LED illuminating device

A light-emitting device, LED chip technology, applied in lighting devices, lighting device parts, semiconductor devices of light-emitting elements, etc., can solve problems such as discomfort, human eye glare, eye fatigue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to describe the structure and characteristics of the present invention in detail, the following two preferred embodiments are given below and described in conjunction with the drawings, wherein:

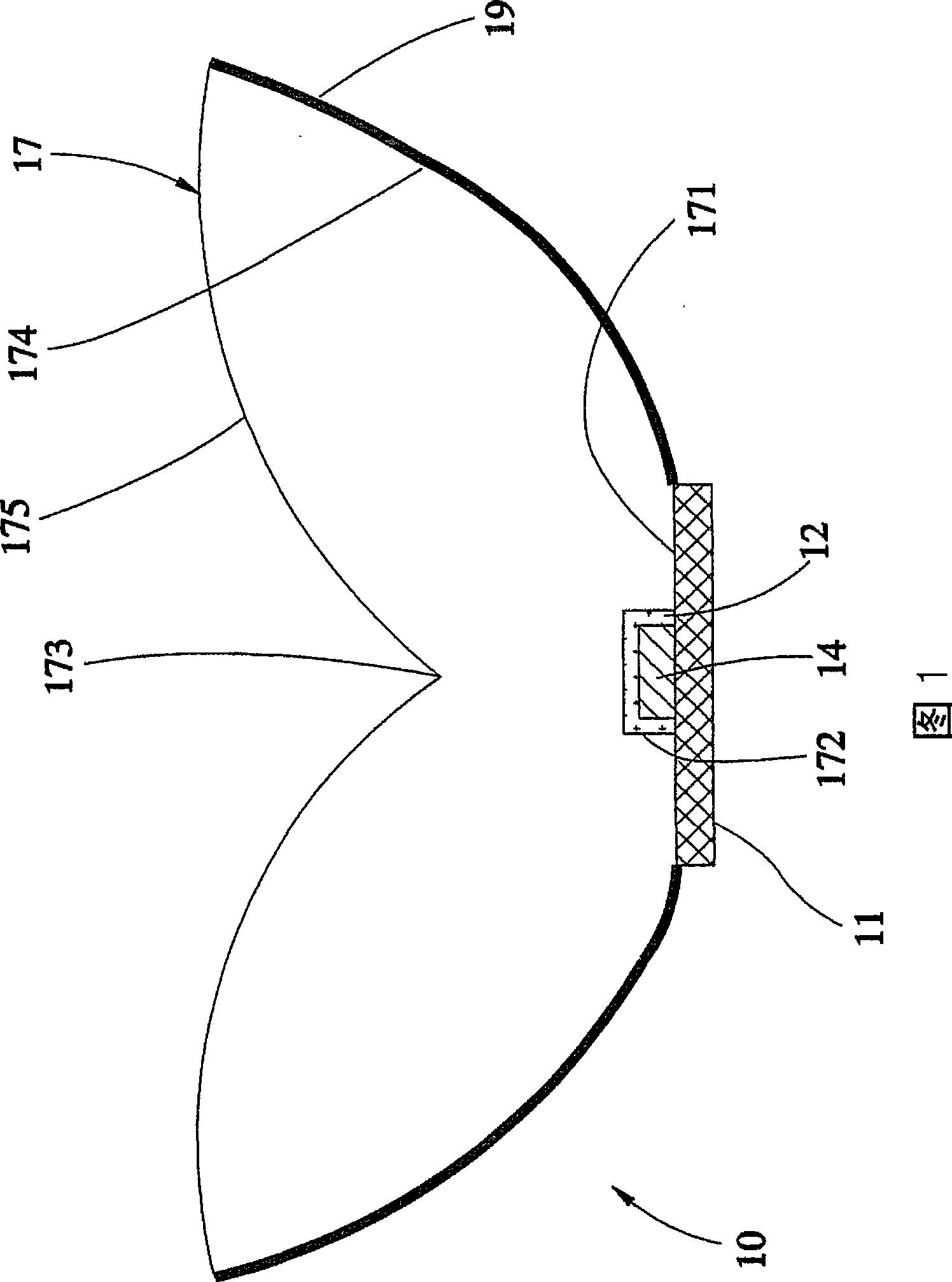

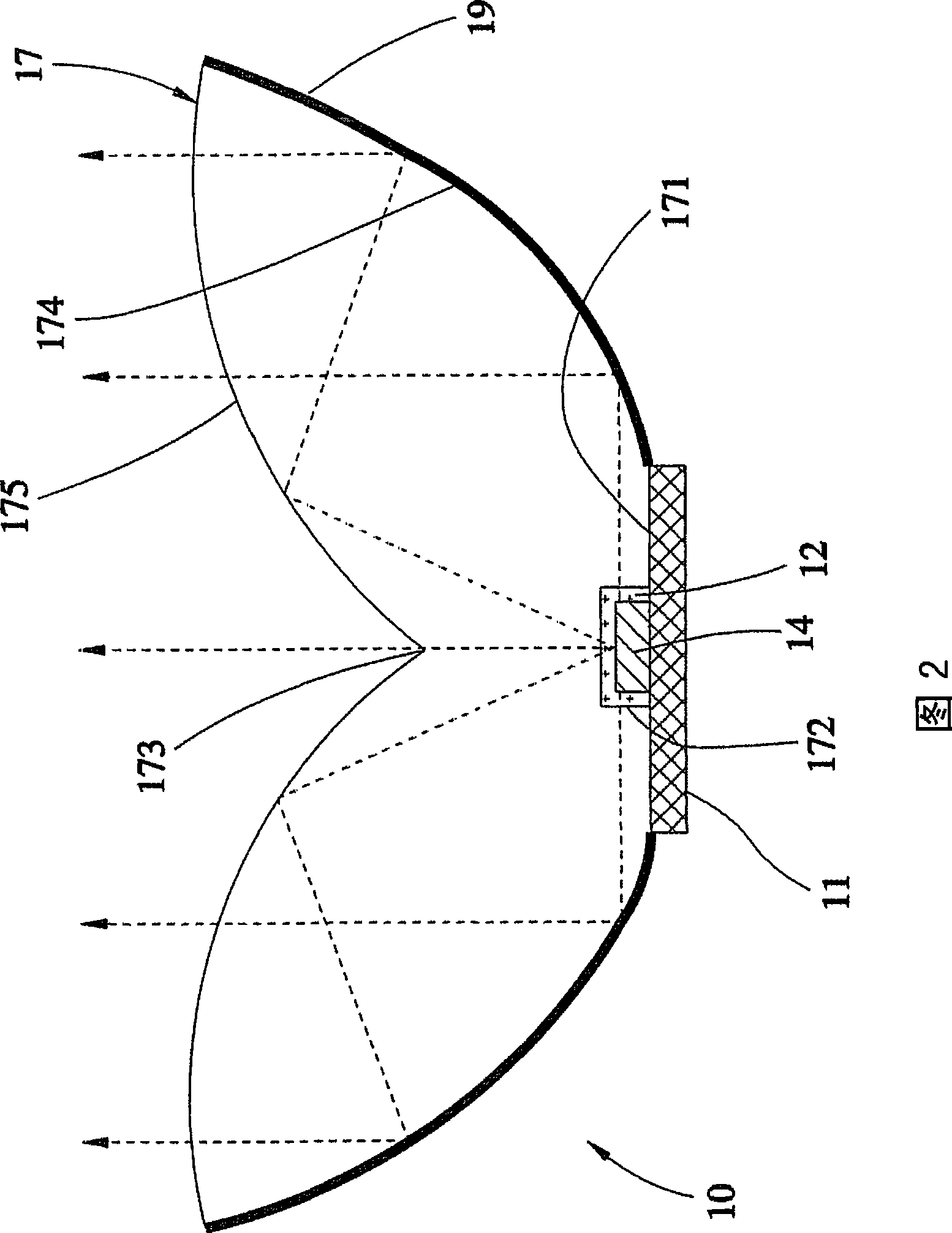

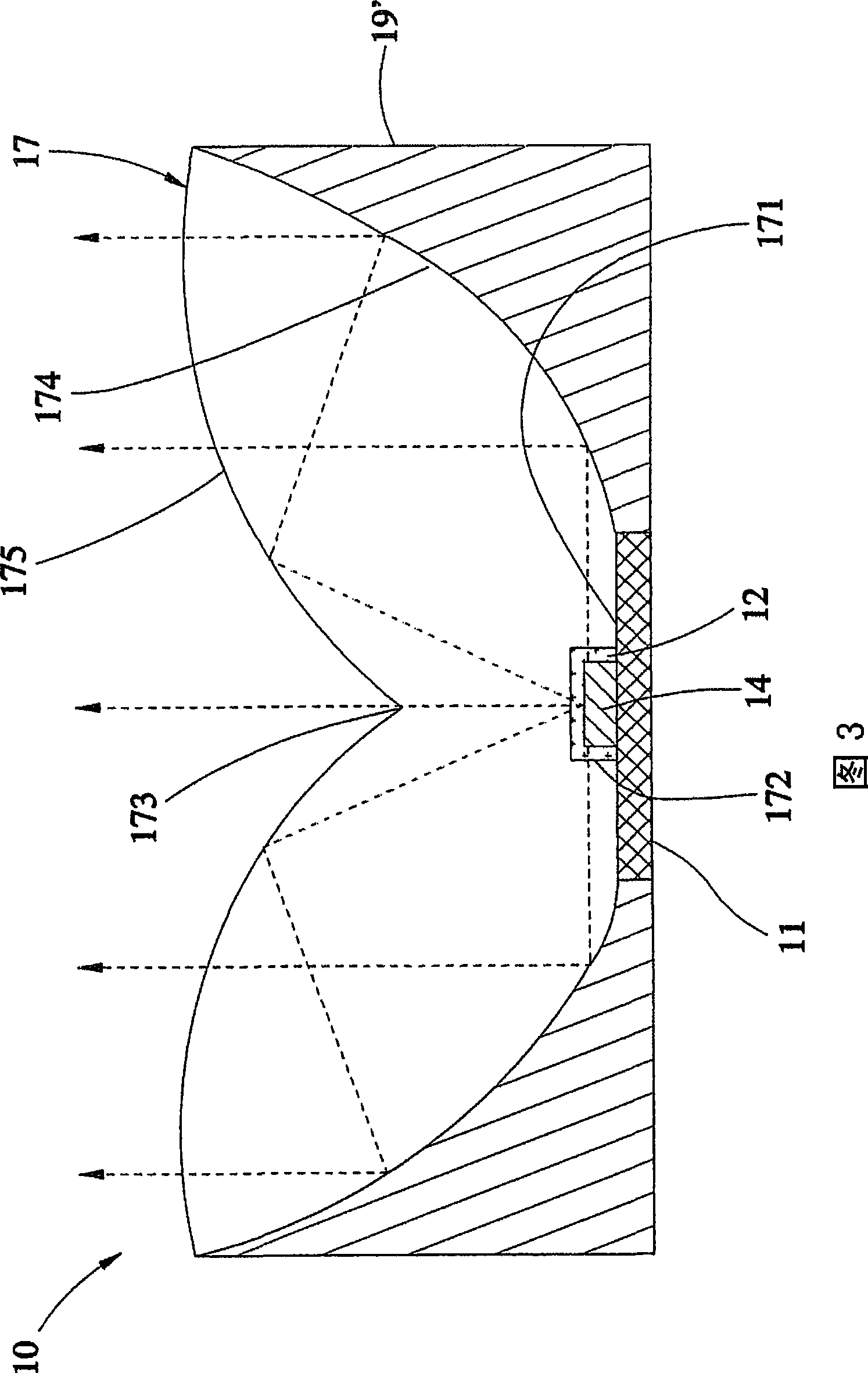

[0029] As shown in Figures 1 to 2, an LED lighting device 10 provided by the first preferred embodiment of the present invention is mainly composed of a substrate 11, an LED chip 14 and a lens 17, wherein:

[0030] The LED chip 14 is disposed on the substrate 11 .

[0031] The lens 17 has a mounting portion 171 on the bottom surface, and the mounting portion 171 has a groove 172 recessed upward. The lens 17 is arranged on the substrate 11 with its mounting portion 171, and the LED chip 14 is located in the groove 172. Inside. In actual manufacture, a buffer layer 12 can be arranged between the LED chip 14 and the lens 17, and its material can be silica gel or epoxy resin or other soft light-transmitting substances, and the buffer layer 12 is shown in each figure. Lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com