Automobile with semi-automatic error correction braking system with inward rotating solenoid valve having fixed rotation angle

A brake system and solenoid valve technology, applied in the field of automobile brakes, can solve the problems of easily damaged solenoid valves, poor reliability, large frame size, etc., and achieve the effect of avoiding accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

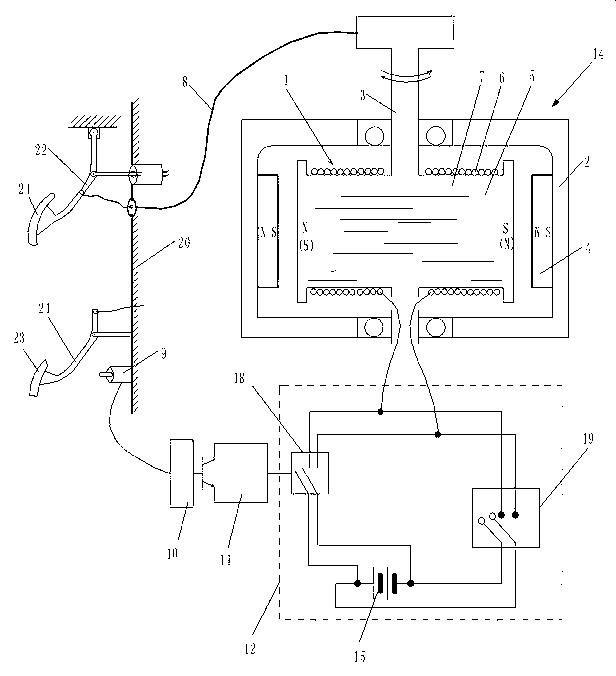

[0054] Embodiment 1, a car with a semi-automatic error correction braking system with an internally rotating fixed angle solenoid valve

[0055] like figure 1 , 2 , 3, including the gas pedal of the car and the gas linkage device 21, the brake pedal of the car and the brake linkage device 22, the car housing 20 under the gas pedal and the brake pedal of the car, and the error correction brake of the internal rotation type fixed angle solenoid valve system.

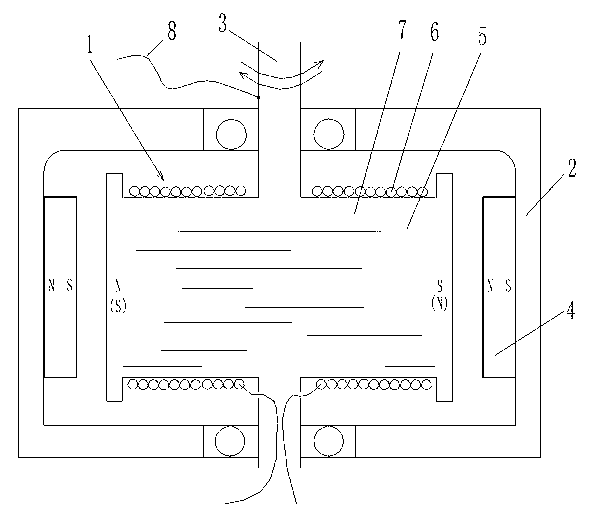

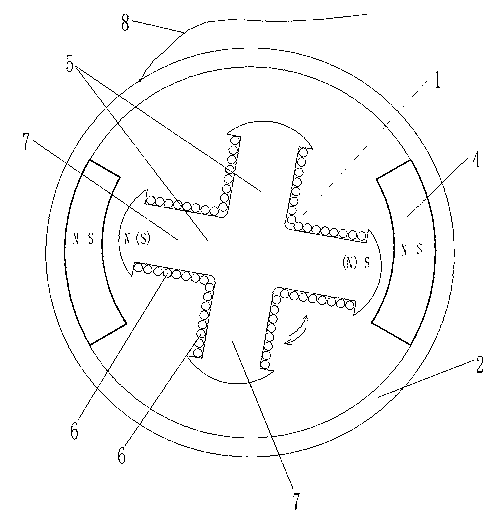

[0056] The structure of the error correction brake system of the internal rotation fixed angle solenoid valve is as follows:

[0057] The error correction braking system of the inner-turning fixed-angle solenoid valve includes a sensor 9---sensing signal analyzer 10---control signal power amplifier 11---power controller 12 connected sequentially for the purpose of transmitting electrical signals, and In order to convert electric energy into mechanical energy, the DC power supply 15 that is connected with the inner fork-...

Embodiment 2

[0071] Embodiment 2, a car with a semi-automatic error correction braking system with an internally rotating fixed angle solenoid valve

[0072] As in embodiment 1, but the error correction braking system of the internal rotation type fixed angle solenoid valve and the gas pedal 23, and the connection structure of the brake pedal are as follows:

[0073] The pressure sensor 9 and the speed sensor 9 of the error correction braking system of the inner-turning fixed-angle solenoid valve are arranged on the side of the accelerator pedal and the accelerator pedal 23 of the accelerator linkage device 21 facing the car shell 20, or the sensor 9 is arranged on the side close to the accelerator pedal. 23 on the automobile shell 20, and facing the gas pedal 23, so that in the emergency state of braking, when the driver steps on the gas pedal 23 with too much force, the pressure sensor 9 can feel the power of the gas pedal 23, and the speed sensor 9 can feel the speed of movement of the ...

Embodiment 3

[0074] Embodiment 3, a car with a semi-automatic error correction braking system with an internally rotating fixed angle solenoid valve

[0075] As in embodiment 1, but the error correction braking system of the internal rotation type fixed angle solenoid valve and the gas pedal 23, and the connection structure of the brake pedal are as follows:

[0076] The pressure sensor 9 and the speed sensor 9 of the error correction braking system of the inner-rotating fixed-angle solenoid valve are located at a position close to the throttle linkage device, and a fixed auxiliary contactor is set on the throttle linkage device, and the displacement of the throttle linkage device drives the displacement of the auxiliary contactor. In contact with the pressure sensor 9, the pressure sensor 9 is used to feel the throttle linkage device to set the motion force. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com