Blade type oil, gas and water multiphase booster pump

An oil-gas-water, vane-type technology, applied in the field of multi-phase booster pump, vane-type oil-gas-water multiphase booster pump, can solve the problems of sensitivity to solid particles, large size and weight, loss of pressurization ability, etc., to improve performance , saving equipment and pipeline construction costs, and optimizing the effect of design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

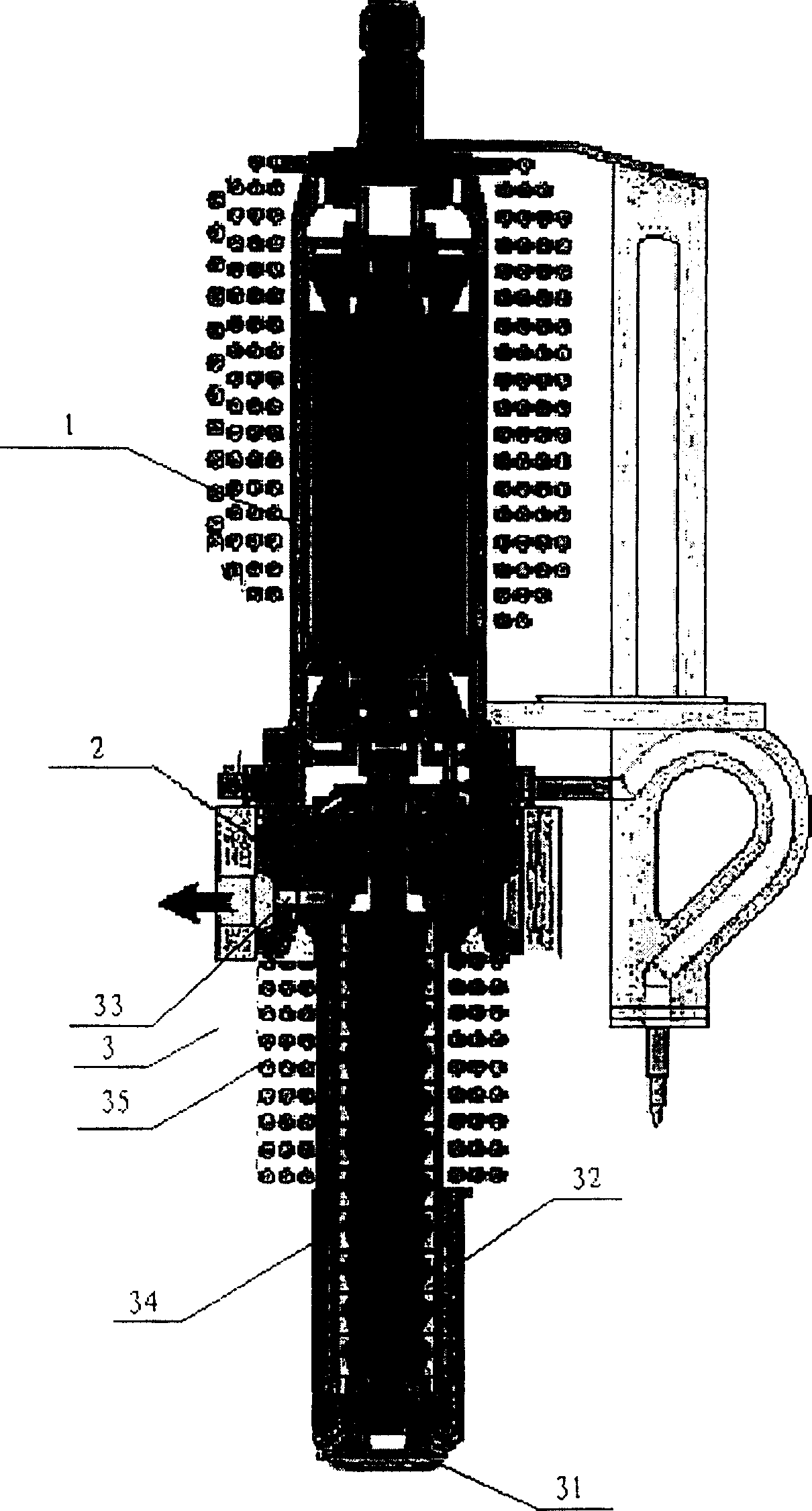

[0039] Such as figure 1As shown, it is a structural schematic diagram of the vane type oil-gas-water multiphase booster pump of the present invention. It can be seen from the figure that in order to adapt to the application of offshore platforms and future deep-water oil fields, the entire vane multiphase pump adopts a vertical design, mainly composed of a power unit 1, a seal, a bearing unit 2 and a booster unit 3, and the power unit 1 passes through the seal. , the bearing device 2, the shaft coupling and the supercharging device 3 are connected. The multi-phase booster pump requires the rotating shaft to rotate at high speed, so usually the power unit 1 adopts a high-speed frequency conversion explosion-proof motor.

