Concrete pipe anti-leak treatment technique and special device

The technology of concrete pipe and treatment process is applied in the field of concrete pipe anti-seepage process and special equipment, which can solve the problems of difficult to complete the repair of the nozzle, high repair cost, labor-intensive and labor-intensive, etc., so as to achieve the low cost of impermeable treatment and the improvement of production efficiency. , the effect of improving the repair speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

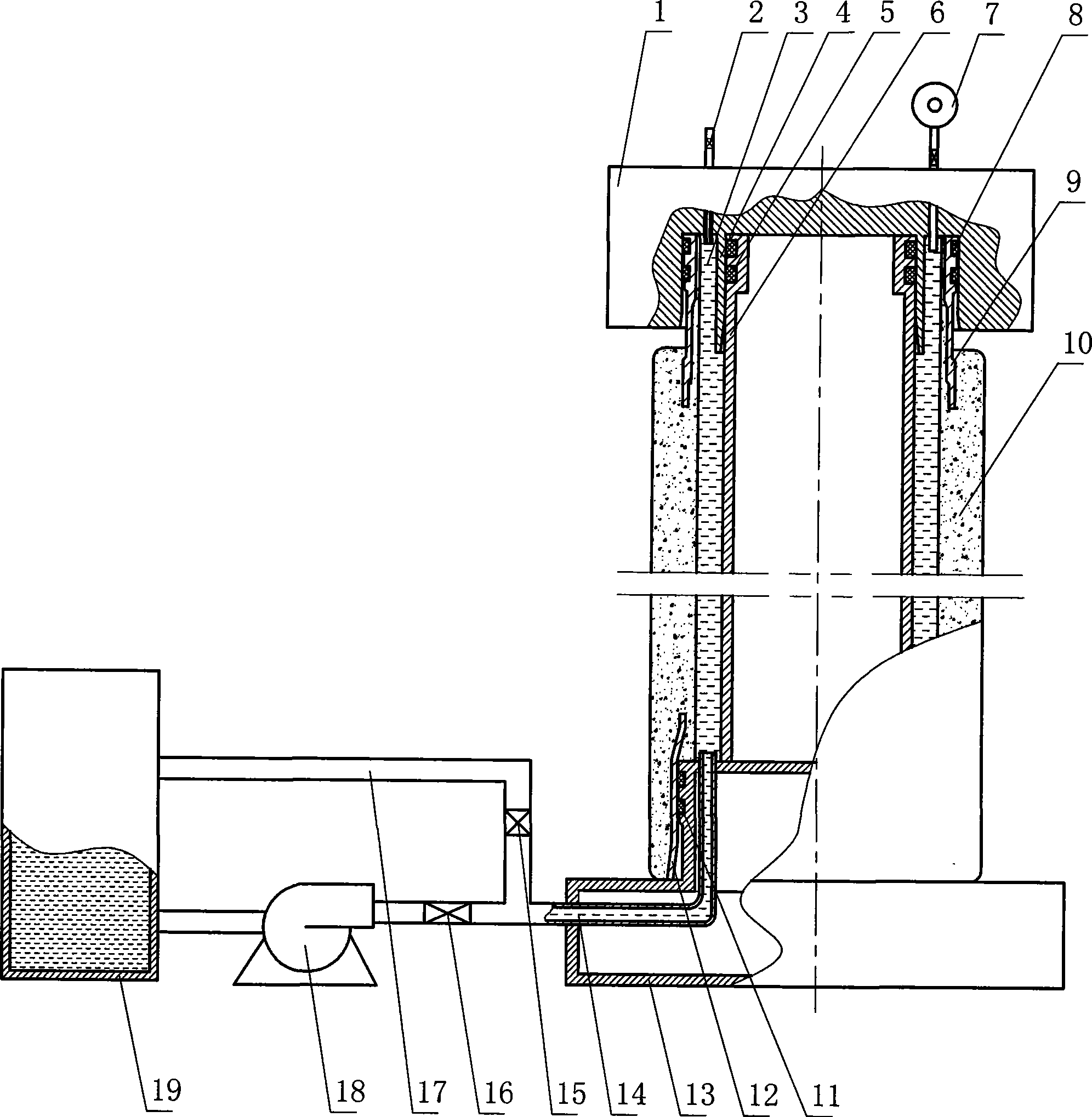

[0022] In order to describe the embodiment of the present invention more clearly, at first describe the special equipment of this concrete pipe anti-seepage process.

[0023] The main body of this special equipment is composed of a base 13, a steel cylinder liner 6, a cover 1, a liquid storage tank 19, a liquid injection pump 18, and a return pipeline 17, wherein the base, the steel cylinder liner, and the cover are installed coaxially and vertically , the lower end of the steel cylinder liner is coaxially fixed on the upper plane of the base and a seal ring 11 for sealing the concrete socket is installed on the outer cylindrical surface of the upper half of the base, and a Liquid injection pipeline 14, the inlet end of the liquid injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com