Suspension structure of engine

A technology for engine mounts and engines, which is applied in the direction of power plants, jet propulsion devices, internal combustion propulsion devices, etc., can solve the problems of uneconomical, complicated vibration reduction structure of the secondary mount, and large space occupation, so as to reduce manufacturing difficulty and The effect of manufacturing cost, meeting NVH performance requirements, and saving layout space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

[0015] see Figure 4 , the engine mount structure retains the original left and right mounts 13 and 14, which are still connected to the vehicle body respectively (the body is not shown in the figure), while the front and rear are not connected to the sub-frame, and the front mount is canceled, only A rear suspension 11 is arranged at the rear bottom of the engine, one end is connected to the engine 9, and the other end is connected to the vehicle body.

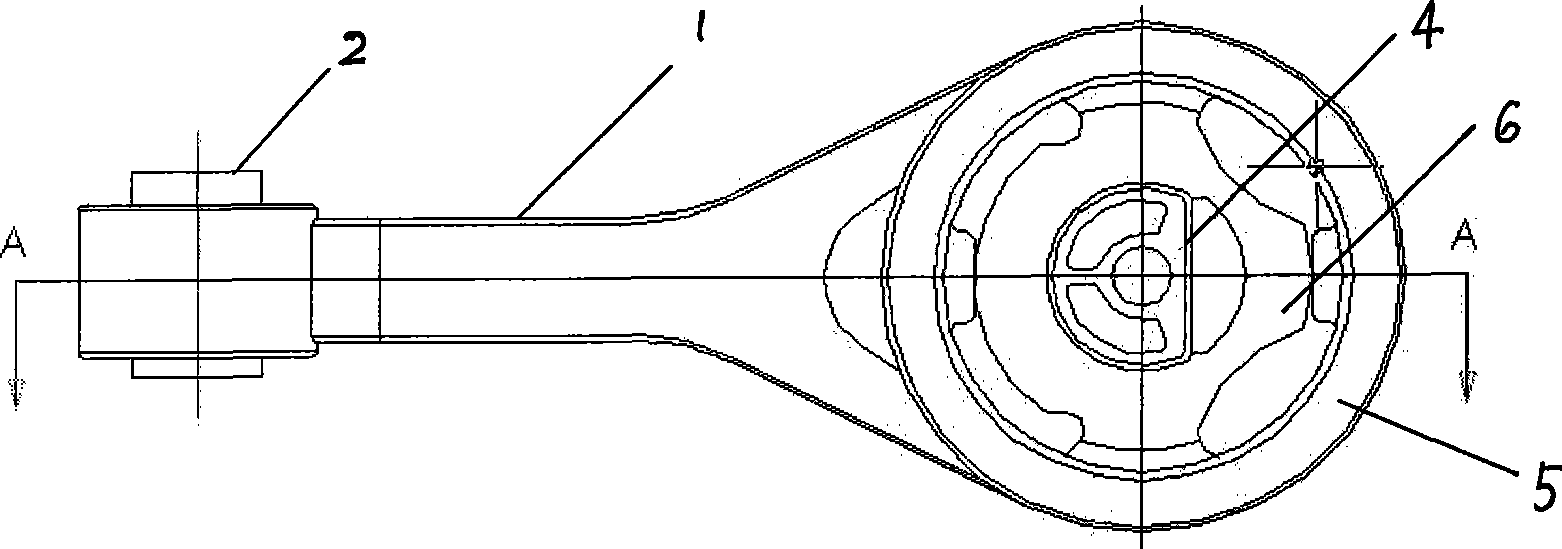

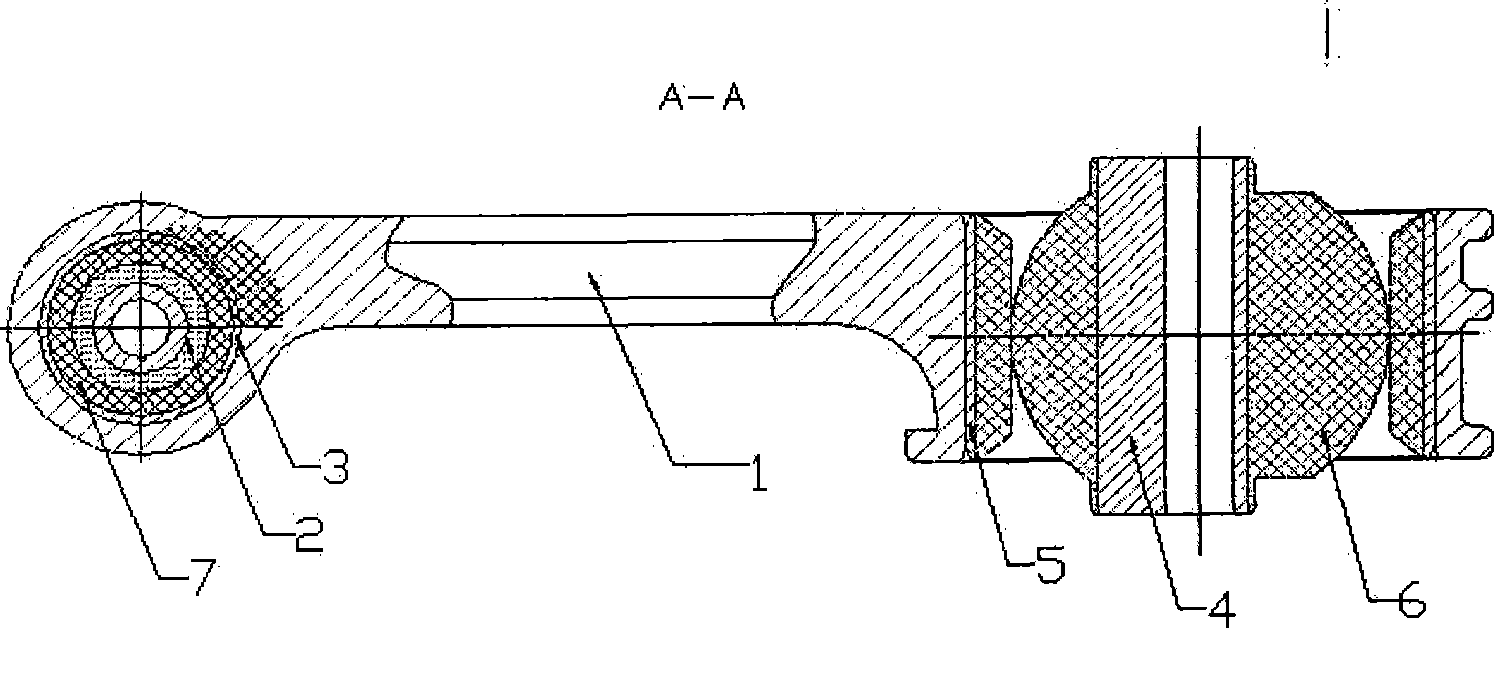

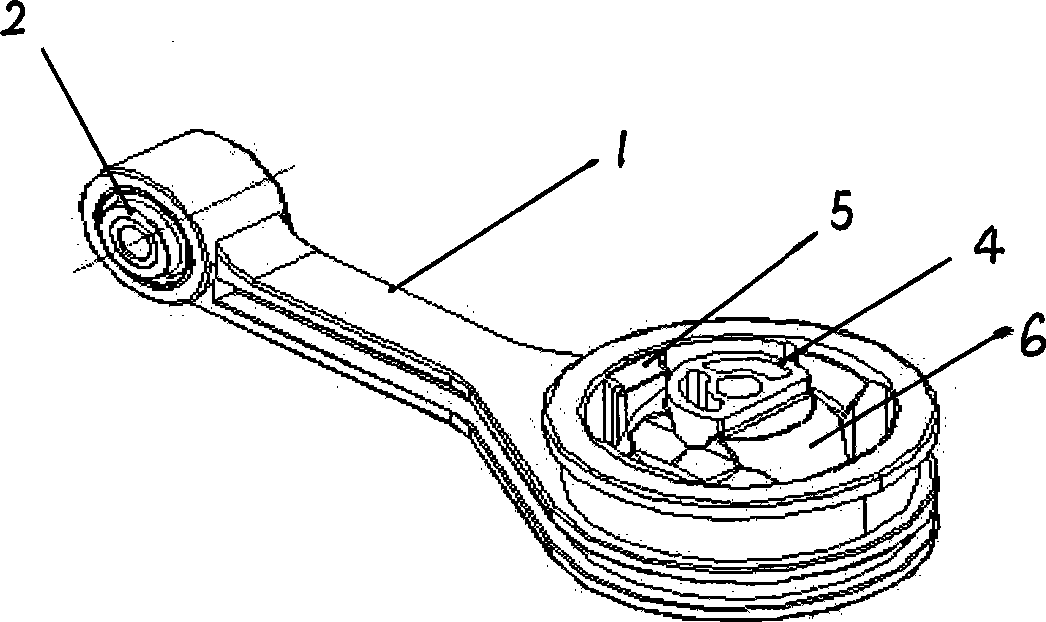

[0016] see figure 1 , figure 2 and image 3 , the rear suspension includes an aluminum alloy bracket 1, a small-end inner tube 2, a small-end bushing 3, a large-end inner tube 4, a big-end bushing 5, a large-end vibration-damping rubber 6, and a small-end vibration-damping rubber 7. The specific setting can be seen in the cross-sectional view of the large and small ends of the present invention. The small end inner t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com