Surface quality on-line detection system for coin finished goods

A technology of surface quality and detection system, which is applied in the direction of optical testing for flaws/defects, etc., can solve the problems of high rate of waste leakage and false waste, the inability to realize real-time control of continuous waste products, and the inability to accurately capture coin feature defects, so as to reduce false waste high efficiency, easy capture, improved accuracy and labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

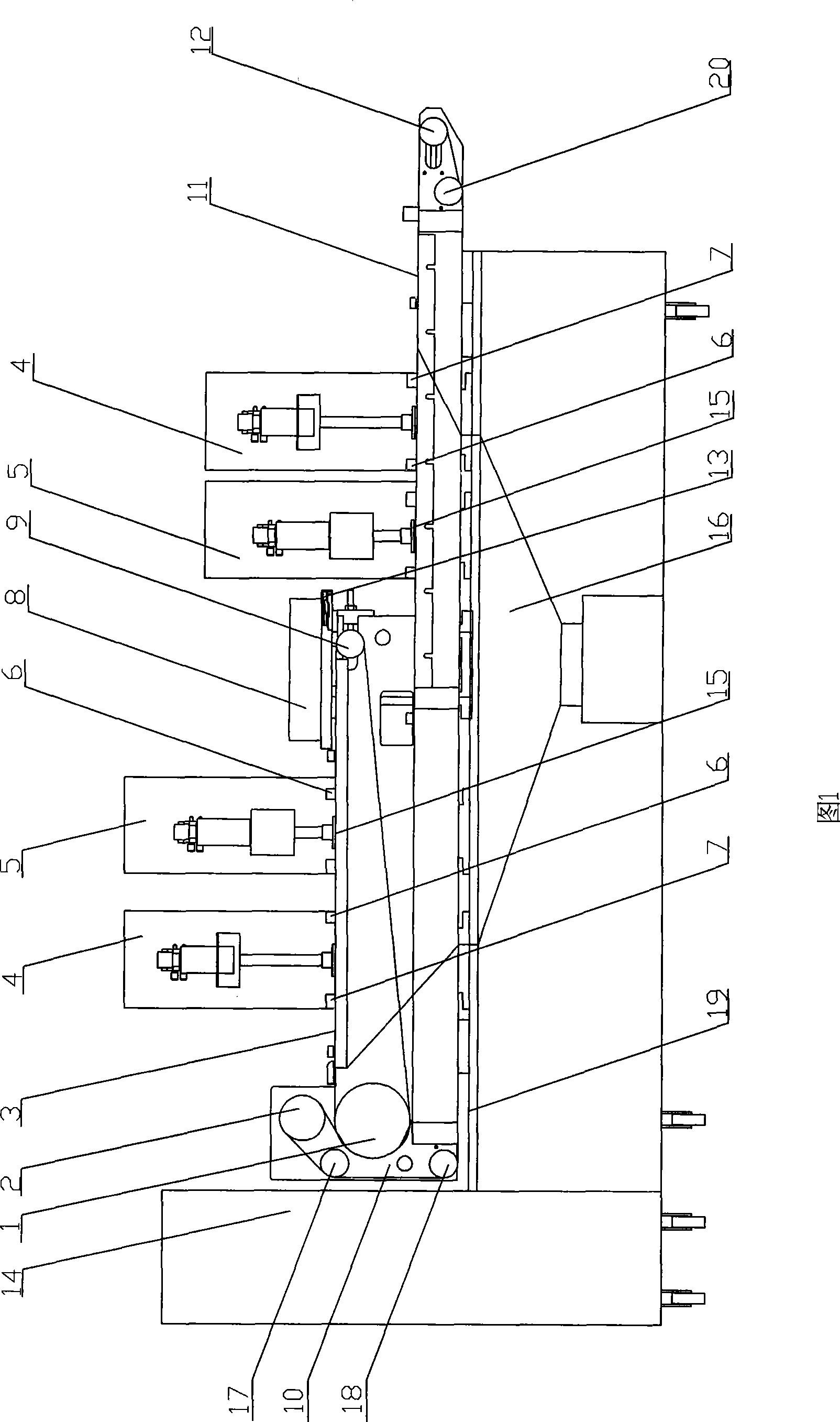

