High-strength hot-dip zinc-coated steel sheet

A hot-dip galvanized steel sheet, high-strength technology, applied in the direction of hot-dip galvanizing process, process efficiency improvement, transportation and packaging, etc., can solve the problem of reduced formability and other problems, and achieve excellent formability, light weight and anti-rust Favorable, good effect on the appearance of the plated surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

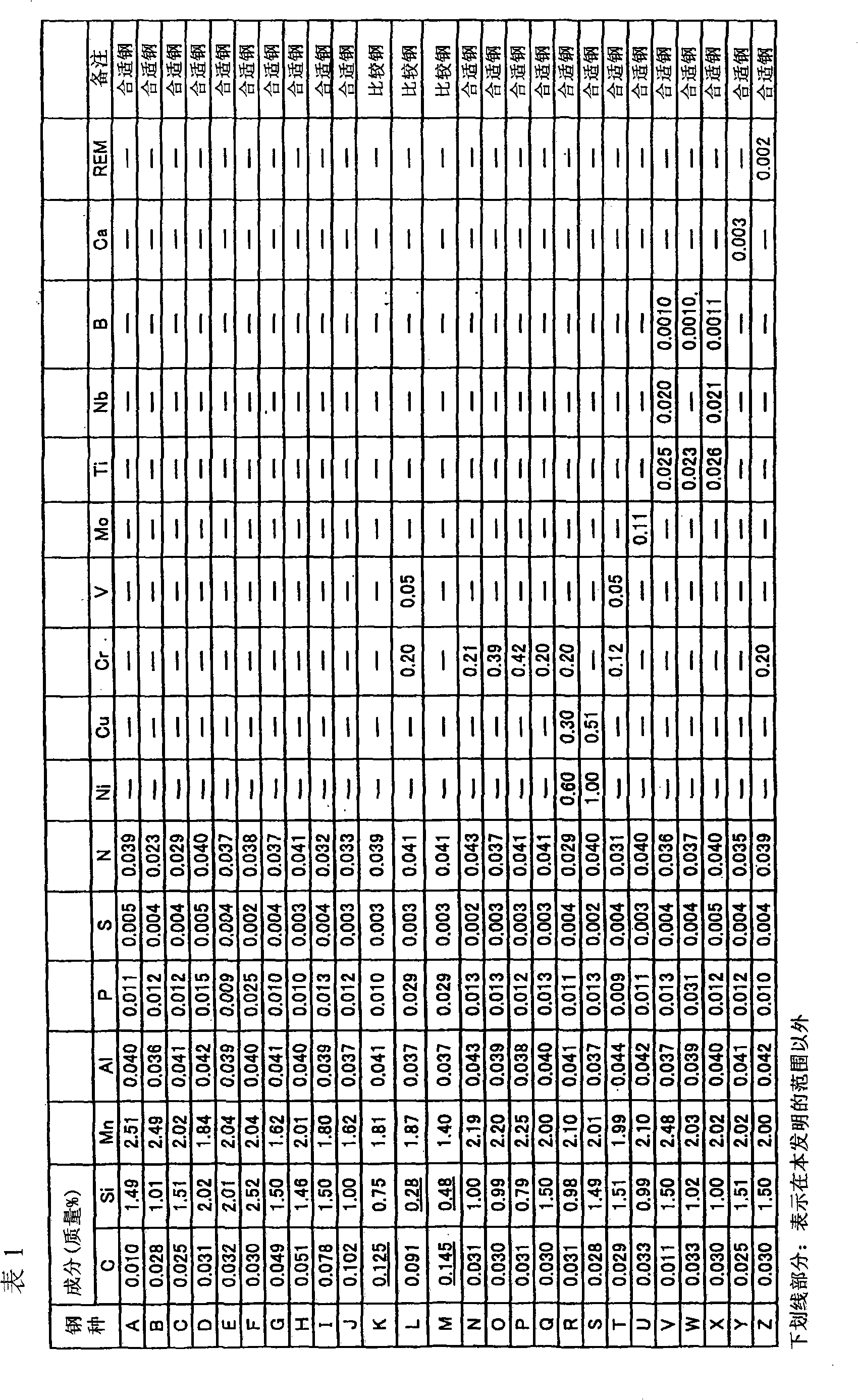

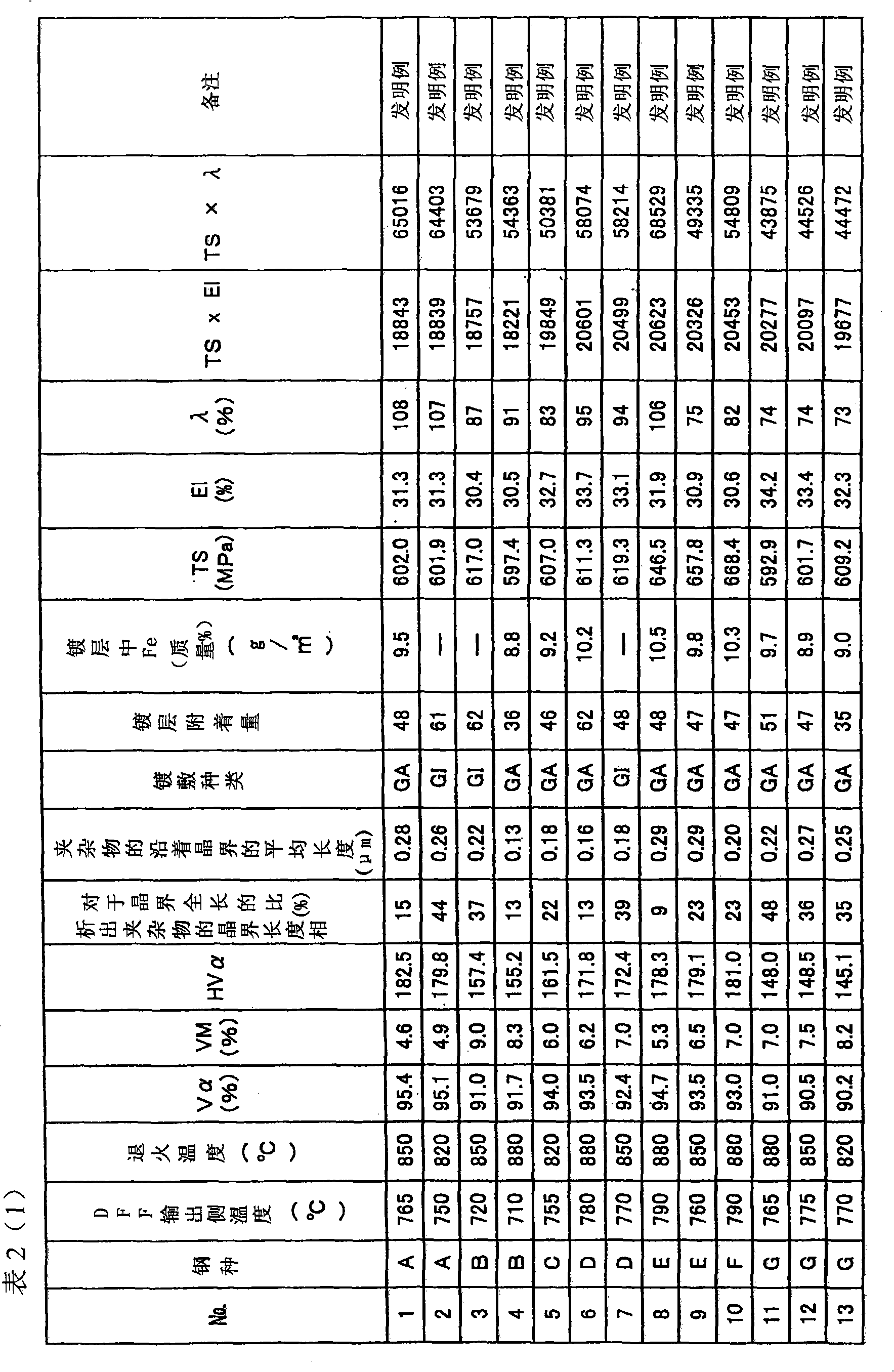

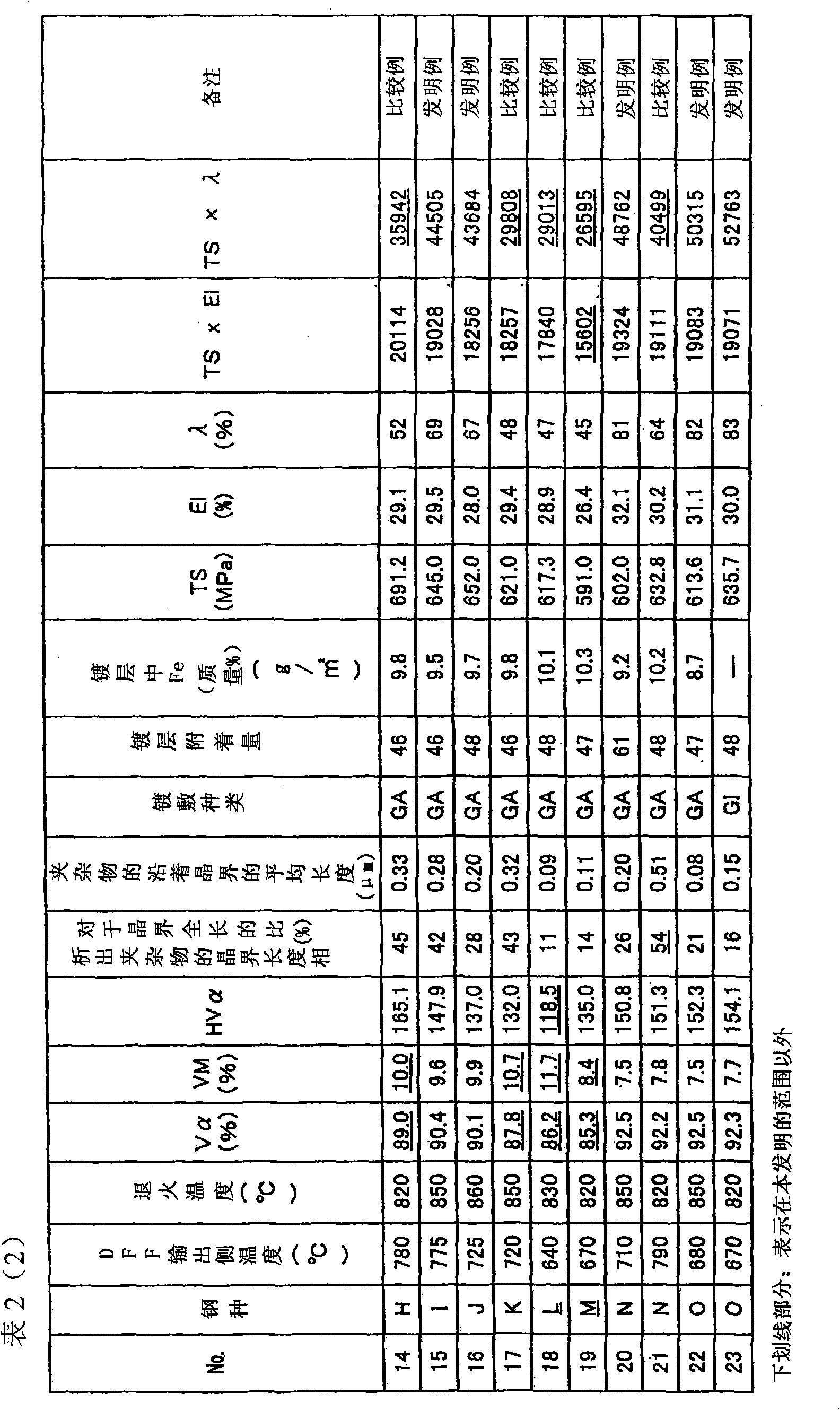

[0130] Cast slabs obtained by melting steels having the chemical compositions shown in Table 1 were hot-rolled, pickled, and then cold-rolled to form cold-rolled steel sheets with a thickness of 1.2 mm. Then, in a continuous hot-dip galvanizing line with a DFF furnace (Direct Fired