Visual observation and transient measurement method and apparatus for cooling process of turbine blade

A technology of turbine blade and cooling process, applied in the field of devices for realizing the above method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

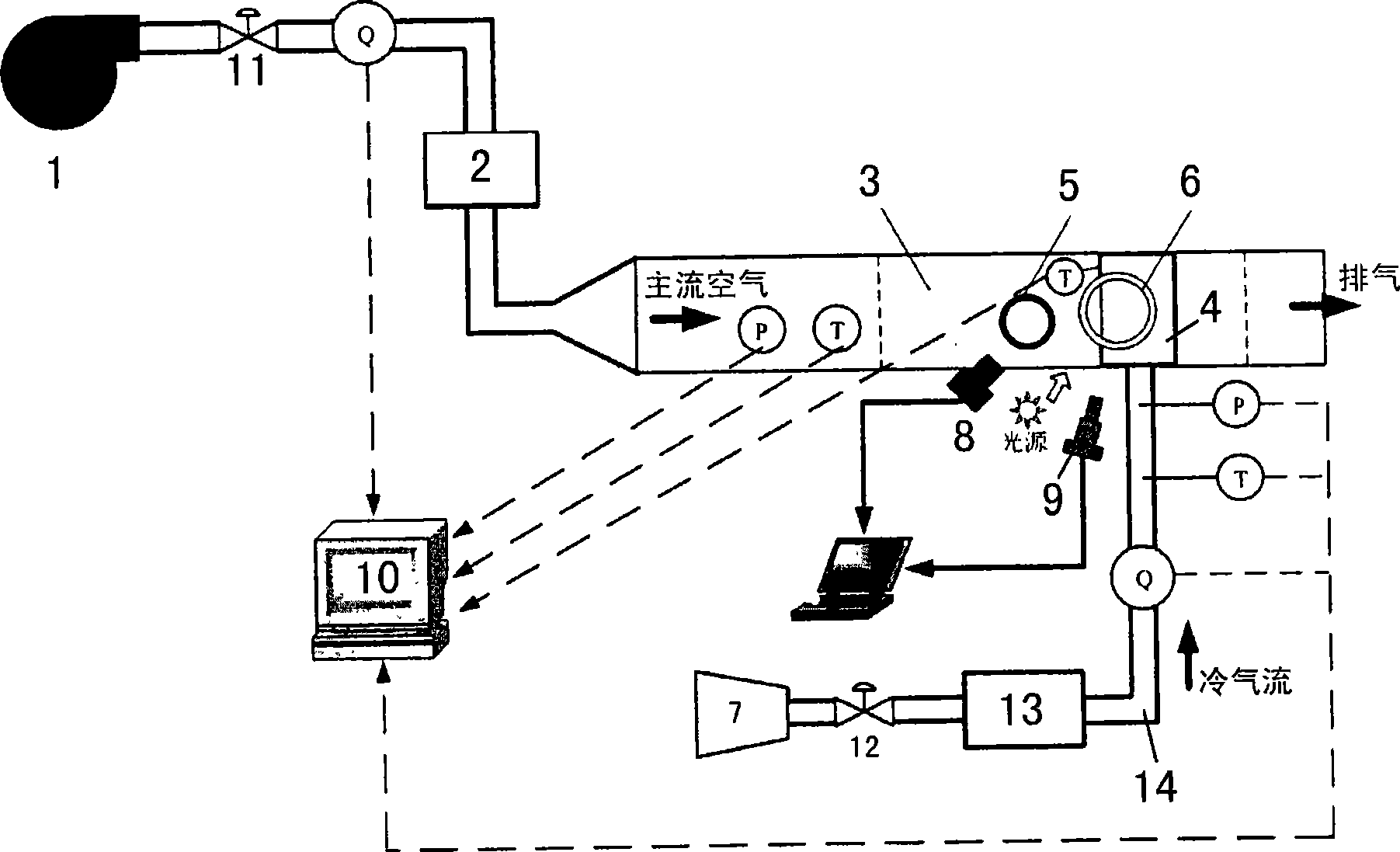

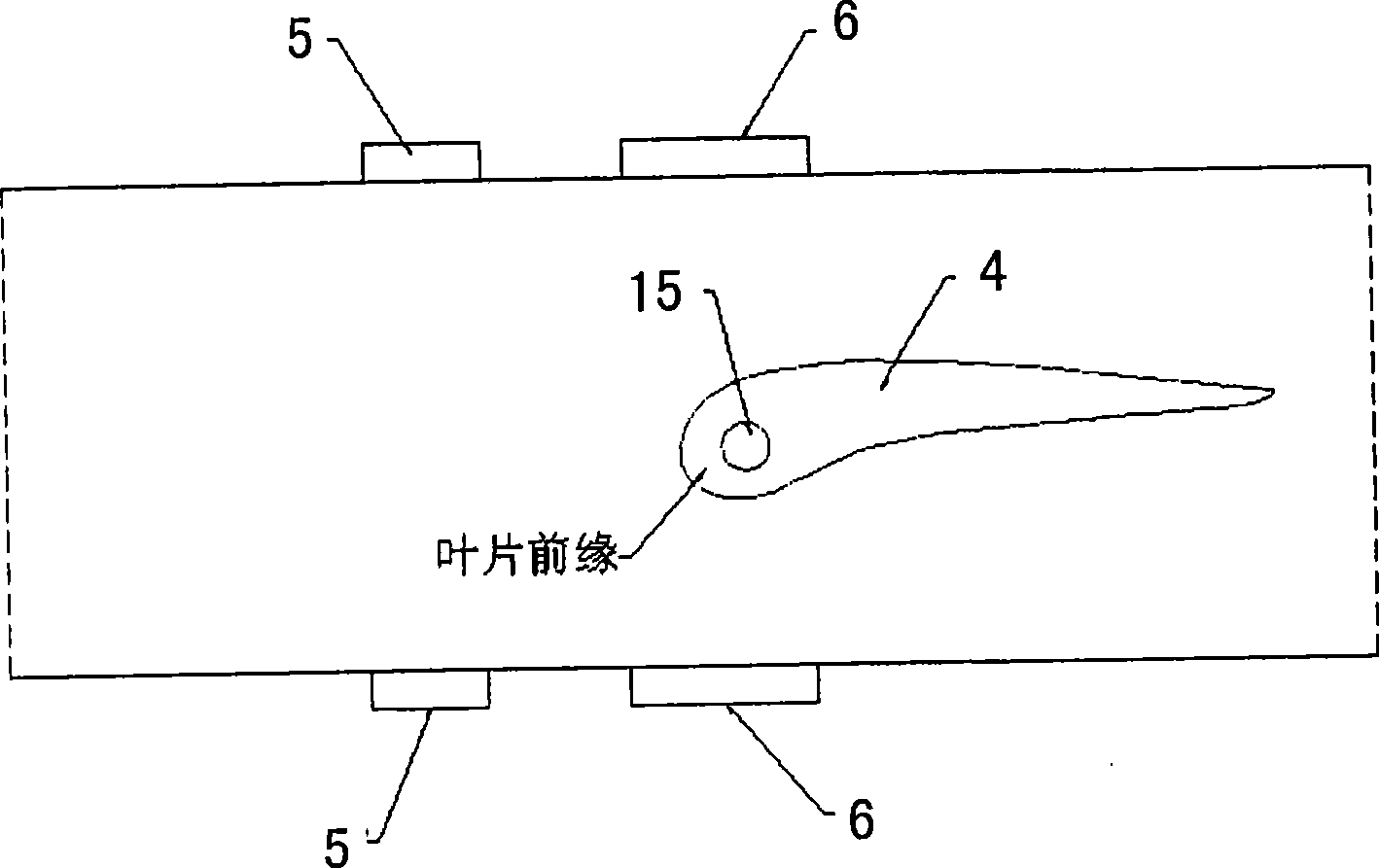

[0032] see figure 1 and figure 2 , is a schematic diagram of the testing device of the present invention.