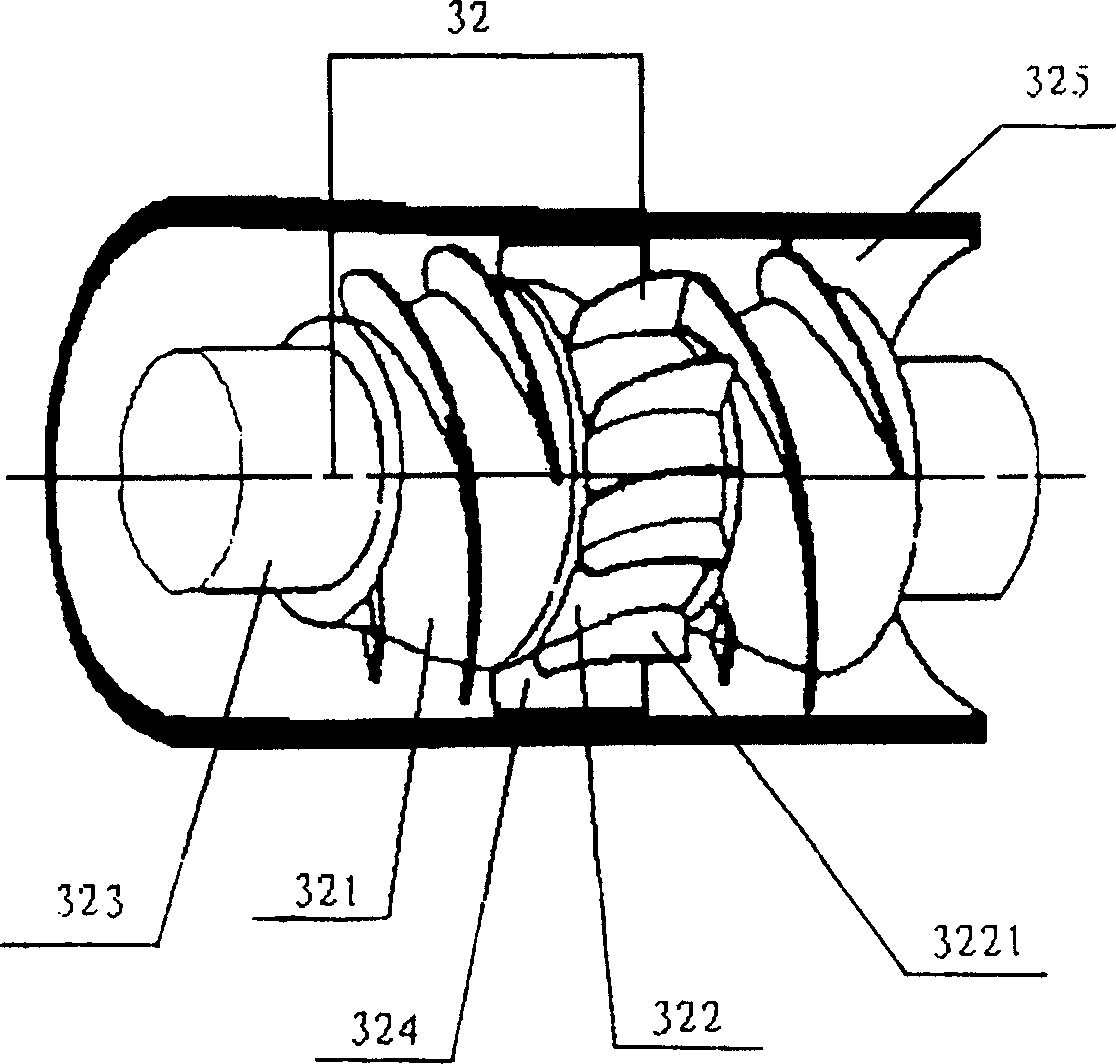

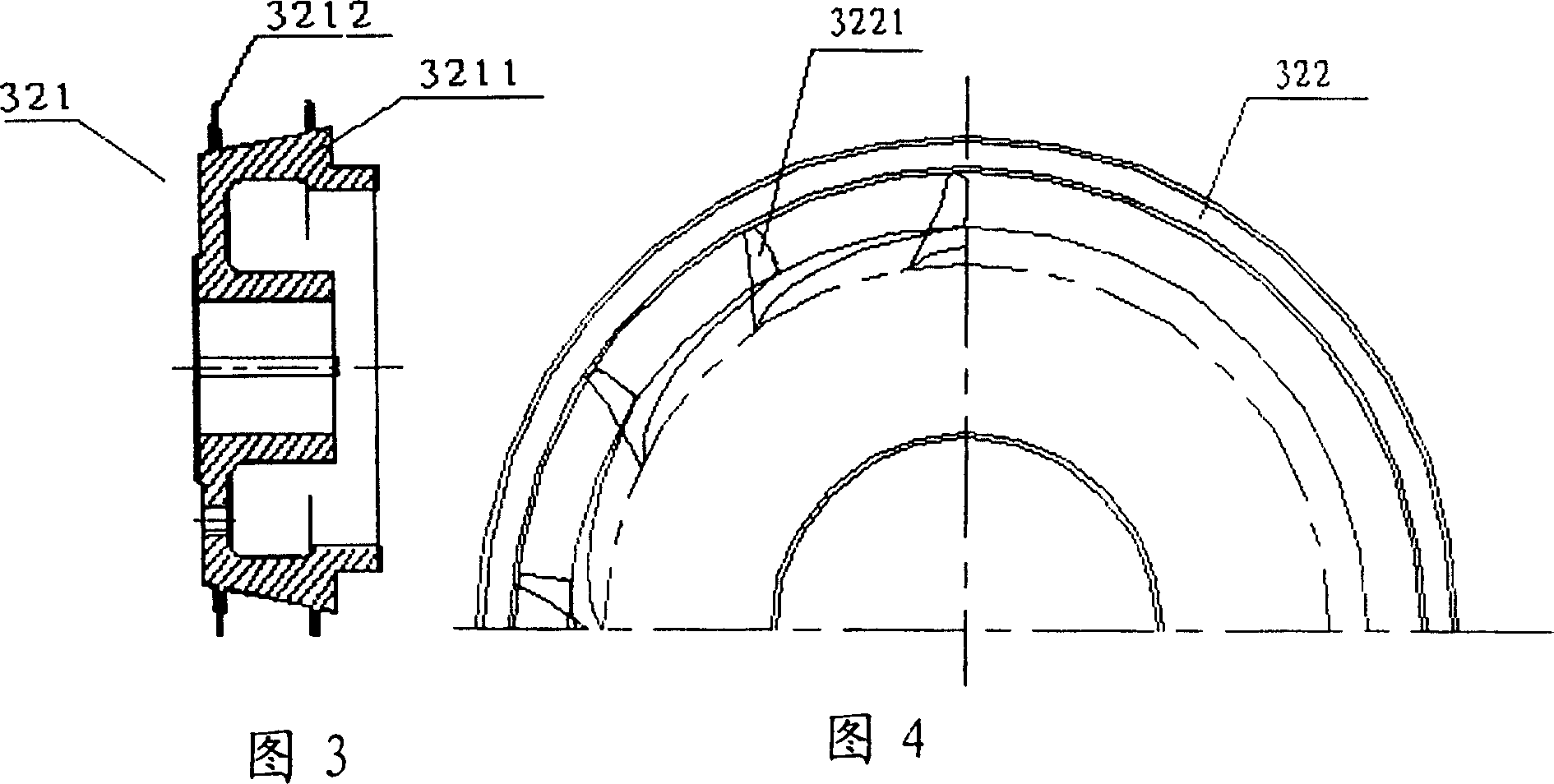

[0040] The supercharging device 3 includes a suction unit 31, a multiphase supercharging unit 32, a final diffuser section 33, a pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com