Furnace), the air ratio in the DFF furnace is controlled to 1.0 to 1.2 on the upstream side and 0.9 on the downstream side. Change the temperature on the output side of the DFF furnace, heat it up, heat treatment in the austenite single-phase region or two-phase region, and then use a galvanizing bath at 463°C to implement a coating amount of about 40-60g / m on each side 2 Plating, and alloying treatment, so that the Fe% of the plating layer as the target condition becomes about 10% by mass. When adjusting the degree of alloying, the passing speed and alloying temperature should be changed appropriately. 0.3% temper rolling was performed on the obtained steel sheet.

[0131]

[0132] Here, 10 fi...

Embodiment 2

[0146] Steel slabs obtained by melting steels having the composition of steels C, E, and H shown in Table 1 were hot-rolled, then pickled, and then cold-rolled to form cold-rolled steel sheets with a thickness of 1.2 mm. Then, on a continuous hot-dip galvanizing production line with a DFF furnace (Direct Fired Furnace), continuous annealing was carried out according to the annealing conditions (DFF furnace output side temperature, annealing temperature, cooling stop temperature) shown in Table 3, Then use a galvanizing bath at 463°C to apply a coating amount of about 40-60g / m on one side 2 Plating and alloying treatment of the coating. 0.3% temper rolling was performed on the obtained steel sheet. In addition, the air ratio in the DFF furnace in the heating stage was controlled to be 1.0 to 1.2 on the upstream side and 0.9 on the downstream side.

[0147] For the hot-dip galvanized steel sheets thus obtained, the microstructure, hardness, and mechanical property values (te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com