Improved unwinding coiler

A technology of uncoiler and machine base, which is applied in the field of cold roll forming machine equipment, and can solve problems such as slow unwinding and rewinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

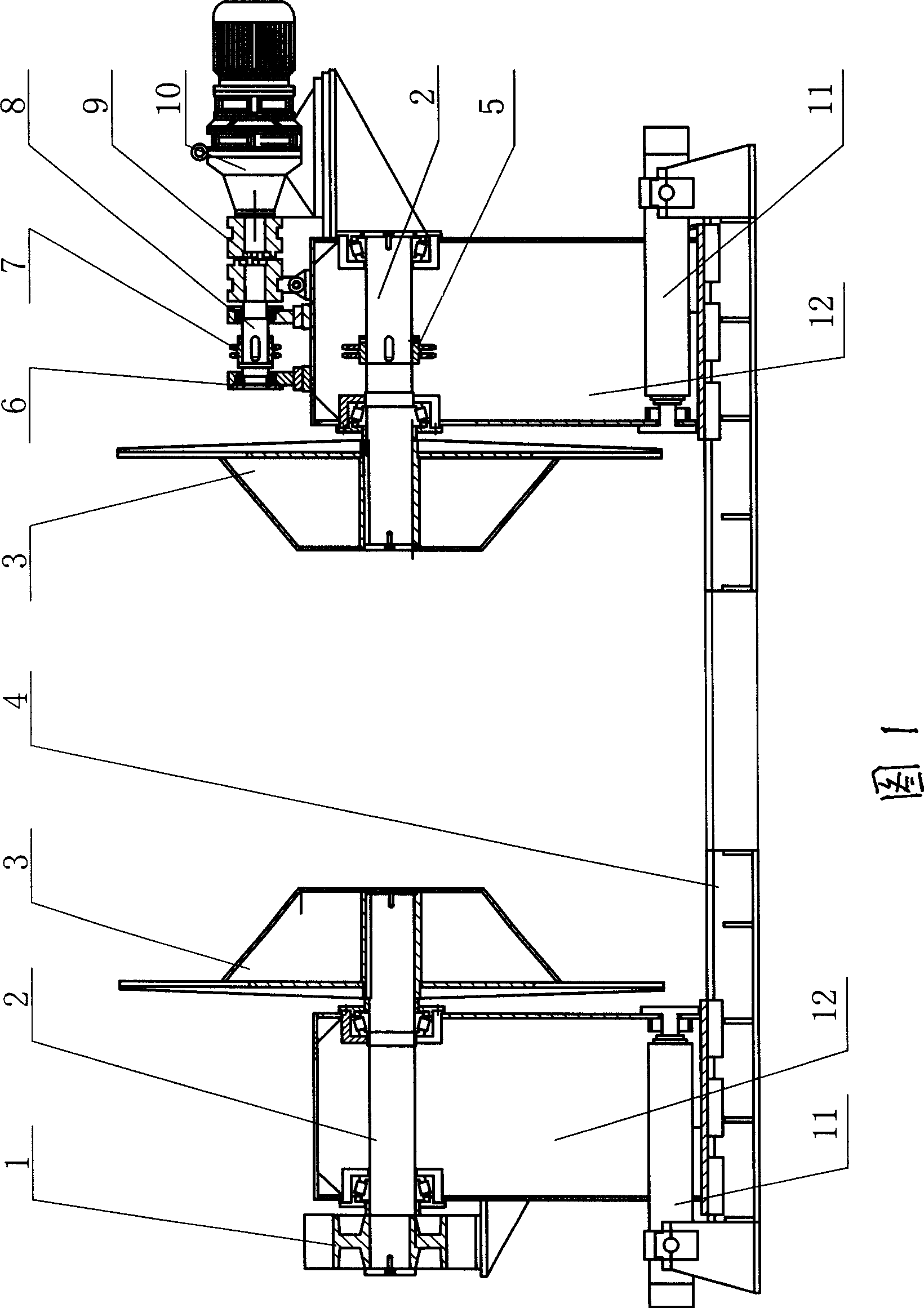

[0008] See Fig. 1, the present invention comprises machine base 4, and screw mandrel 11 is installed respectively at the two ends of machine base 4, and screw mandrel 11 on both sides is connected with support 12 of corresponding side respectively, and support 12 connects conical frame 3 by rotating shaft 2 respectively, The support 12 on one side is equipped with the motor drive structure of the rotating shaft. The motor drive structure includes a motor 10 and a driving shaft 8, the motor 10 and the driving shaft 8 are installed on a bracket 12, and 6 is a bearing seat, the motor 10 is connected to the driving shaft 8 through a clutch 9, and the driving shaft 8 is connected to the rotating shaft through the pulleys 5, 7 and a belt 2 and 1 are positioning discs.

[0009] Describe the working process of the present invention below in conjunction with accompanying drawing: during discharging, motor 10 drives driving shaft 8 by clutch 9, and driving shaft 8 drives rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com