Iwai makoto; shimodaira takanao; higashihara shuhei; sasaki takatomo; mori yusuke; kawamura fumio; yamasaki shiro; hirata koji

A technology of knitted fabrics and loops, which is applied in the field of knitted fabrics, can solve the problems of increased yarn burden and loop stripping, and achieve the effect of small burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

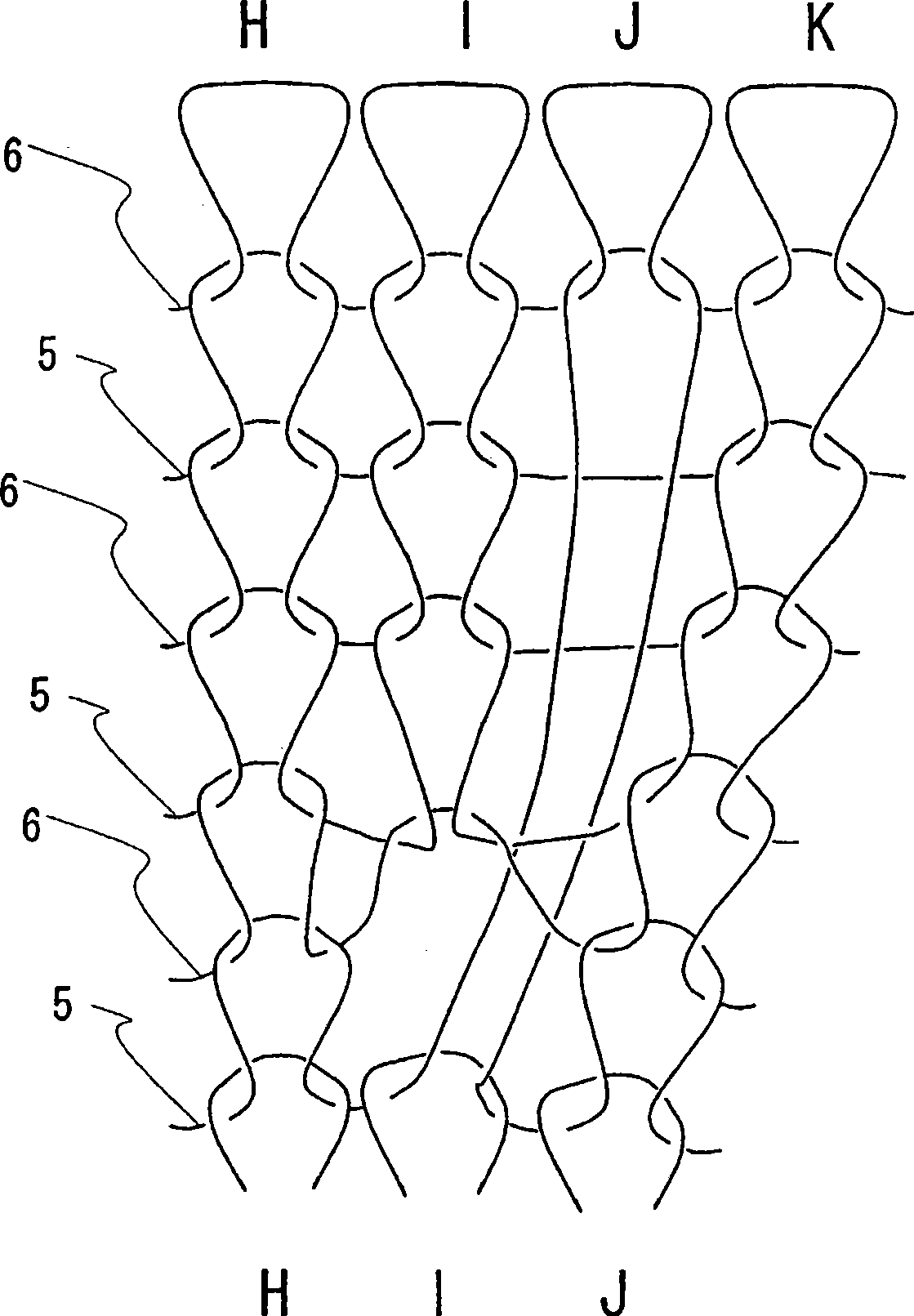

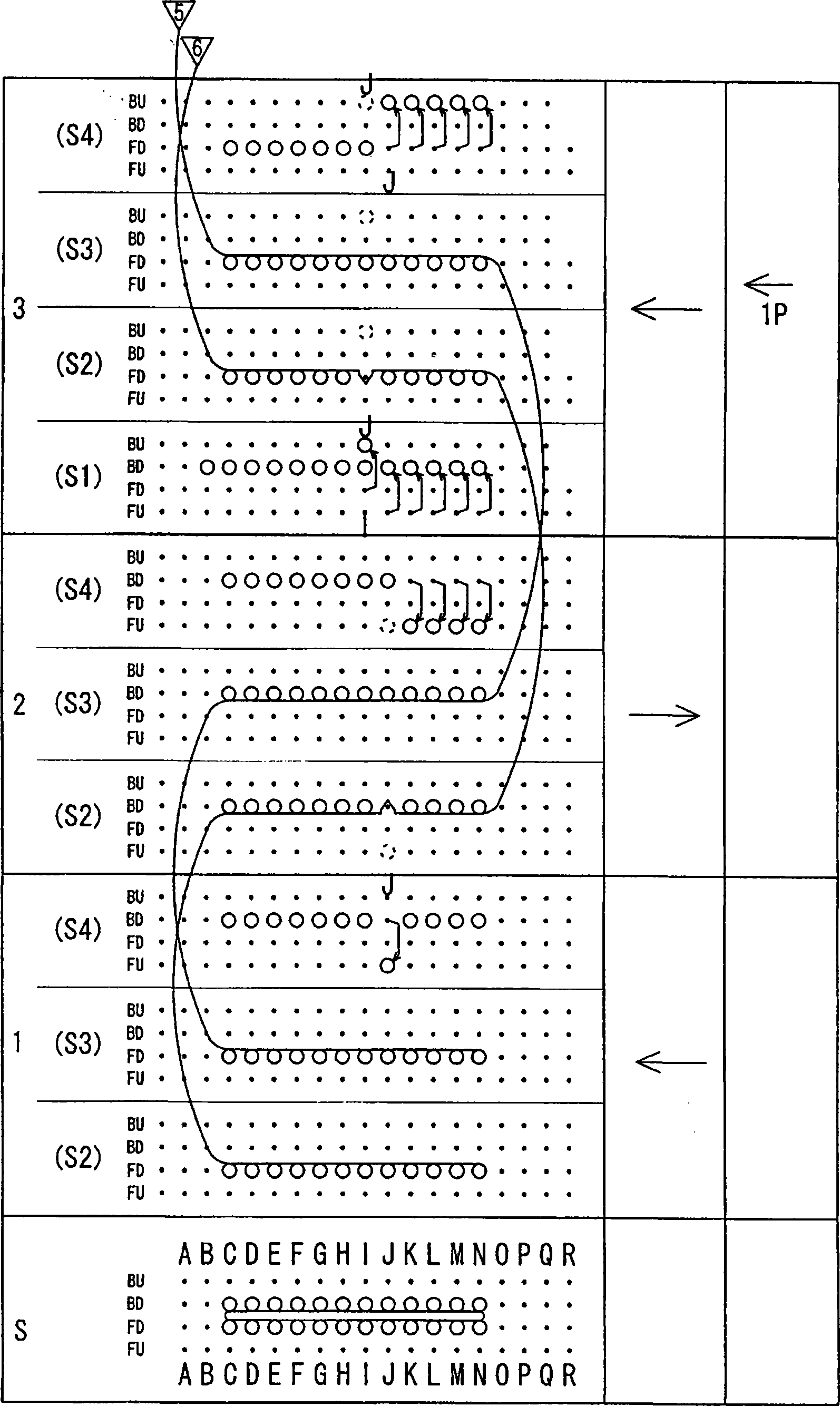

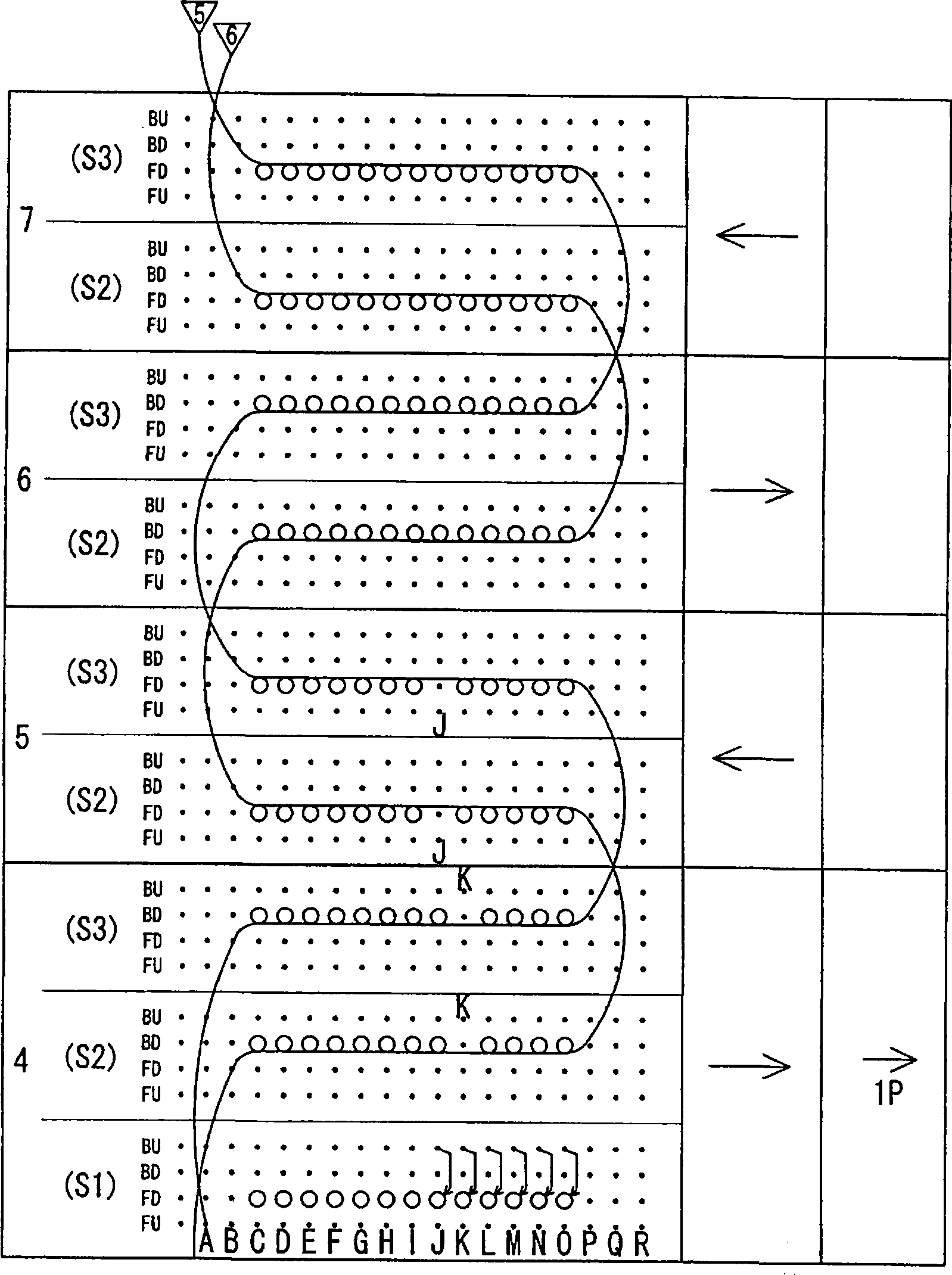

[0049] Next, preferred embodiments of the present invention will be described in detail with reference to the drawings. In this embodiment, the knitted fabric is knitted using a 4-needle-bed flat knitting machine having a pair of front and rear needle beds extending in the left-right direction and facing each other in the front-rear direction, the rear needle beds can traverse left and right, and can The stitches are transferred between the front and rear needle beds.

[0050] When knitting knitted fabrics, it is also possible to knit using a flat knitting machine with two needle beds consisting of a front needle bed and a rear needle bed. In the case of knitting a knitted fabric using a flat knitting machine with two needle beds, the knitted fabric is knitted with empty needles provided every other. In addition, when using a flat knitting machine with two needle beds, a transfer bed needle bed may be provided on one or both of the front and rear needle beds to knit the knitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com