Flame retardant aromatic polycarbonate resin composition

A technology of polycarbonate resin and resin composition, applied in the field of flame retardant resin composition, can solve undisclosed and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

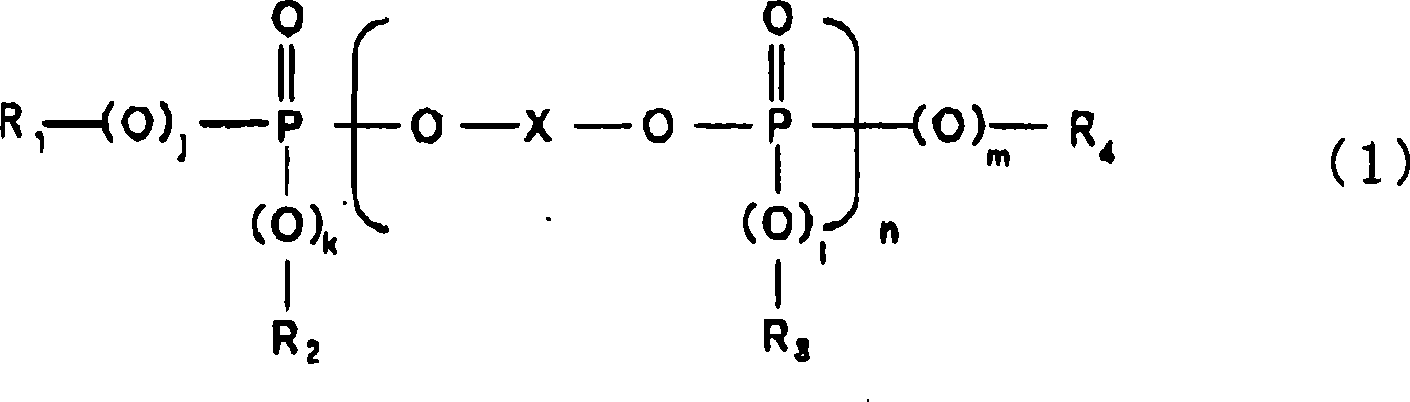

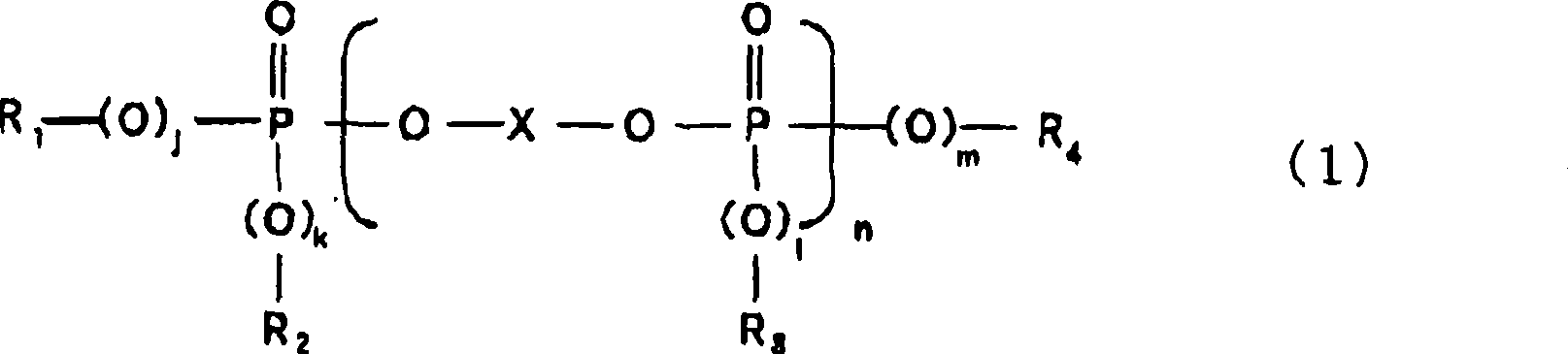

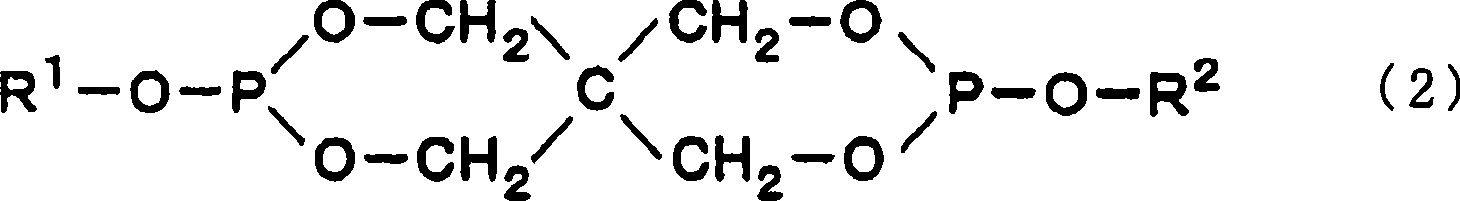

Method used

Image

Examples

preparation example Construction

[0077] As the preparation method of MBS resin, it can carry out by various methods, such as bulk polymerization, suspension polymerization, and emulsion polymerization, for example. Especially preferred is the emulsion polymerization method. The thus obtained core-shell graft rubbery elastomer preferably contains 50% by weight or more of the aforementioned rubber component. The content of the unsaturated alkyl carboxylate-diene rubber-aromatic vinyl graft copolymer (component F) is preferably 0.1 to 10 parts by weight based on 100 parts by weight of the total of components A and B , more preferably 0.5 to 7 parts by weight, even more preferably 1 to 5 parts by weight.

[0078] Examples of commercially available MBS resins include Metabren C-223A (trade name, manufactured by Mitsubishi Rayon Co., Ltd.), Pararoid EXL-2638 (trade name, manufactured by Rom & Haus Co., Ltd.), and the like.

[0079] (Component G: Inorganic filler)

[0080] In the present invention, various inorga...

Embodiment 1~5、 comparative example 1~5

[0166] With the composition shown in Table 1, a mixture containing the components of the ABS resin other than the C component, the B component, and the B component was supplied from the first supply port of the extruder. The mixture is obtained by mixing the premix of (i) and other ingredients with a V-type mixer. That is, (i) is a mixture of component D (fluorine-containing anti-dripping agent) and aromatic polycarbonate of component A, and is a mixture in which component D is 2.5% by weight by vibrating the entire bag in a polyethylene bag. Component B and ABS resins other than component B were supplied from the second supply port using a side feeder. Further, FR of component C was heated to 80°C from the third supply port (located between the second supply port and the discharge port) in the middle of the cylinder using a liquid injection device (HYM-JS-08 manufactured by Fuji Techno Industry Co., Ltd.). Between the gas ports) to the extruder to achieve the specified ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com