Coil inserting method and apparatus for electricity generator

A technology of embedding posts and clamping devices, applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of enameled wire knotting, affecting product quality, motor short circuit, etc., to prevent knots and facilitate wire embedding Operation, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the examples, but not as a limitation to the present invention.

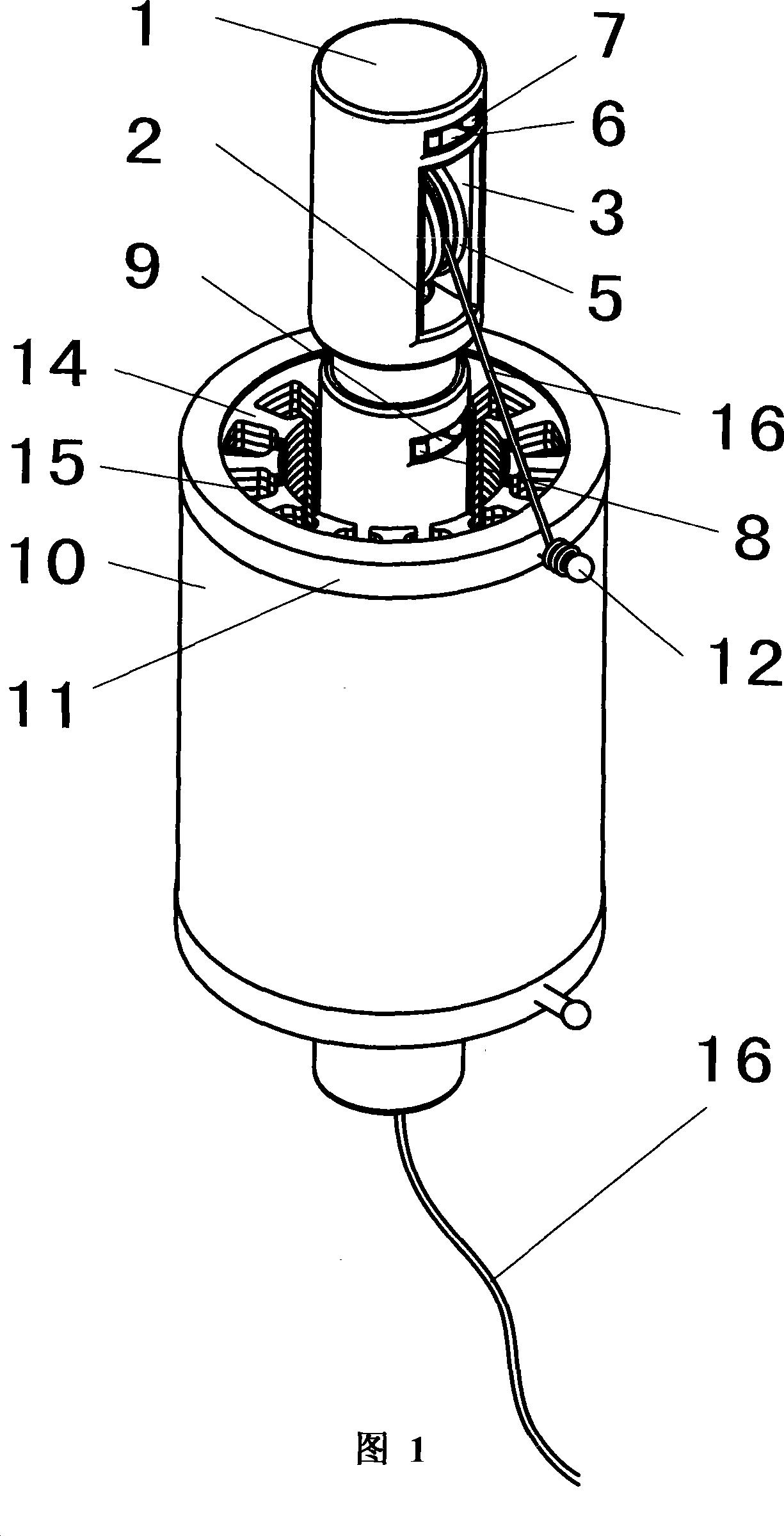

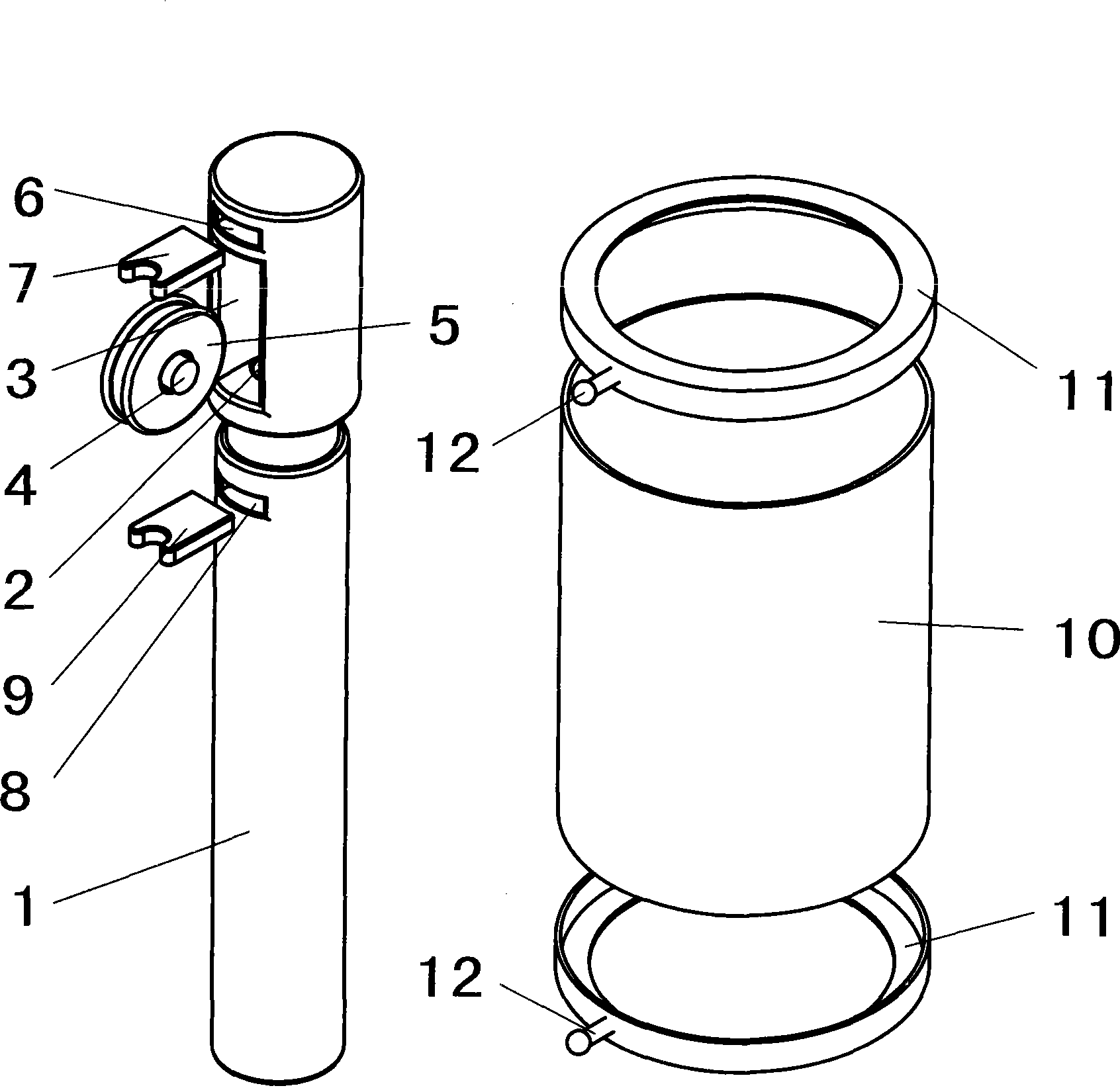

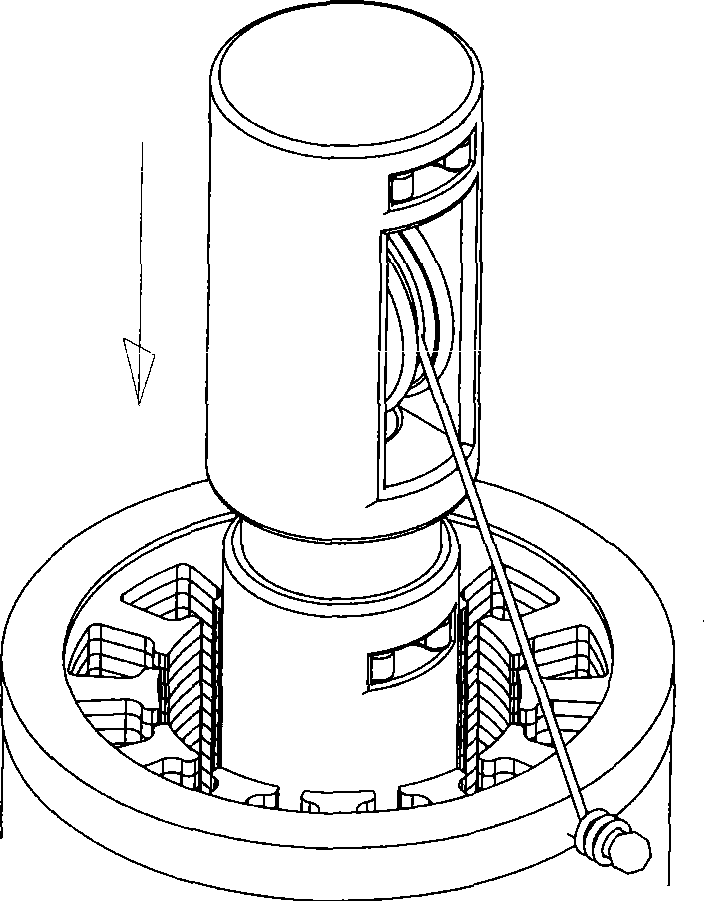

[0022] Embodiments of the invention. A motor wire embedding method, as shown in Figure 1, the method is to use a motor wire embedding device for embedding wire; the wire embedding device includes an iron core clamping device with upper and lower shrapnel and an embedding column, and the iron core The clamping device fixes the iron core, and the wire embedding column shuttles the enameled wire reciprocatingly outside the wire slot; every time the wire embedding post completes a stroke, the upper or lower shrapnel of the wire embedding post pushes the enameled wire into the wire slot of the wire slot; The core clamping device rotates to the next wire slot with the wire slot, and the wire insertion post returns from the next wire slot with the enameled wire; repeat the above operation until all the wire insertion of the stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com