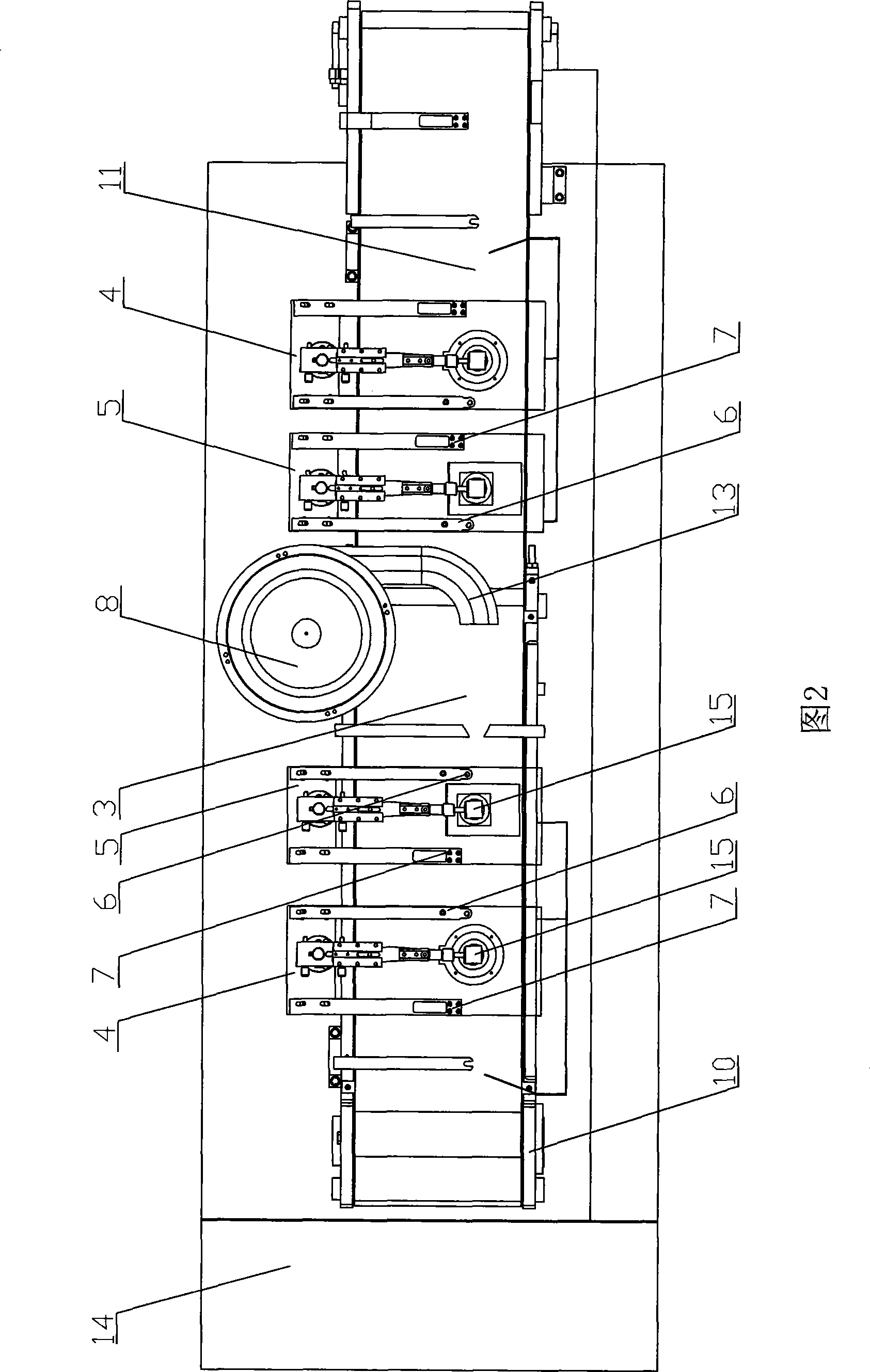

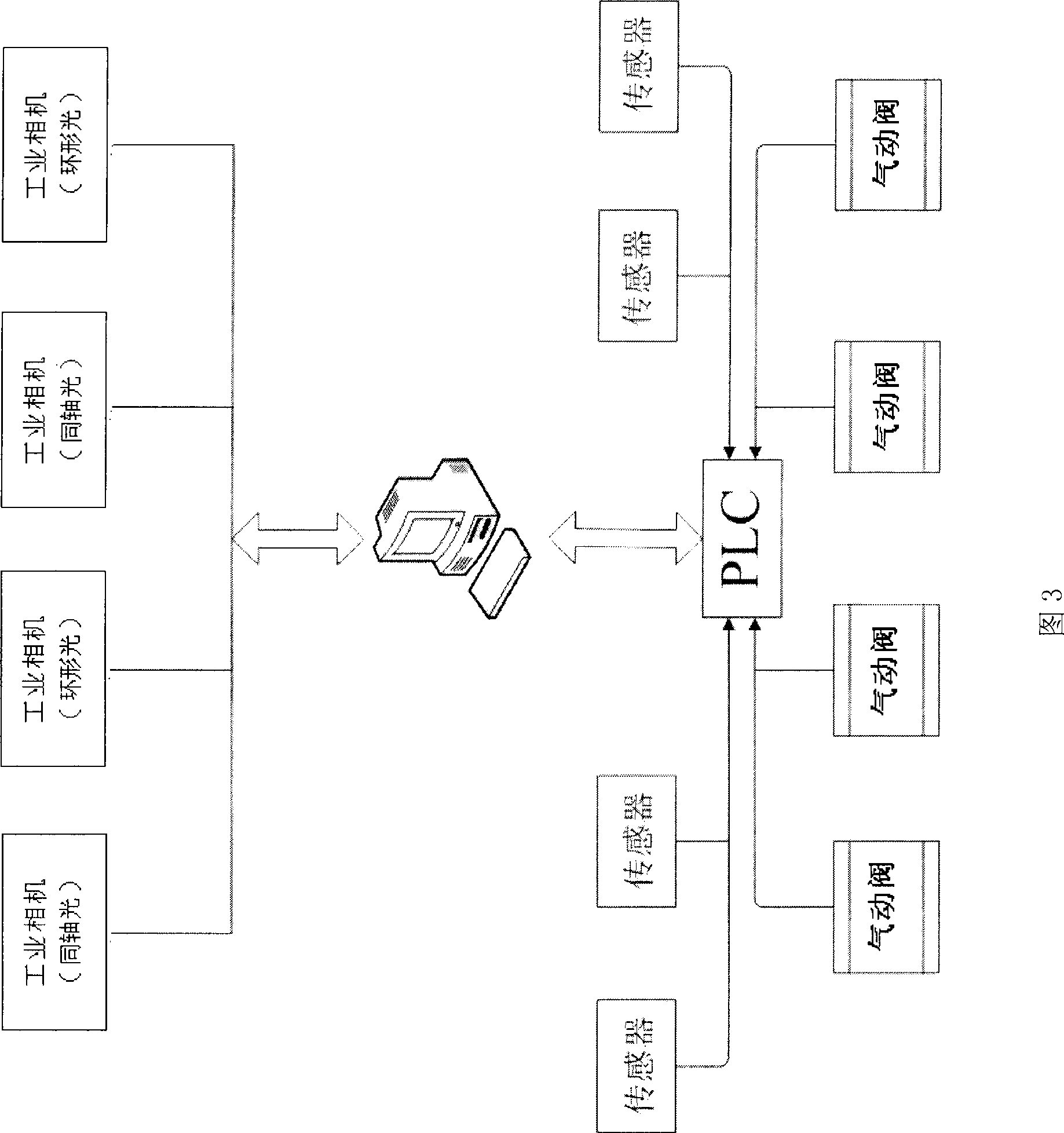

[0019] Referring to accompanying drawing 1~2, the present invention is constituted the transmission belt 3 of " O " shape loop by the large and small drive wheel 1,9 that is arranged on the frame 19, is formed C by drive wheel 2,12,17,18,20 The conveyer belt 11 of shape loop, the recess of C-shaped loop conveyer belt 11 is included in one end of " O " shape loop conveyer belt 3 and constitutes turning mechanism 10, and conveyer belt 3 one end is provided with centrifugal turntable 8, and the straight line of conveyer belt 3,11 A bright field detector 5 and a dark field detector 4 are arranged in turn on the conveying section, a slideway 13 is provided between the centrifugal turntable 8 and the conveyor belt 3, and a collection box for defective products is provided at the lower part of the conveyor belts 3 and 11 16. The programmable controller 14 is arranged on one side of the turning mechanism 10. The dark field detector 4 and the bright field detector 5 are composed of an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com