Rotating dynamical type multiphase booster pump

A technology of rotary power and booster pump, applied in the field of multiphase pump, can solve the problems of limited use range, reduced efficiency, large volume and other problems of multiphase pump, and achieve the effect of good performance under variable working conditions and convenient disassembly, assembly and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be described in detail below with reference to the drawings and embodiments.

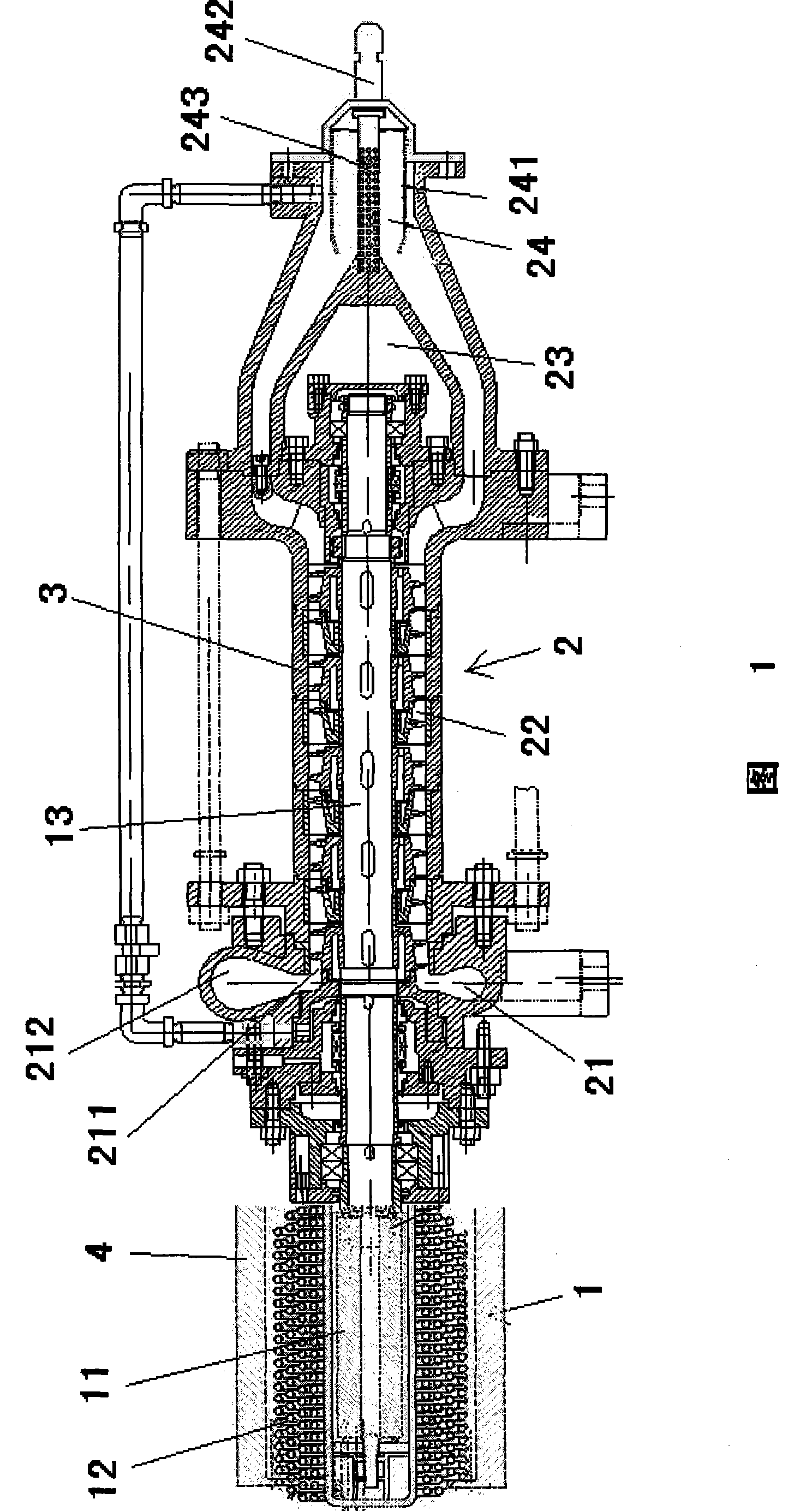

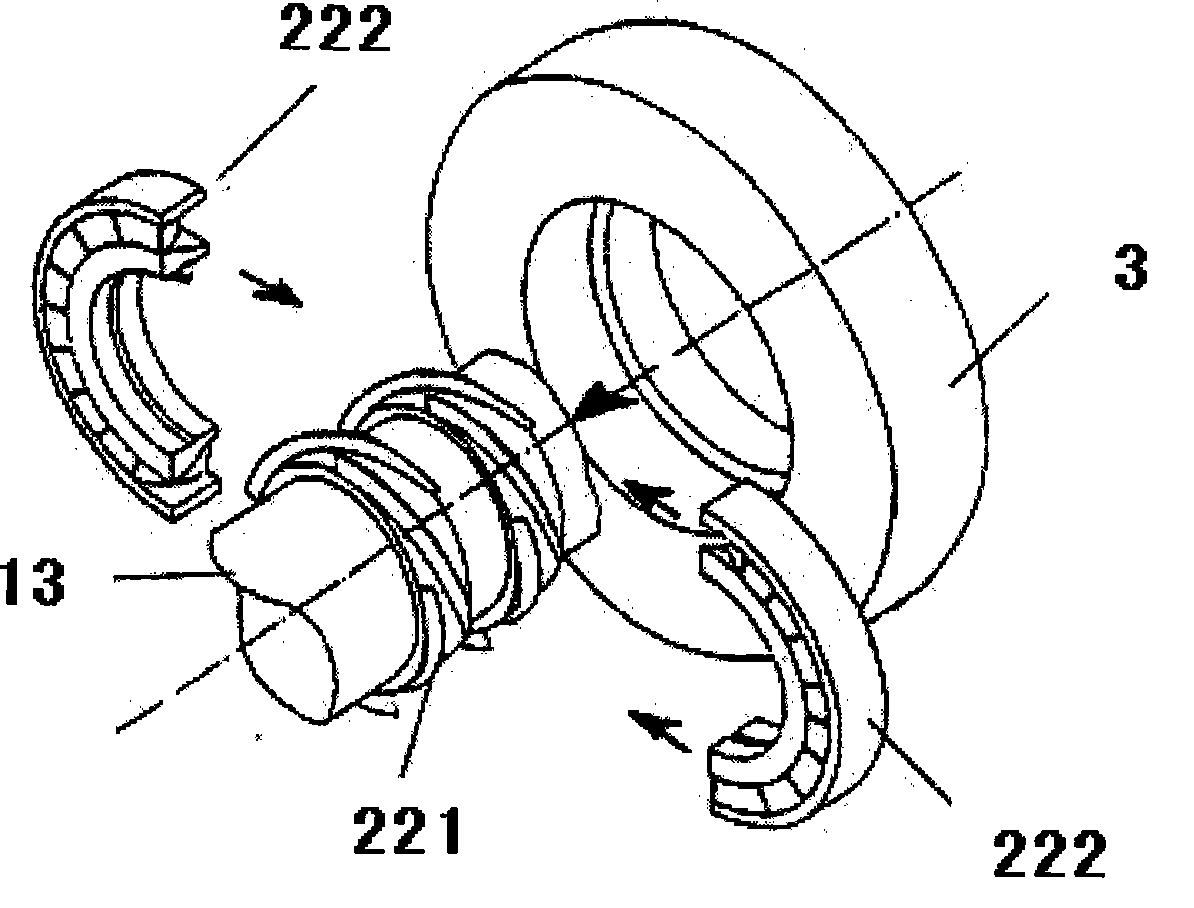

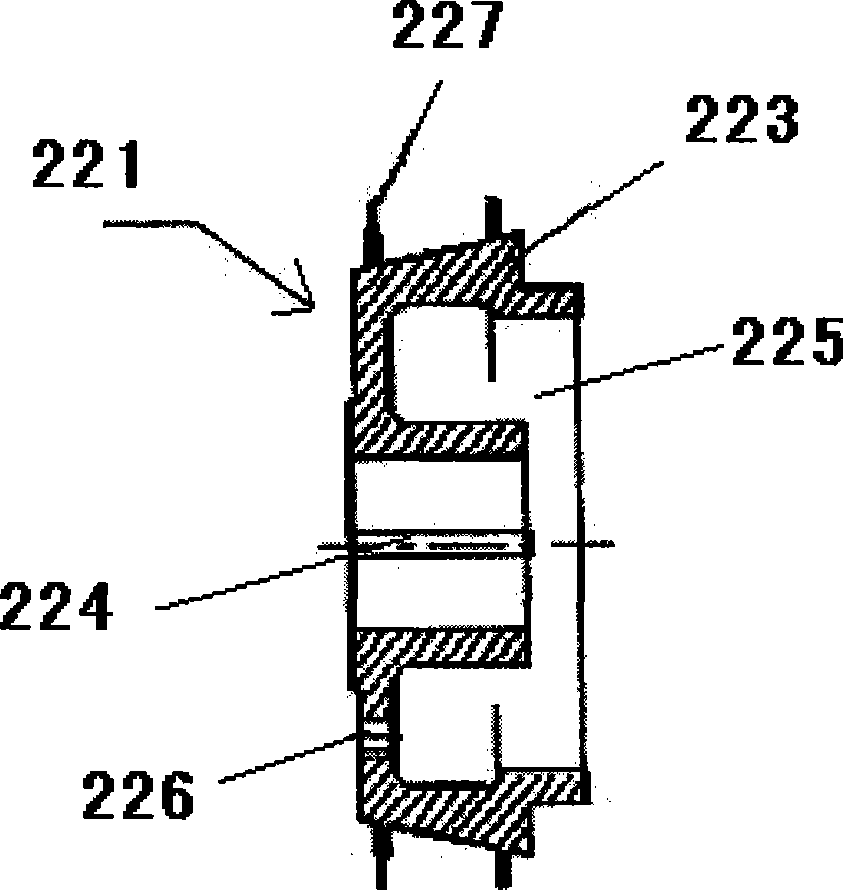

[0021] As shown in Figure 1, the present invention is a shaft connection structure, including a power unit 1, a pump body 2 driven and connected by the power unit 1, and other auxiliary devices, such as bearings, auxiliary fixing parts, connectors, and sealing systems , Lubrication system, etc.

[0022] The power device 1 of the present invention is driven by a high-speed frequency conversion explosion-proof motor 11. In order to effectively absorb the heat generated by the motor 11 due to its operation, a cooling coil 12 is provided on the periphery of the motor 11. The motor 11 is electrically connected with pressure, temperature, flow and other measurement and control devices installed at the inlet and outlet of the pump body 2. The operator can control the motor 11 through the operation panel connected with the measurement and control device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com