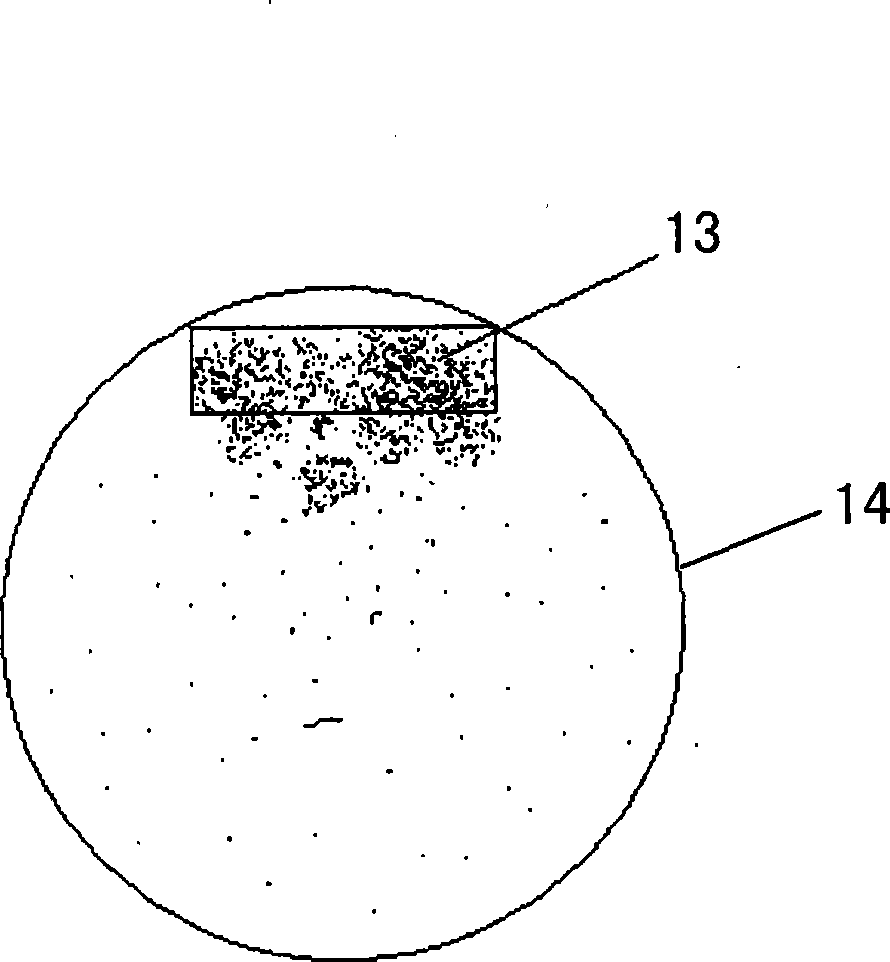

[0033] The present invention mainly consists of a blower 1, a heater 2, a wind tunnel 3, a turbine blade 4, an infrared detection window 5, a visual observation window 6, an air compressor 7, an infrared thermal imager 8, a microscopic magnifying photographic device 9, temperature and pressure And flow measurement and data acquisition and recording device 10, flow regulating valves 11 and 12, paint adding device 13 and cold air pipe 14.

[0034] Among them, the flow rate of blower 1 is 0-850m 3 / h is adjustable; the heater 2 is electric heating, and the power is adjustable from 0-3000W. By adjusting the power of the heater, the temperature of the mainstream hot air can be adjusted within the range of 20-500°C.

[0035] The wind tunnel 3 is a cuboid made of stainless steel with a length of 3500mm and a section of 100×100mm. One end of the wind tunnel 3 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com