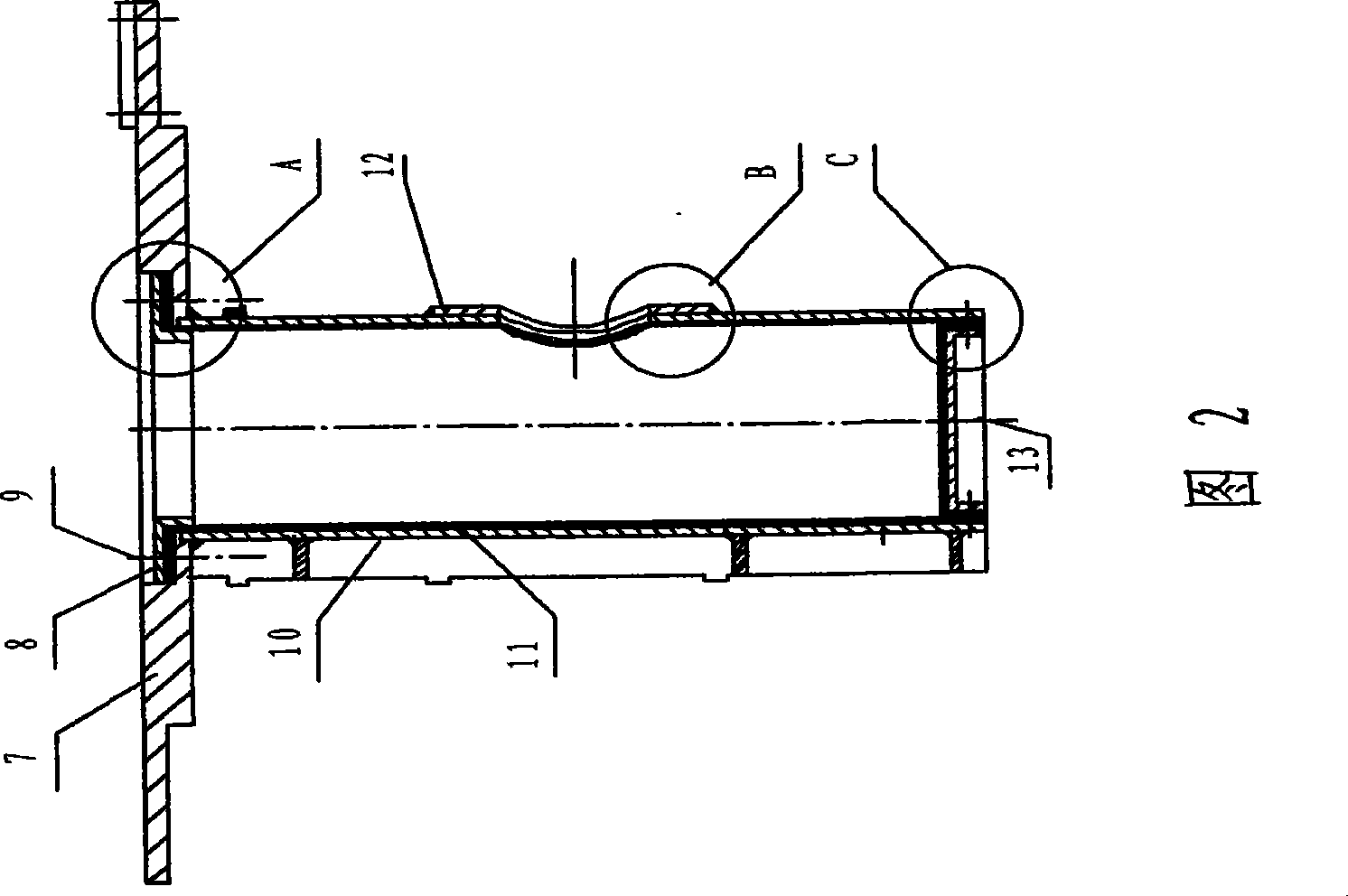

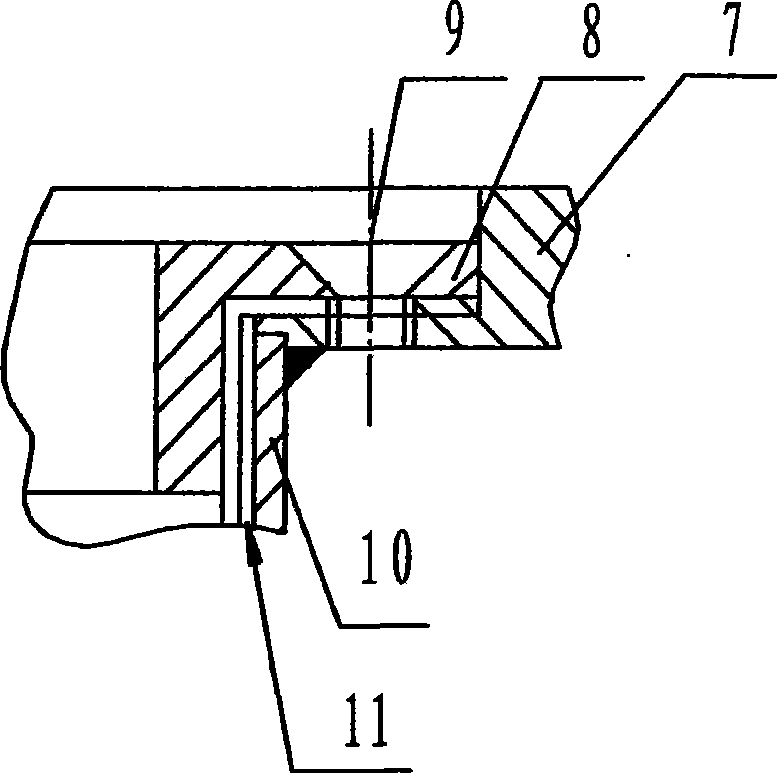

[0021] The present invention mainly improves the structure of the filter element 3, see Fig. 2: the filter element 3 includes a cylindrical filter frame 10, the upper end of the filter frame 10 has a flange 7, the lower end has a bottom plate 13, and the waist is opened with an inlet. Oil port, oil inlet periphery is welded with reinforcing ring 12. The center hole of the flange 7 has a stepped seam. The periphery of the bottom plate 13 is turned down, so that the bottom plate 13 is in the shape of an upside-down disc, and the circumferential dimension is adapted to the inner cavity of the framework 10 . The filter screen frame 10 is to be coiled and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com