A Concrete Pipe Die for Radial Extrusion Forming Process

A concrete pipe, extrusion molding technology, applied in the direction of molds, etc., can solve the problems of manual mold loading and low efficiency, and achieve the effect of easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

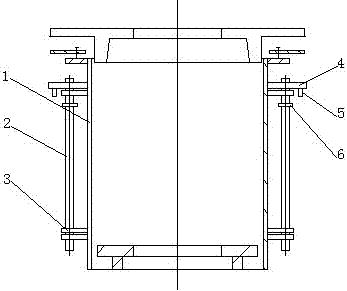

[0013] The present invention includes a cylinder body 1, and the side of the cylinder body 1 is provided with a hinge mechanism along the longitudinal direction;

[0014] The hinge mechanism includes a hinge shaft 2 arranged parallel to the cylinder body 1, the hinge shaft 2 is connected to the cylinder body 1 through a hinge 3, and a movable shaft 4 connected to the cylinder body 1 is provided on the hinge shaft 2. The movable shaft 4 is provided with Force lever 5.

[0015] A shaft shoulder 6 is arranged on the middle and upper part of the hinge shaft 2 .

[0016] The lower surface of the shoulder 6 is provided with convex points arranged evenly.

[0017] The cylinder body 1 of the present invention is longitudinally divided into three parts along the circumference, two of which are connected by a hinge 3, and a hinge shaft 2 is arranged at the hinge 3, and a shaft shoulder 6 is arranged on the top of the hinge shaft 2. The present invention can use a Y-shape on a forklift....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com